Anisotropy composite material workpiece tool template design method of autoclave molding composite material

A tooling design and anisotropic technology, applied in computing, special data processing applications, instruments, etc., can solve the problem that the anisotropic composite material parts and the anisotropic thermal expansion coefficient of the tooling template are difficult to match

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

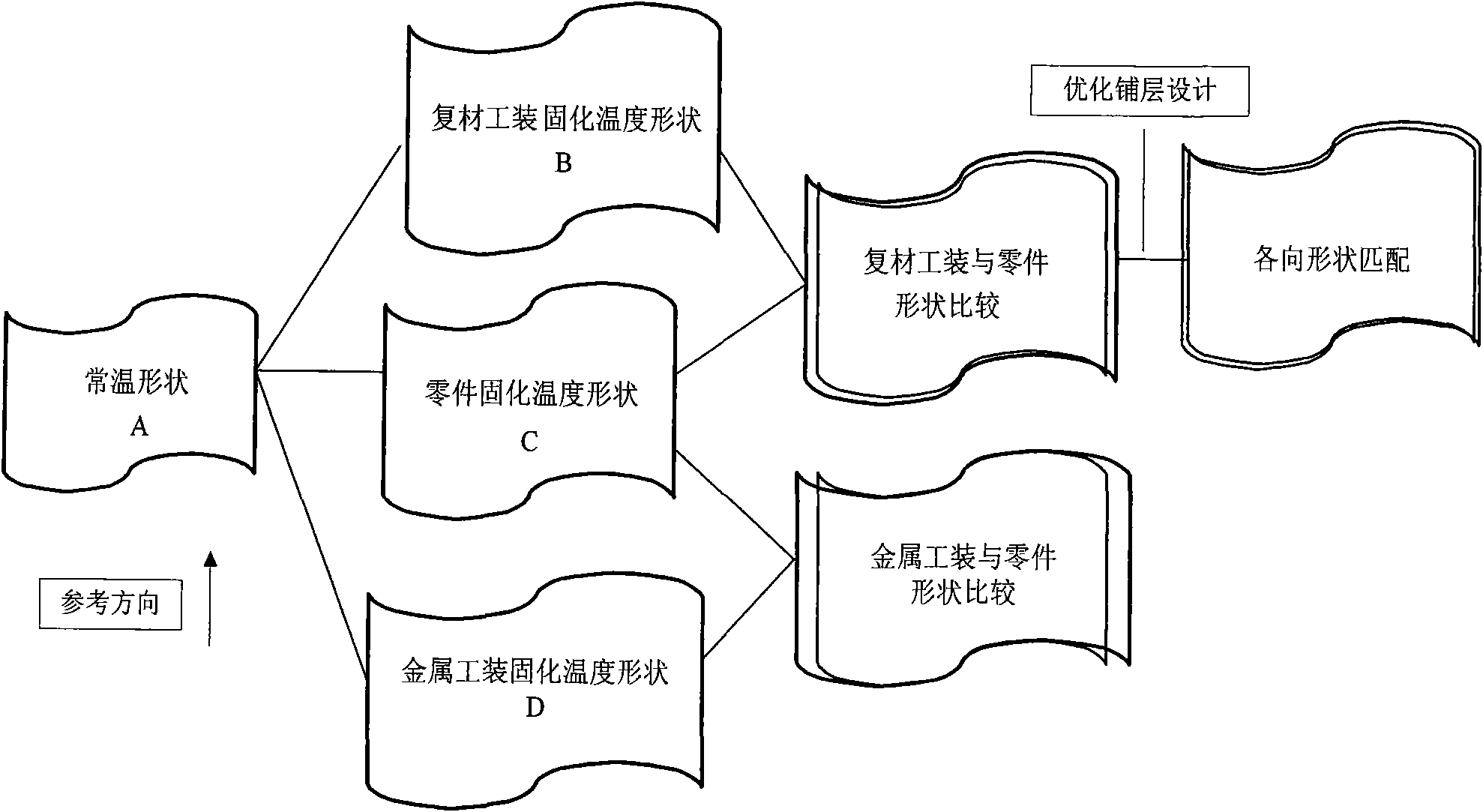

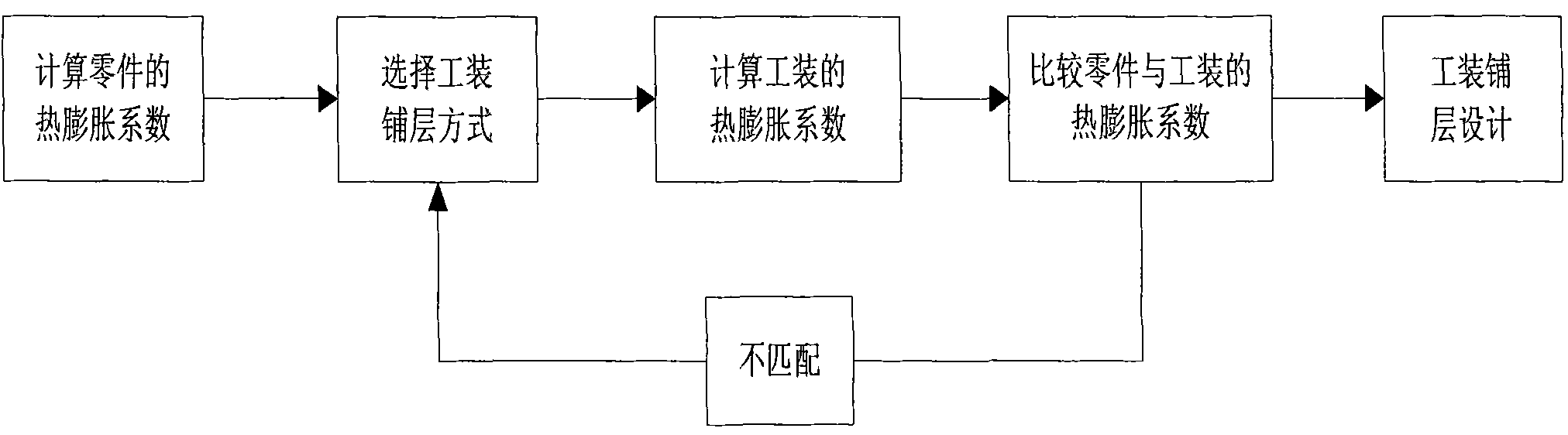

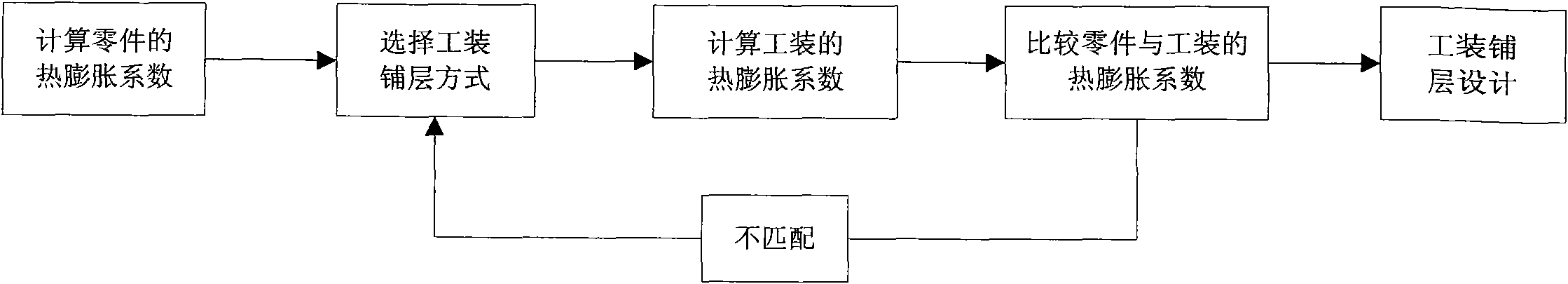

[0050] Composite materials used for low-temperature forming and high-temperature use are used as tooling formwork materials. Based on the lay-up information of anisotropic composite material parts, the calculation formula of thermal expansion coefficient in the scheme is used to calculate the anisotropic composite material parts in all directions. The thermal expansion coefficient of the composite tooling formwork is designed based on this, and then the thermal expansion coefficient of the tooling is calculated. Through the comparison of the thermal expansion coefficients of the parts and the tooling, the design of the tooling formwork is optimized, and finally the tooling and tooling are compared. The coefficient of thermal expansion of the part is matched in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com