Grey leather pulling device for splitting machine

A technology of gray skin and split layer, which is applied in raw hide/leather/fur manufacturing equipment, small raw hide/big raw hide/leather/fur treatment, leather manufacturing, etc. It can solve problems such as high labor intensity, waste of manpower, and low work efficiency , to achieve the effect of reducing labor intensity, improving work efficiency and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

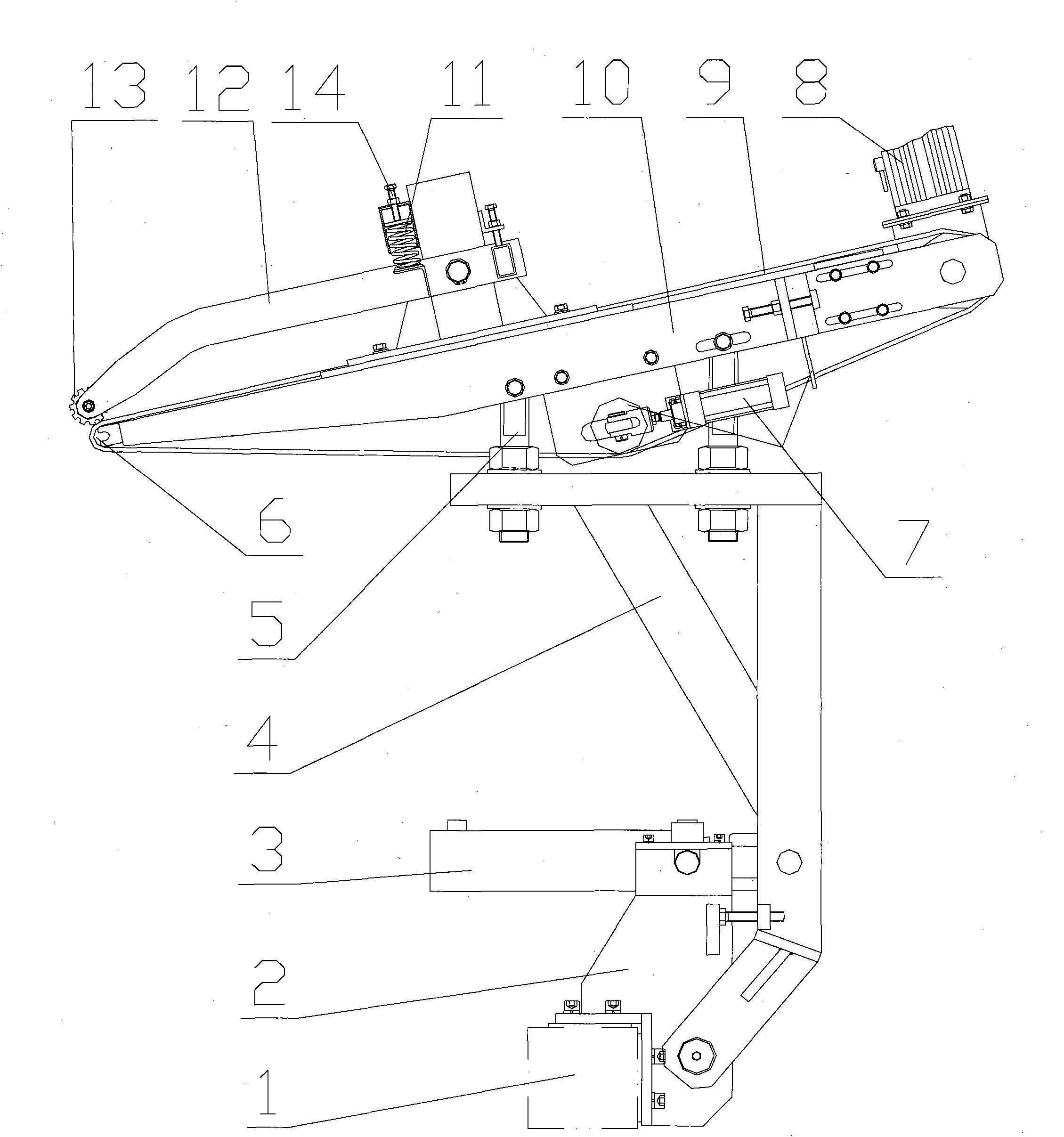

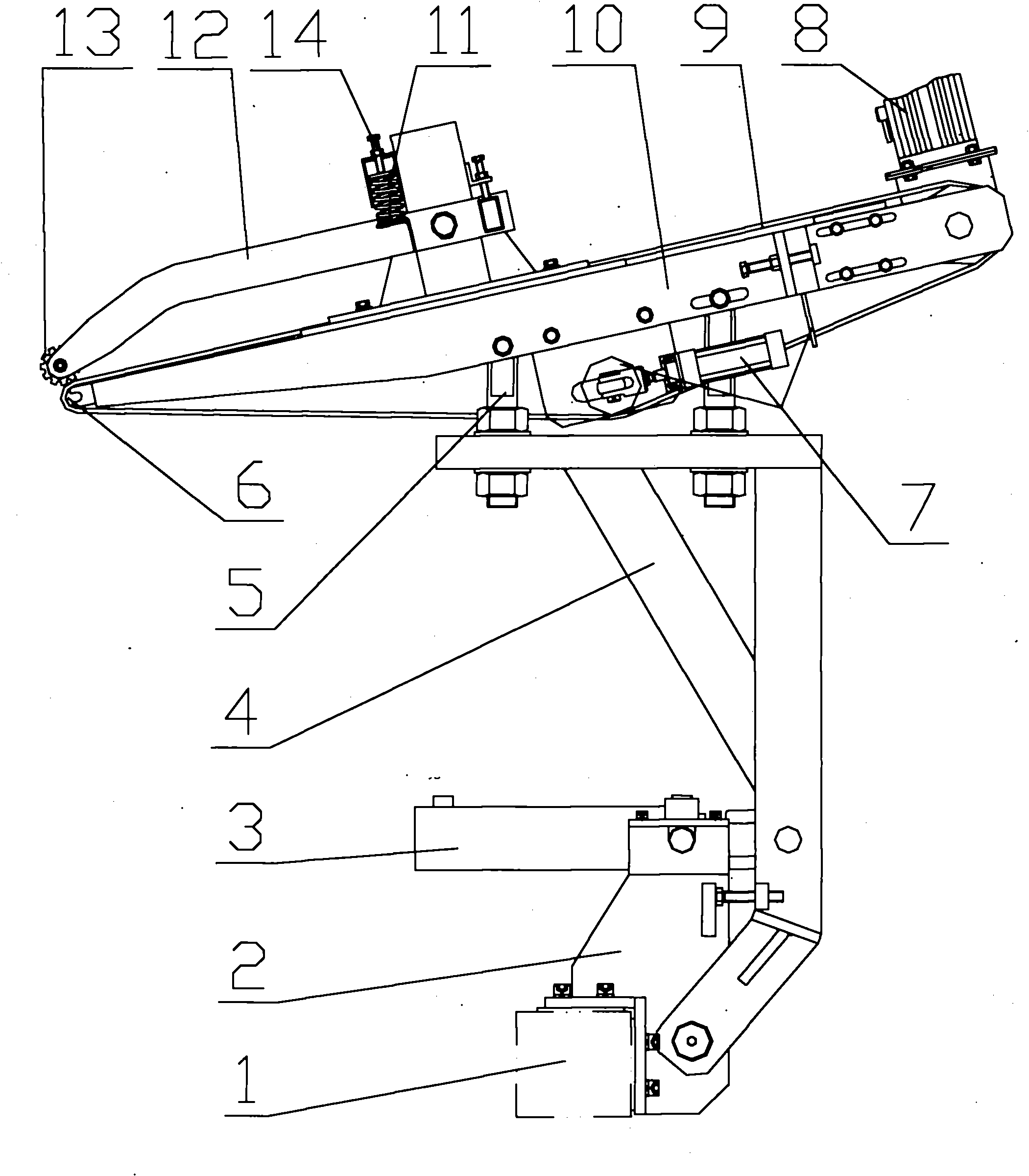

[0015] Such as figure 1 As shown, the gray skin lifting device of the splitting machine includes a support adjustment part, a transport frame 10, a leather pressing frame 12, and a reducer 8. The transport frame 10 is installed on the support position adjustment part, and the transport frame 10 is provided with For the conveyor belt 9 connected with the speed reducer 8, one end of the leather pressing frame 12 is pressed by a spring 11, and the other end is provided with a plurality of pressing rollers 13, and the pressing rollers 13 are arranged close to the conveying belt 9. The front end of the conveyor frame is provided with a conveyor roller 6, and the pinch roller 13 of the leather press frame 12 and the front conveyor roller 6 of the conveyor frame 10 stretch into the splitter as far as possible. The support position adjustment part includes a base 2, an oil cylinder 3 arranged on the base 2, a rocker frame 4 connected to the oil cylinder 3, and several support rods 5, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap