Aircraft aero-servo-elasticity ground simulating test system

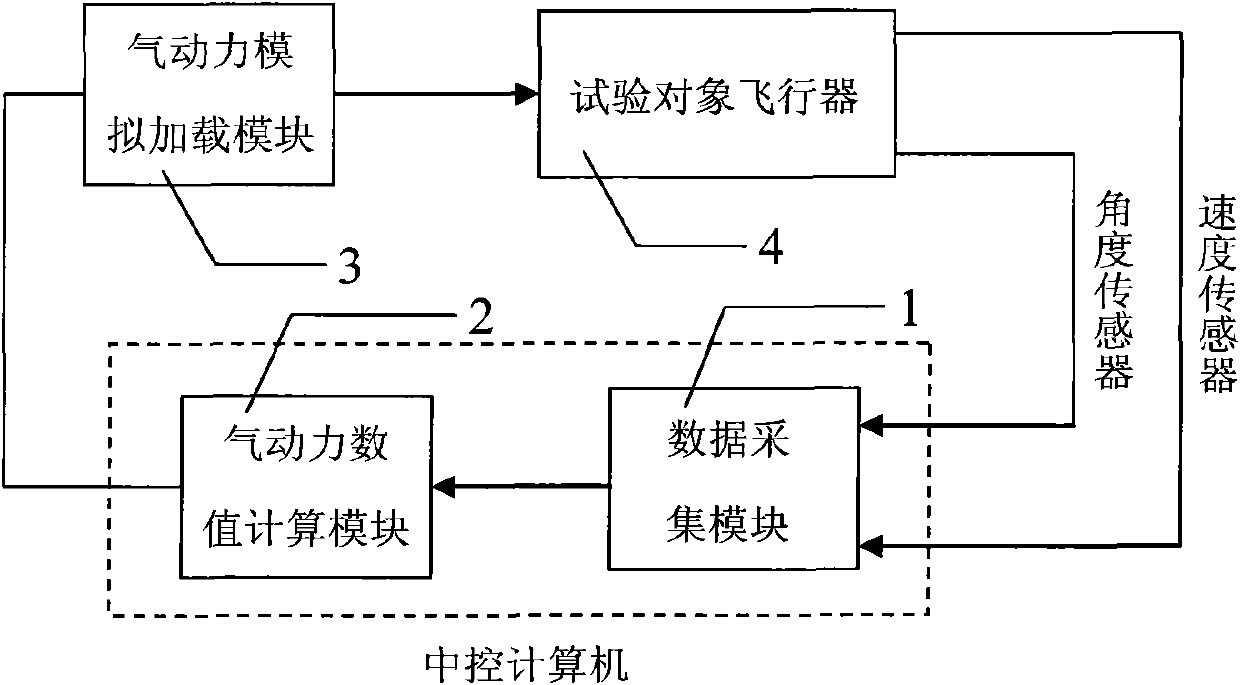

A technology of servo elasticity and ground simulation, applied in aerodynamic tests, machine/structural component testing, instruments, etc., can solve problems such as difficulty in considering various nonlinear factors, aircraft aerodynamic servo elasticity, and aircraft stability degradation, etc. Achieve the effect of good versatility and scalability, scientific and reasonable principles, and easy comparative research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

