Cutting tool

A cutting tool and cutting body technology, applied in the direction of manufacturing tools, tool-workpiece connection, turning equipment, etc., can solve the problems of large structural space, weakening the tool matrix, etc., and achieve the effect of high functional safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

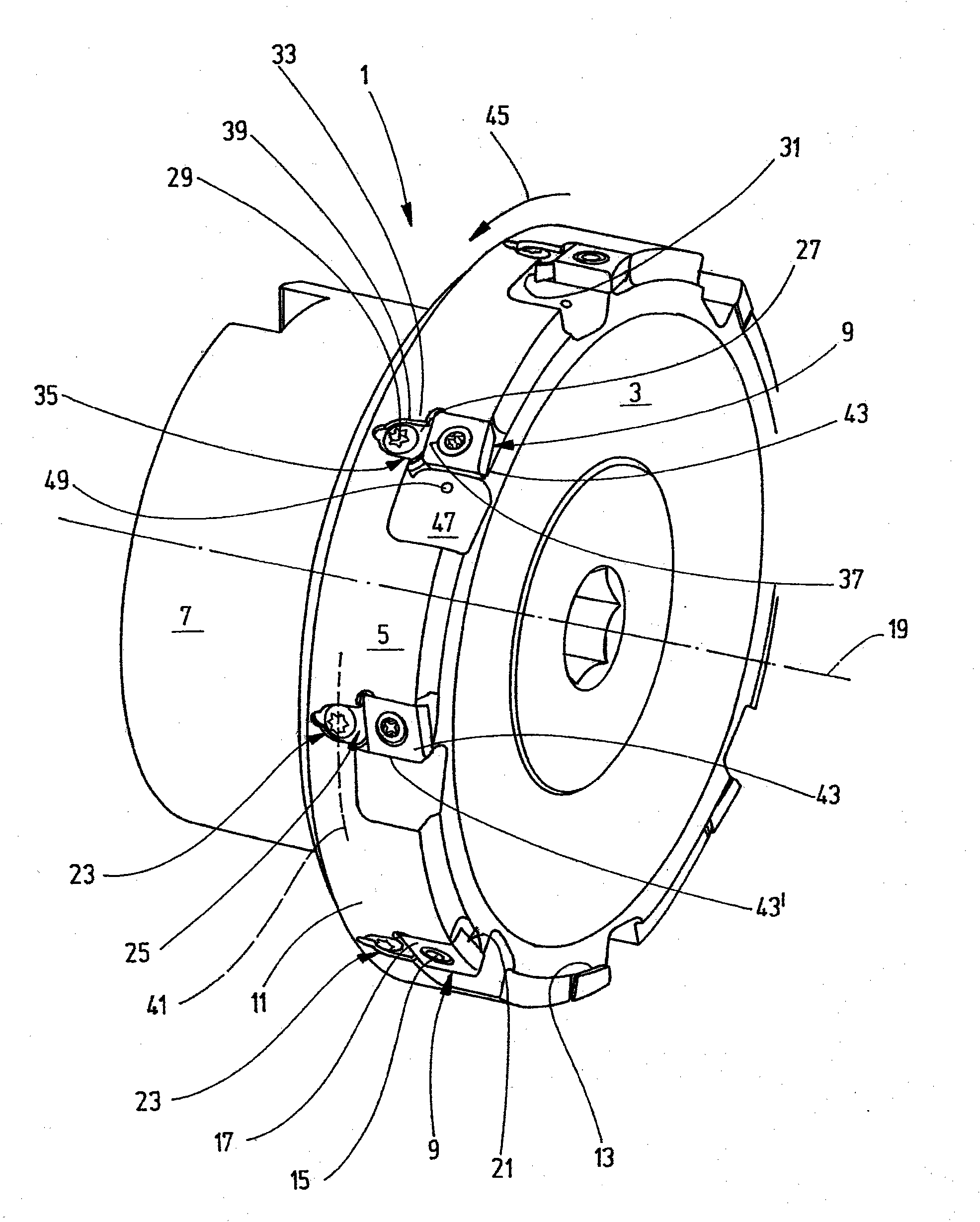

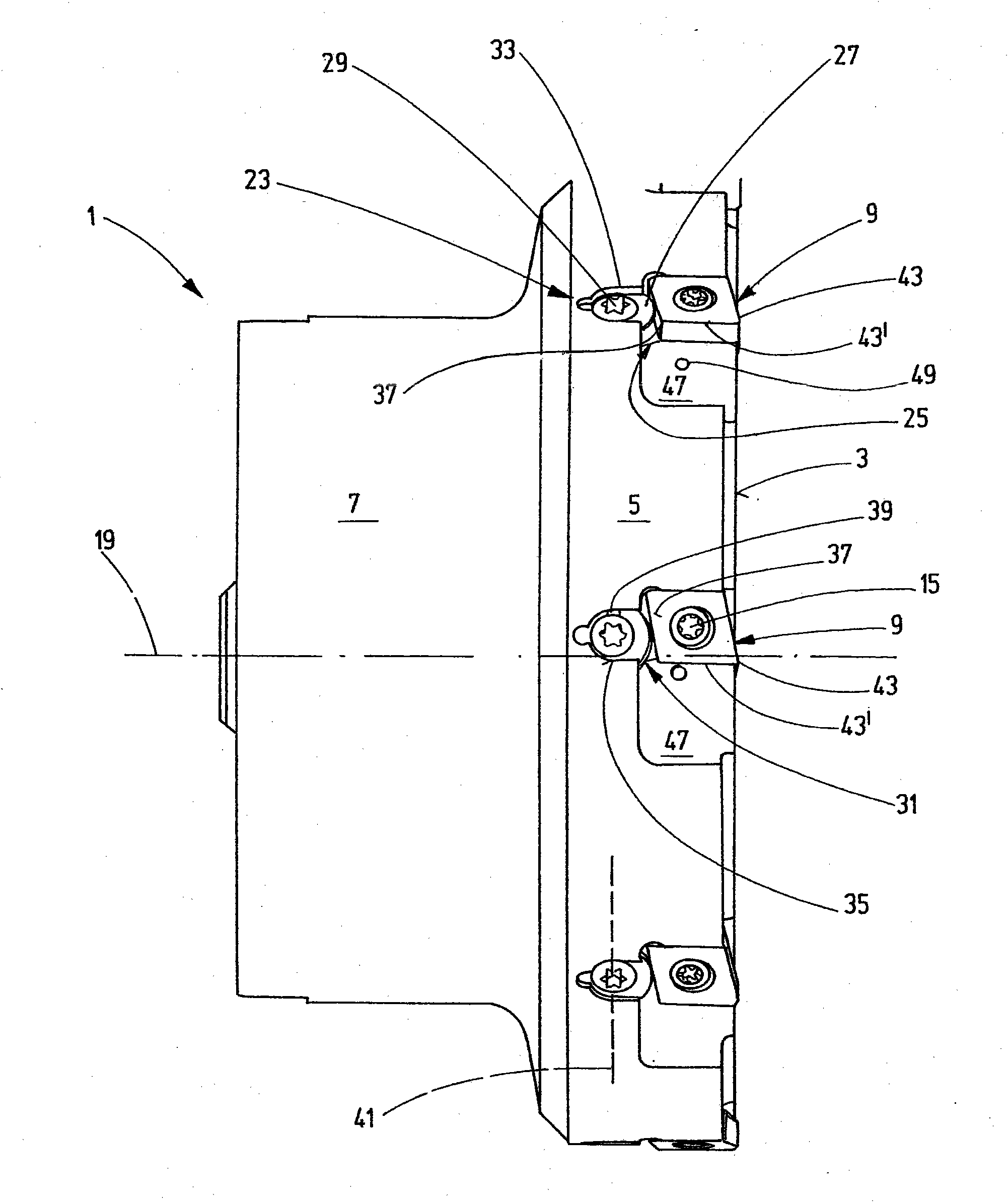

[0013] figure 1 The cutting tool 1 illustrated in is configured as a face milling cutter, for example. The cutting tool 1 is shown in a perspective view, so that, outside its circumferential surface, its front side is also visible. The cutting tool, referred to below simply as tool 1 , has a shank 7 for connecting the tool to the machine tool directly or via intermediate blocks, adapters or the like.

