Online low-pressure, middle-pressure and high-pressure combined two-dimension preparation liquid chromatographic system

A technology for two-dimensional preparation and preparation of liquid phase, applied in the field of preparative liquid chromatography system, can solve the problems of high production cost, waste of solvent, complicated and time-consuming and laborious operation, etc., and achieve the effects of saving time, simple operation and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

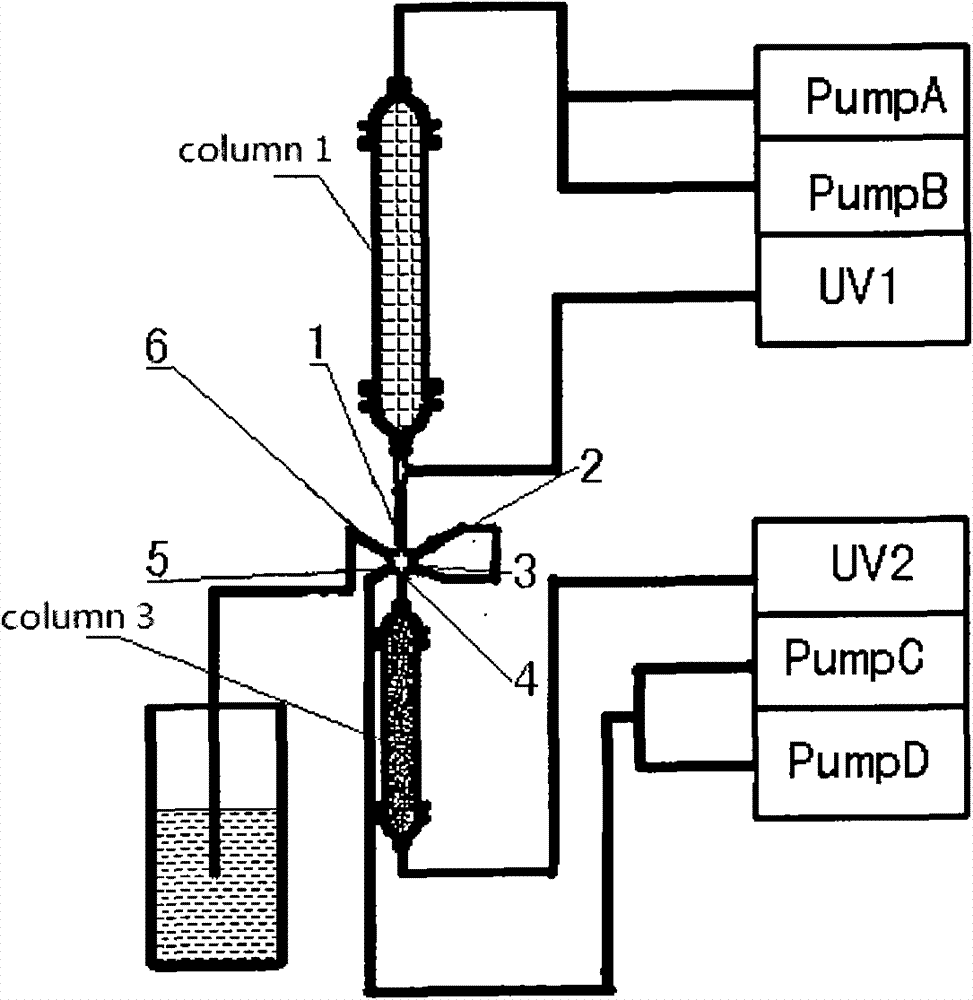

[0023] as attached figure 1 As shown, a two-dimensional preparative liquid chromatography system with online low, medium and high pressure is composed of two low-pressure separation systems and a six-way valve connecting the two separation systems. The No. 1 position of the six-way valve is connected to the No. The outlet of the one-dimensional chromatographic column (column 1) is connected to the detector UV1, the No. 4 position is connected to the inlet of the second-dimensional chromatographic column (column 3), and the No. 5 position is connected to the second-dimensional infusion pump (Pump C, Pump D) , No. 2 and No. 3 positions are connected through external pipelines, and No. 6 position is connected with an external waste liquid collection device.

[0024] In the initial state, six-way valves 1 and 6, 2 and 3, and 4 and 5 are connected, the sample enters the first-dimensional chromatographic column (column 1), and pump A (Pump A) and pump B (Pump B) transport the first-...

