Use of a lubricant in an internal combustion engine

A technology for lubricants and applications, which is applied to the application field of lubricants in internal combustion engines, and can solve problems such as increasing fuel consumption and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

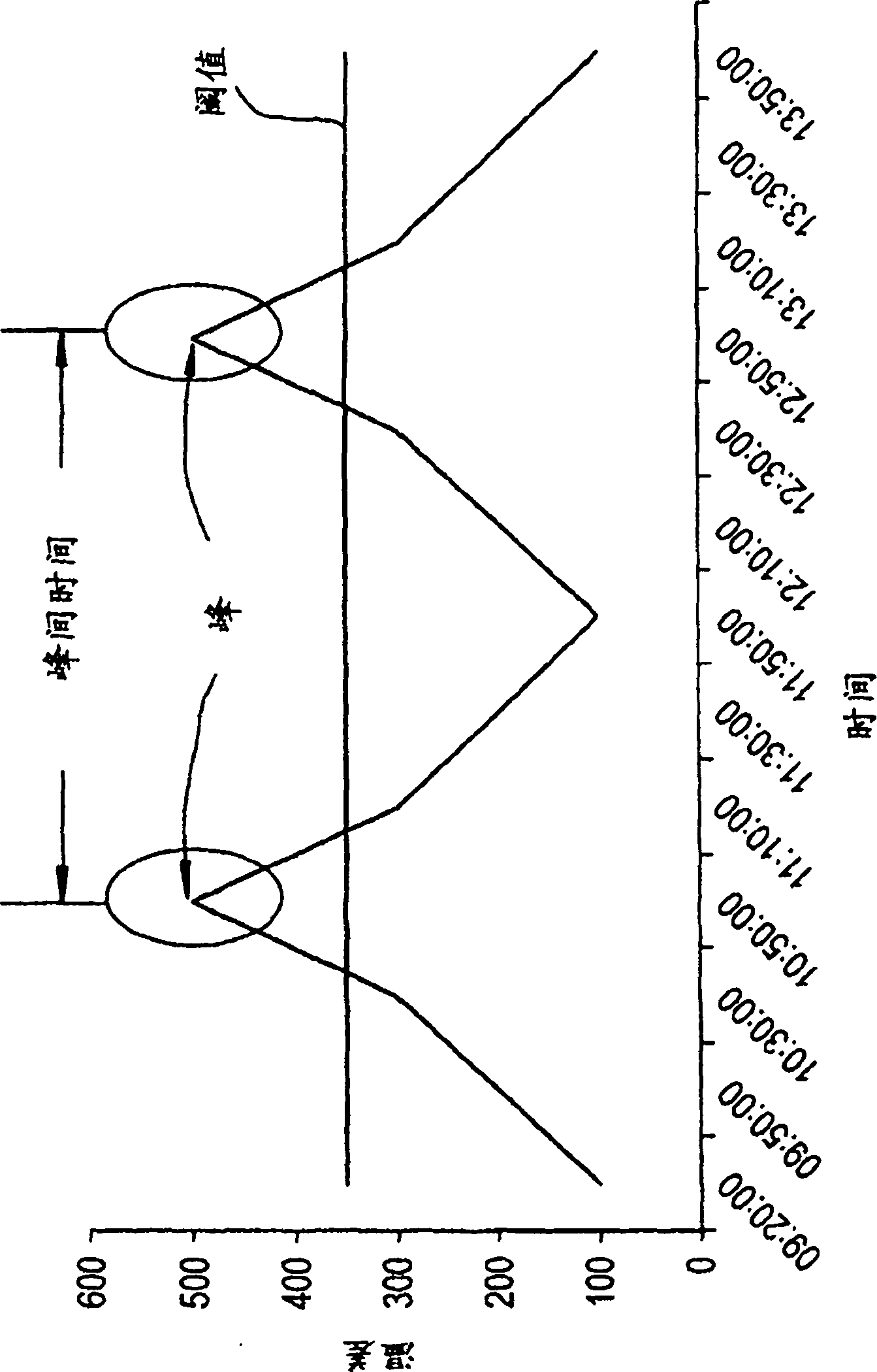

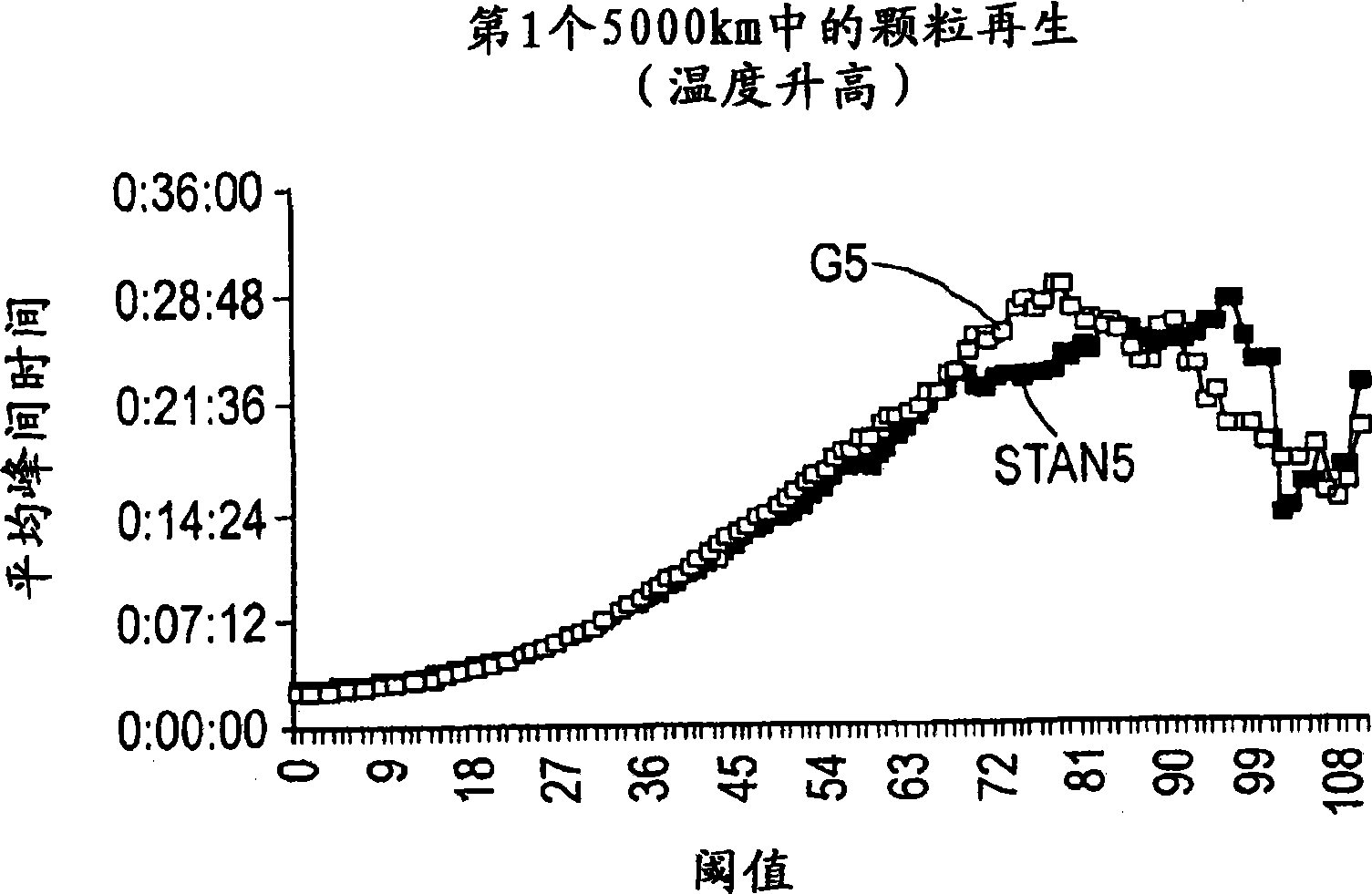

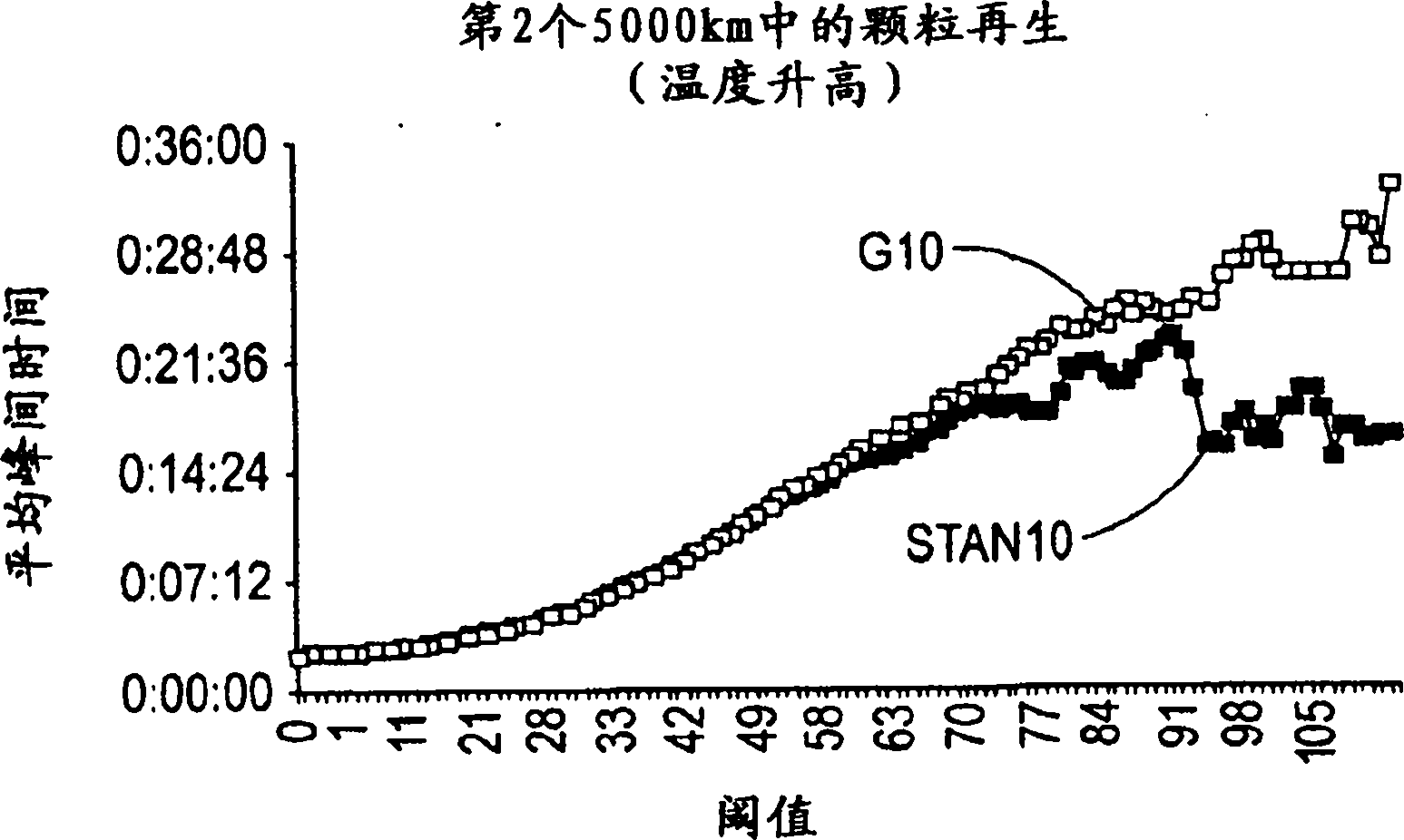

[0060] In experiments using back-to-back tests, a pair of Mercedes C class passenger cars powered by Euro 4 diesel engines were blended with a GTL base oil (Oil A) or a mineral hydrogenated wax (hydrowax) based Group III base oil (Oil B) A comparable 5W-40 engine crankcase lubricant formulation runs. Each vehicle was run with the lubricant in an A-B-A or B-A-B sequence to allow for varying effects between vehicles. The DPT is monitored by a pair of thermocouples upstream and downstream of the DPT.

[0061] DPT regeneration frequency is monitored by temperature differential peaks across the DPT and back pressure peaks in the exhaust system. The trap regeneration frequency is continuously monitored with a data logger throughout the 10,000 mile oil change interval (ODI).

[0062] fuel composition

[0063] Two automotive gas oil compositions were prepared: a Fischer-Tropsch automotive gas oil (F-T AGO) blend consisting of base fuel (S040990) with 250 mg / kg of R655 lubricity p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| loose density | aaaaa | aaaaa |

| loose density | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com