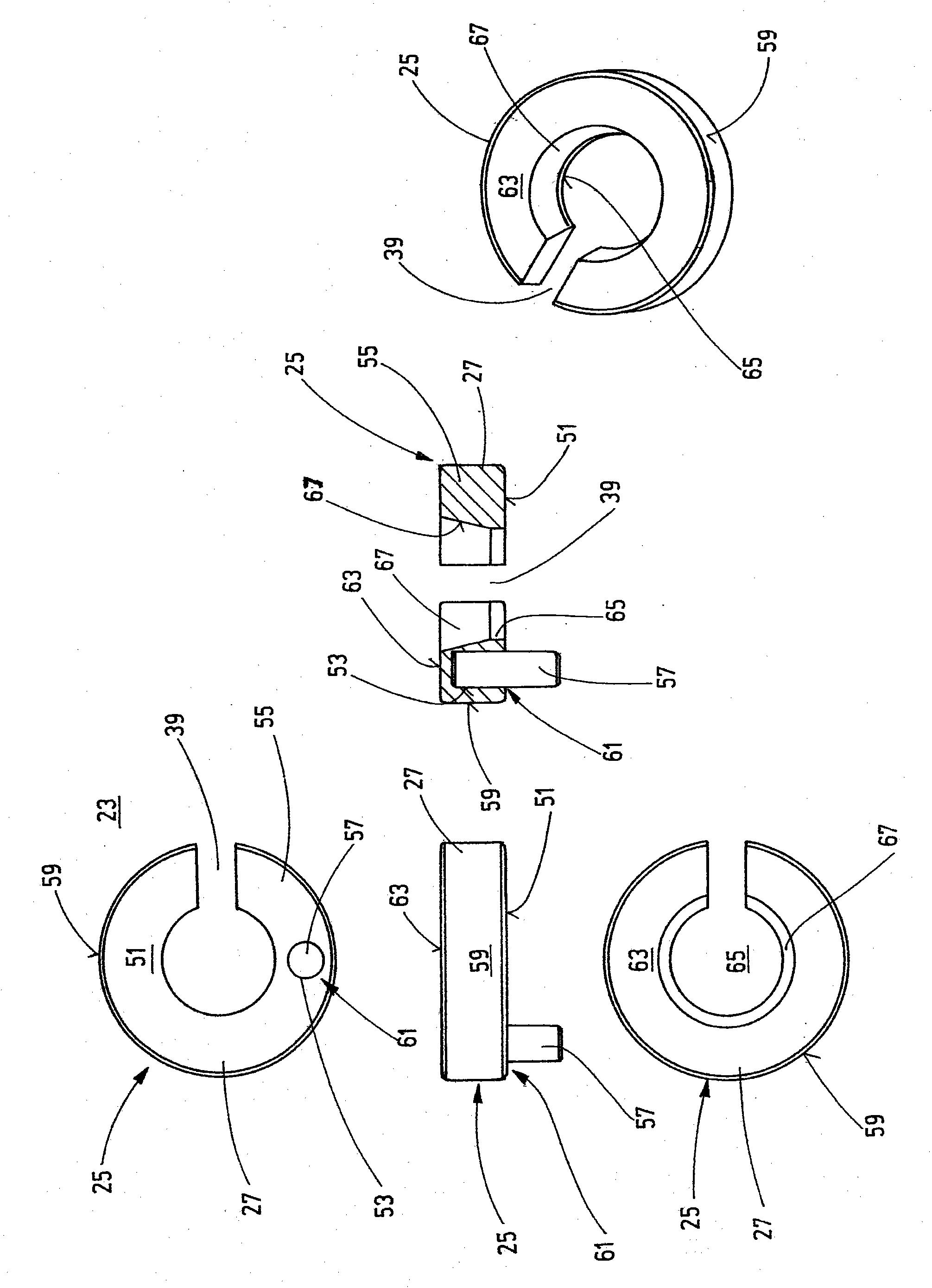

[0014] The tool 1 has at least one cutting body, here configured as a cutting disc 9 . The exemplary embodiment shown here provides eight such cutter heads 9 which are fastened to the base body 11 of the tool 1 . Here, the cutter head is mounted in the inclined recess 13 and fixed tangentially to the tool 1 by means of fastening screws 15 . The fastening screw 15 passes vertically through the cutter head. That is to say, the axis of rotation of the fastening screw 15 , not shown here, is perpendicular to the center axis 19 of the tool 1 , which also illustrates the axis of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com