Embodiment 2

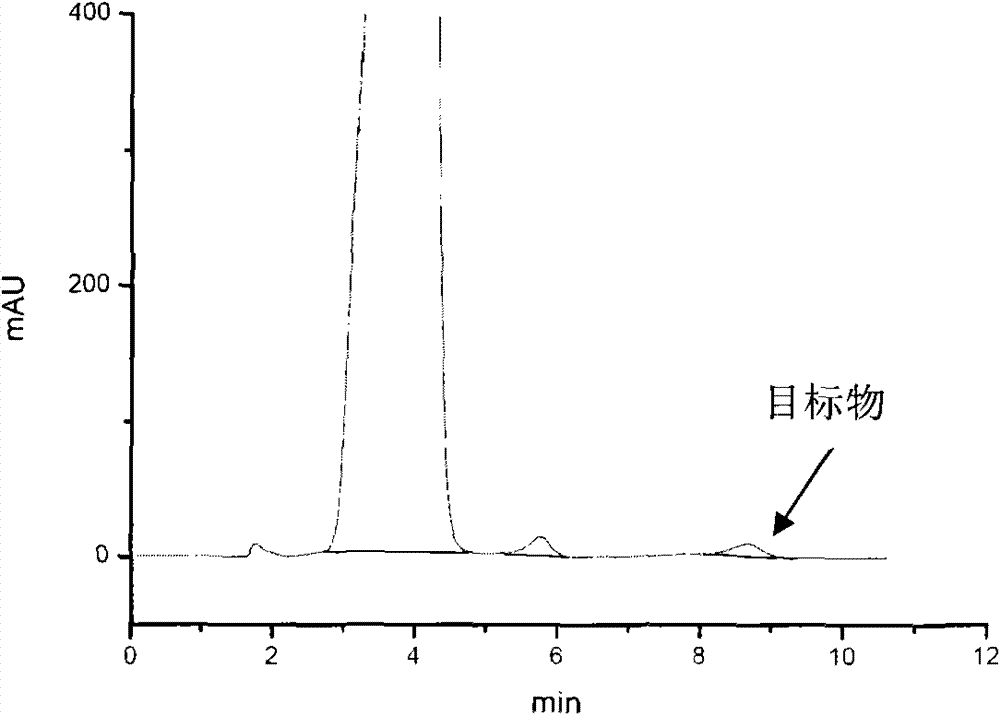

[0026] Please see attached Figure 2-5 , sample: Florfenicol, the target substance is one of the low-level impurities, and the original HPLC analysis chromatogram is as follows figure 2 shown.

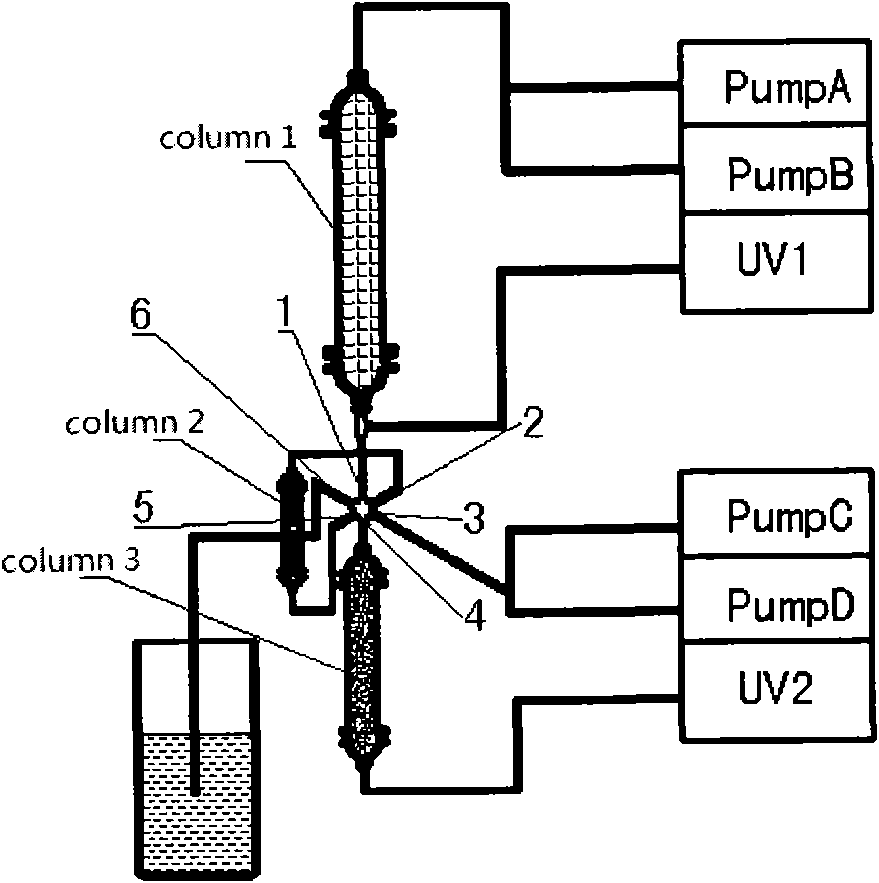

[0027] System composition: an online low and high pressure mixed two-dimensional preparative liquid chromatography system, column 1 is a 30mm×300mm glass chromatographic column filled with 50μm C18 filler; column 2 is a 5mm×50mm stainless steel chromatographic column with a 30μm filler C18 chromatographic stationary phase; column 3 is a 10mm×250mm stainless steel chromatographic column filled with 5μm C18 filler. Both UV1 and UV2 are dual-wavelength ultraviolet detectors.

[0028] Chromatographic conditions: the detection wavelength is 225nm, 230nm. Both the first and second dimension chromatographic systems use water and methanol as mobile phases, and gradient elution.

[0029] Refer to attached Figure 4 , which is the second-dimensional chromatogram obtained by using the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com