Multi-functional soft contact lens mould

A soft contact lens, multi-functional technology, applied to other household appliances, optical components, household appliances, etc., can solve the problem of wasting molds, etc., and achieve the effects of low injection molding cost, simple hydration operation, and stable injection molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The concrete implementation of the present invention is realized in the following manner, and the implementation of the mold structure design of this kind of production soft contact lens follows the following steps successively: the design and processing of metal mold core, the injection molding of plastic mold, the curing molding of lens, lens Hydration, lens encapsulation.

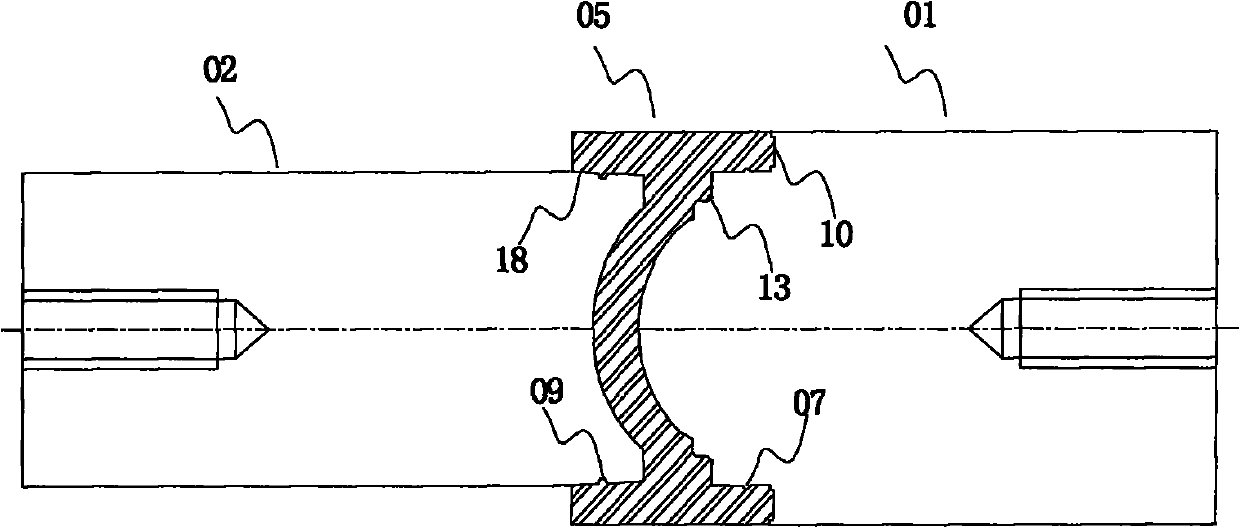

