Multi-core cable wire testing method and device

A multi-core cable and testing device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as low efficiency, error-prone, and difficult to find poor contact, etc., to achieve high detection efficiency and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

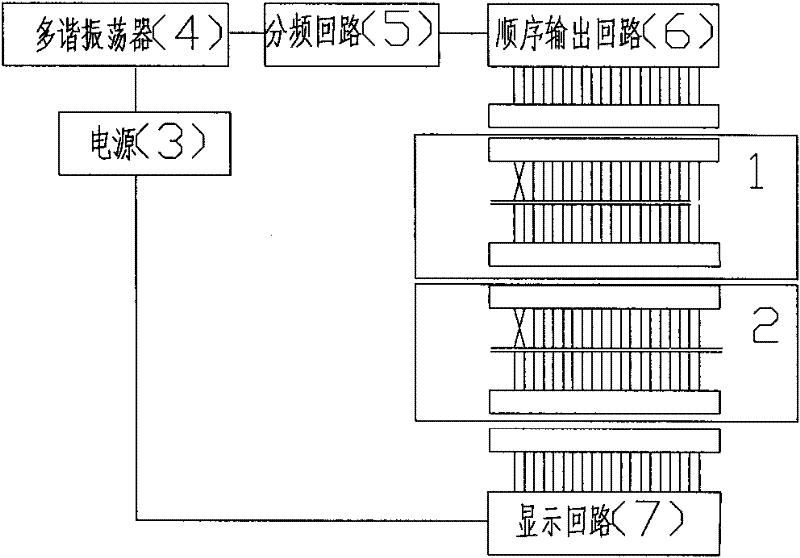

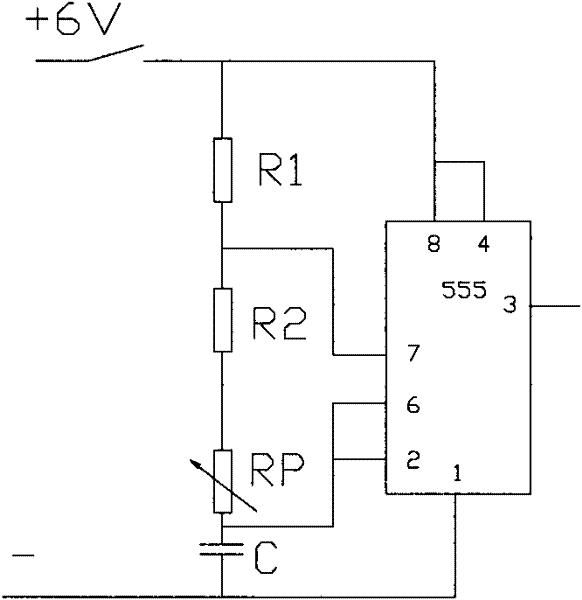

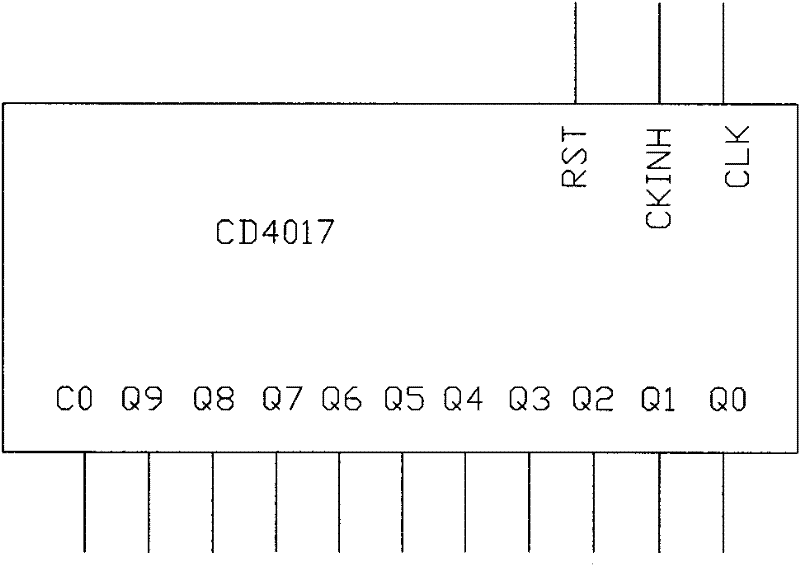

[0034] The multi-core cable test device of this embodiment includes a tester and a vibrator, and the tester includes an operation panel and a test circuit; see figure 1 , the test circuit includes a multivibrator 4, a frequency dividing circuit 5, a sequential output circuit 6, and a display circuit 7. The power supply 3 is a 6V dry battery to supply power for each circuit; the multivibrator 4, the frequency dividing circuit 5, and the sequence output circuit 6 Connect in series in sequence; the sequence output loop 6 and the display loop 7 are connected in series by the tested multi-core cable 1 and the transfer multi-core cable 2 . see figure 2, the multivibrator 4 consists of a 555 timer and a resistor R1, a resistor R2, an adjustable resistor PR, and a capacitor C. One end of the resistor R1 is connected to the positive pole of the power supply, and the other end of the resistor R1 is connected in series with the resistor R2, the adjustable resistor RP, and the capacitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com