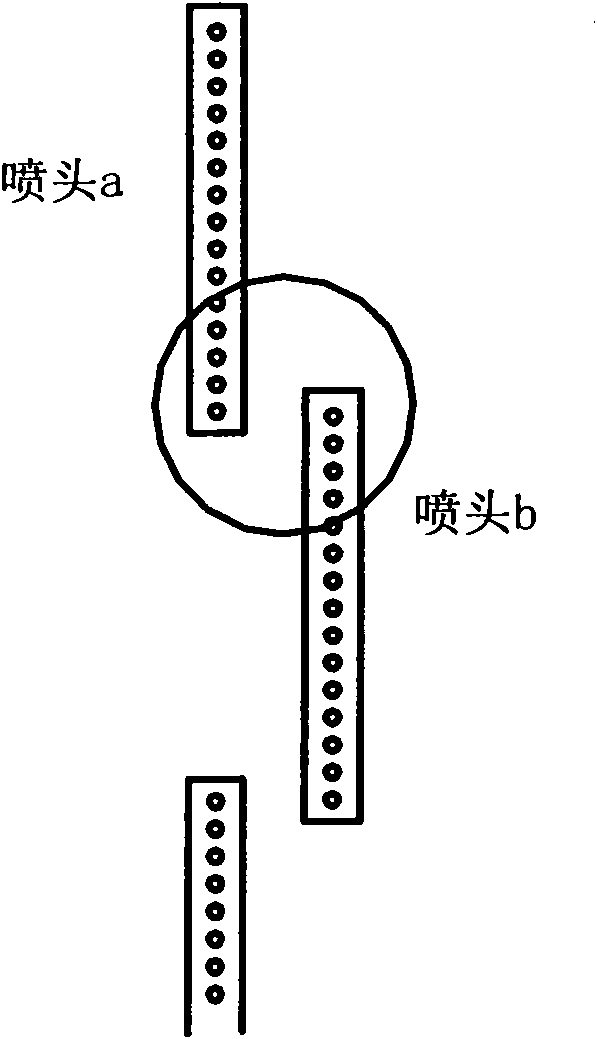

Method for processing overlapped positioning error of splicing spray heads

A processing method and technology of positioning error, applied in printing and other directions, can solve the problems of small printing range of nozzles and large errors of nozzle head and tail splicing, and achieve the effect of simple, accurate and reliable method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

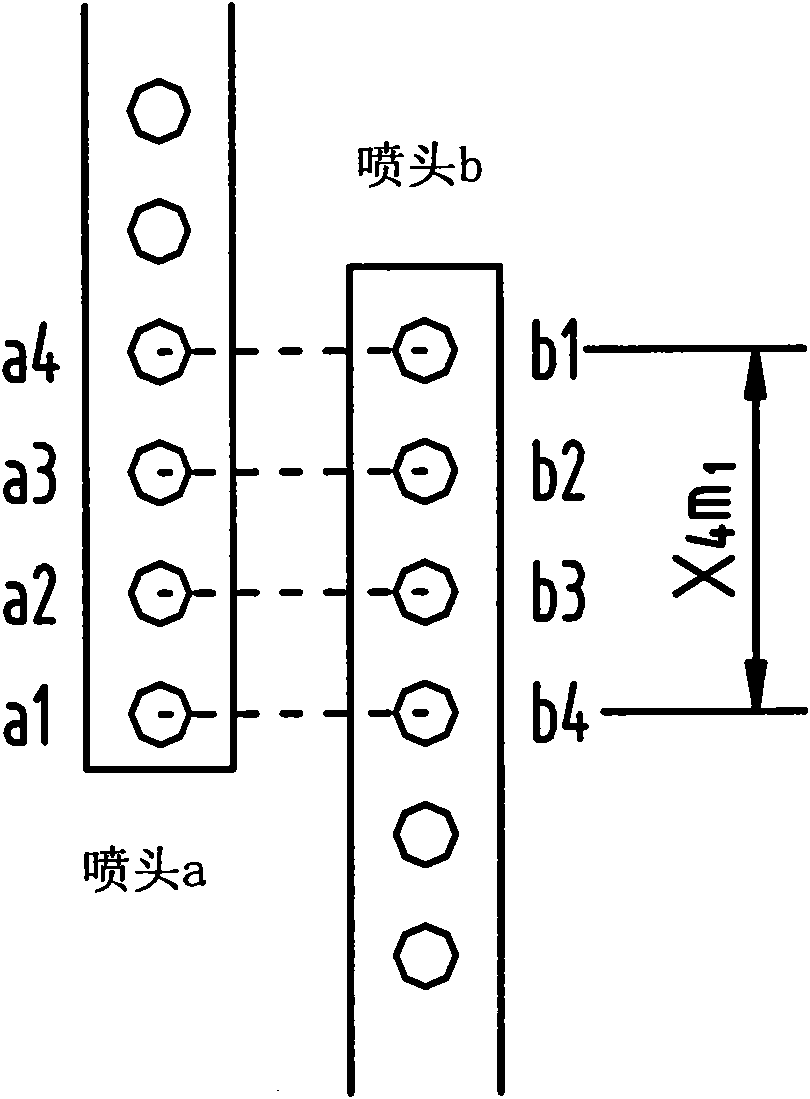

Embodiment 1

[0029] Embodiment 1: deep and shallow feathering processing: (such as Figure 2A shown), you can set:

[0030] Measured to get X4 1 =X4 0 ;

[0031] a1=20%, b1=20%;

[0032] a2=40%, b2=40%;

[0033] a3=60%, b3=60%;

[0034] a4=80%, b4=80%;

[0035] Then a1+b4=100%;

[0036] a2+b3=100%;

[0037] a3+b2=100%;

[0038] a4+b1=100%.