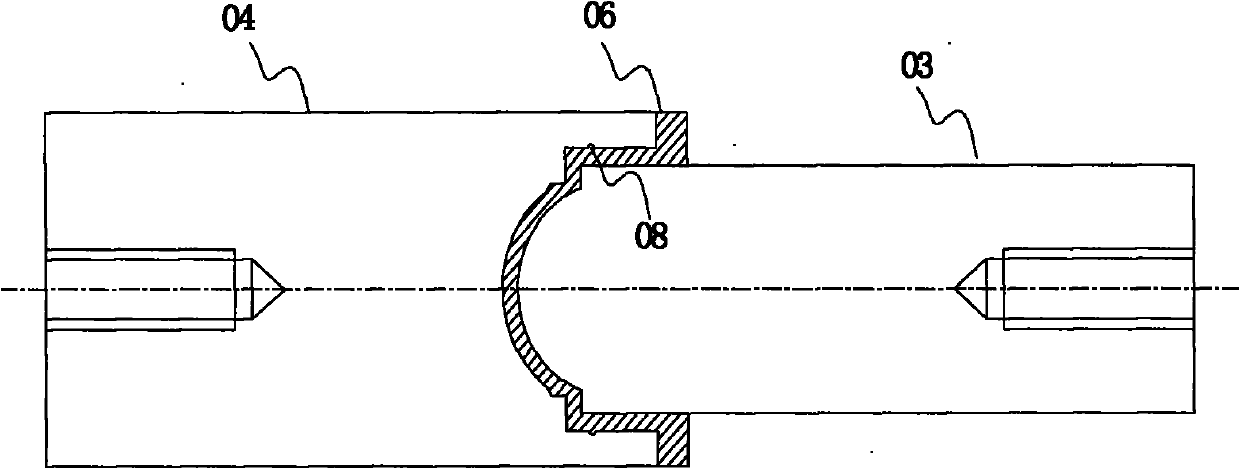

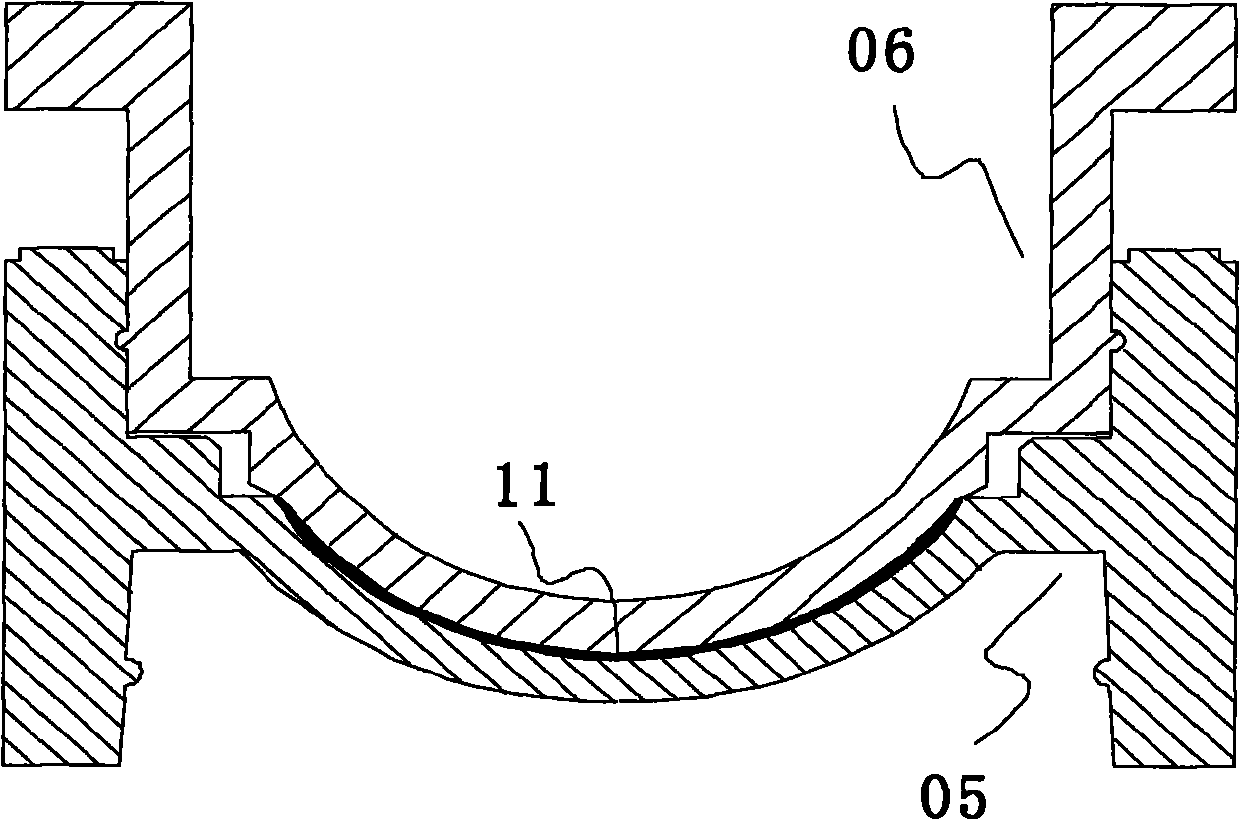

[0025] 1. Design and processing of the metal mold core: design the metal front mold core 01 of the lower mold with optical functions (attached figure 1 ) and the metal rear mold core 02 of the lower mold without optical function (attached figure 1 ); the upper mold metal rear mold kernel 04 with optical function (attached figure 2 ) and the upper mold metal front mold core 03 without optical function (attached figure 2 ). A concave ring 08 is also designed on the metal rear mold core 04 column wall of the upper mold, as a positioning ring for the lower mold, the ring is concave 0.15mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Chamfer angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com