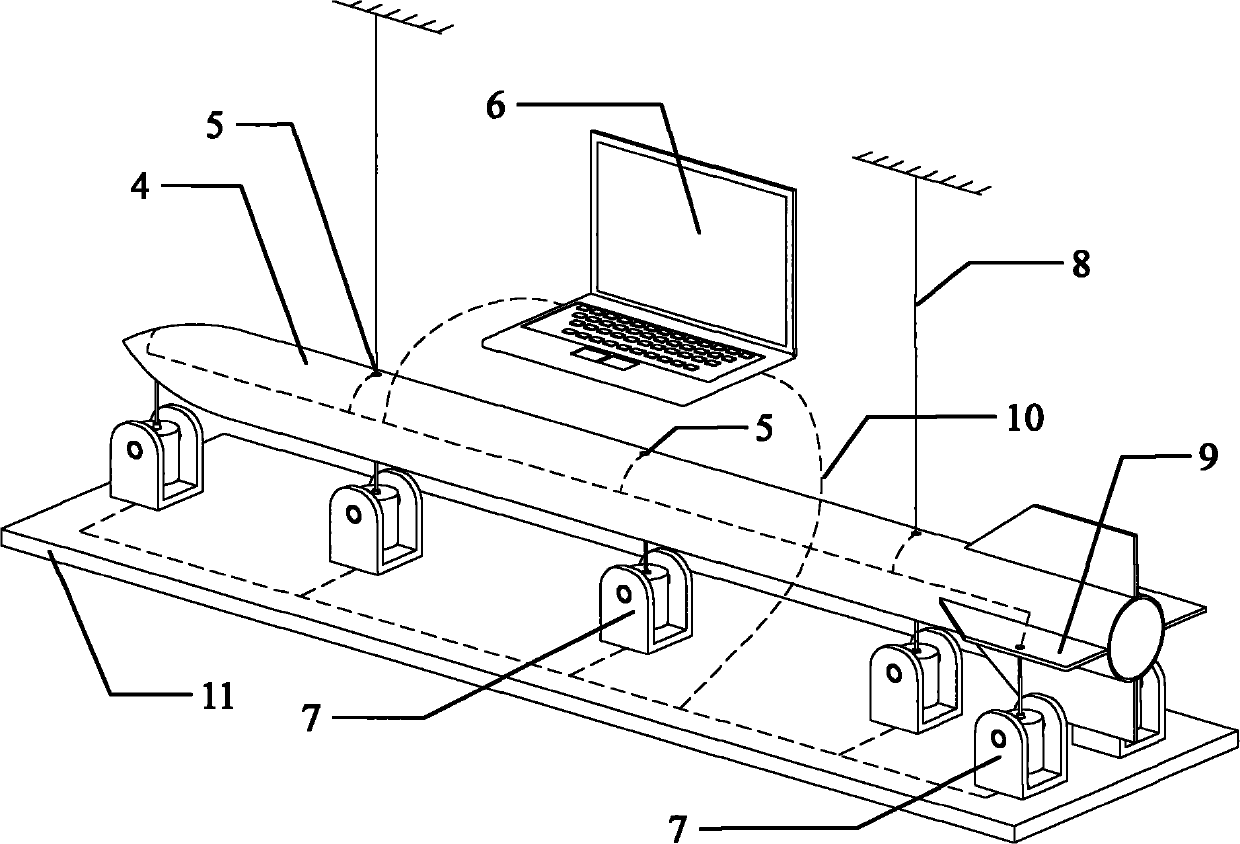

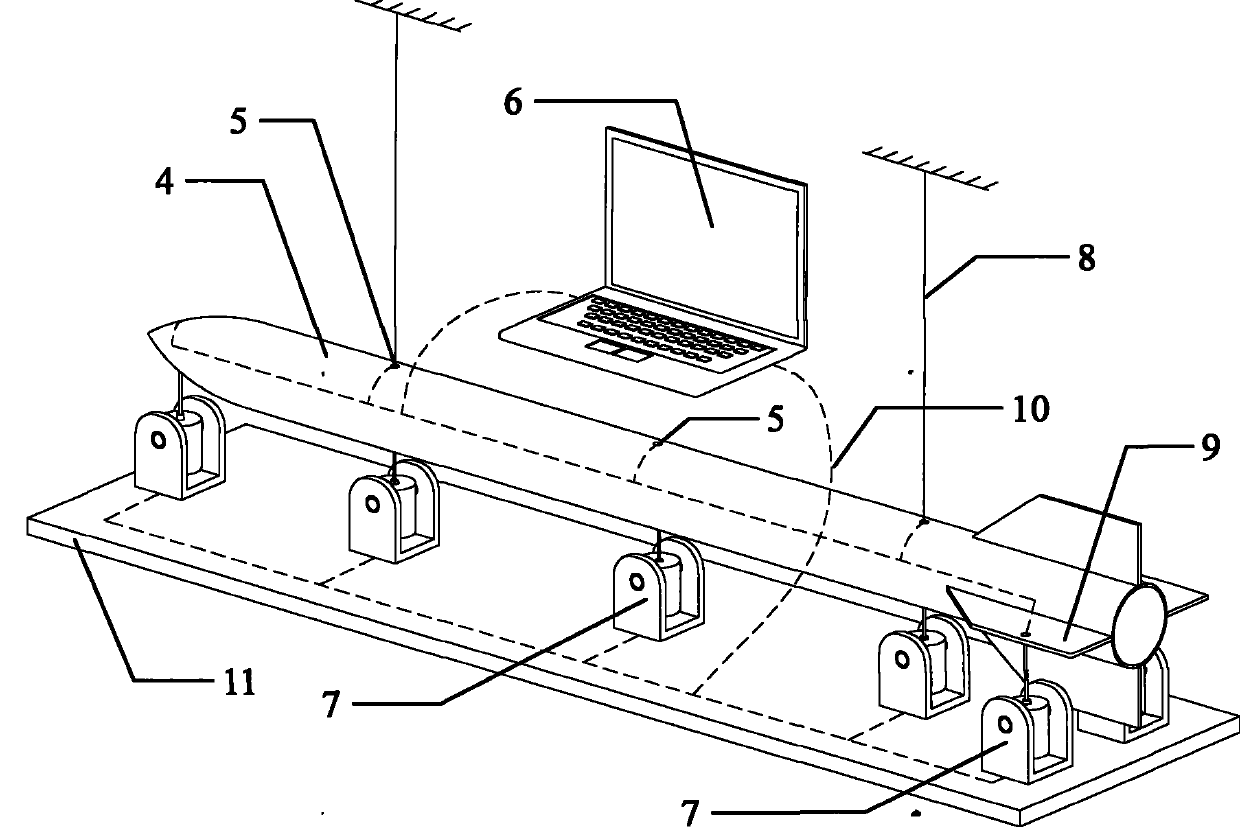

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as figure 2 Shown is the hardware arrangement of an embodiment of the present invention, and the test object is such as a slender and slender body missile, and the 4 control rudder surfaces at the tail of the missile body are distributed in a "+" shape, and the rudder surface steering gear is controlled by the flight control stabilization system. drive. Because the projectile body is slender and flexible, the angular rate gyroscope or overload sensor used as the input signal of the missile control and stabilization system not only senses the rigid body motion signal of the missile, but also senses the structural vibration signal of the aircraft, which may cause additional rudder surface vibration. High-frequency vibrations lead to a decrease in the stability of the control and stabilization system origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com