[0039] The feathering treatment of the nozzles a and b at the overlap can be realized, so that the final effect is consistent with the effect of the non-overlapping part. This feathering effect can also effectively solve the performance change or blockage of the nozzles caused by the long-term inactivity of some nozzles during the non-eathering process.

[0040] The feathering percentage value can be defined arbitrarily or generated randomly, but it needs to meet the requirement of consistent total amount.

Embodiment 2

[0041] Embodiment 2 (as Figure 2C shown): Total compensation method.

[0042] Measured to get X4 3 >X4 0 ,

[0043] Then the total amount should increase: X4 3 / X4 0 , then both a1-a4 and b1-b4 should be increased by X4 3 / X4 0 amount.

[0044] Such as: X4 3 / X4 0 = 112.5%,

[0045] Suppose a1 and b1 differ by half a point

[0046] Then a1=20%*1.125=22.5%;

[0047] a2=40%*1.125=45%;

[0048] a3=60%*1.125=67.5%;

[0049] a4=80%*1.125=90%;

[0050] Then b1-b4 is also similar, and finally the total amount of dots in the X3 area is consistent with the effect of the dots not in this area.

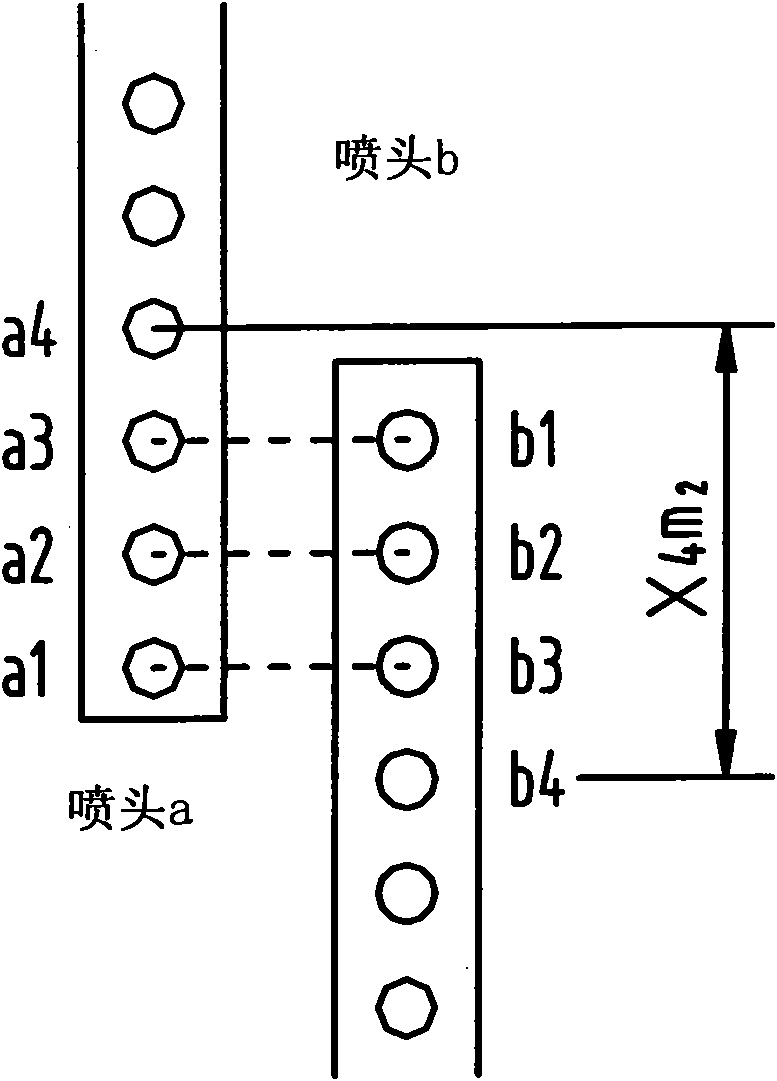

Embodiment 3

[0051] Embodiment 3 (as Figure 2B ):

[0052] The actual measurement results in a complete misalignment of one point, then

[0053] X4 2 / X4 0 = 125%;

[0054] Then a1=20%*1.25=25%;

[0055] a2=40%*1.25=50%;

[0056] a3=60%*1.25=75%;

[0057] a4=80%*1.25=100%;

[0058] Then b1-b4 is also similar, and finally the effect in the X2 area is consistent with the spray point effect in the non-this area. also with Figure 2A The results shown are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com