High impact force resistance gas-bag armor

A technology of impact force and airbags, applied in the direction of bumpers, etc., can solve the problems of weak impact resistance, small bumper installation space, and limited aesthetic factors, and achieve the effect of meeting the strength of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

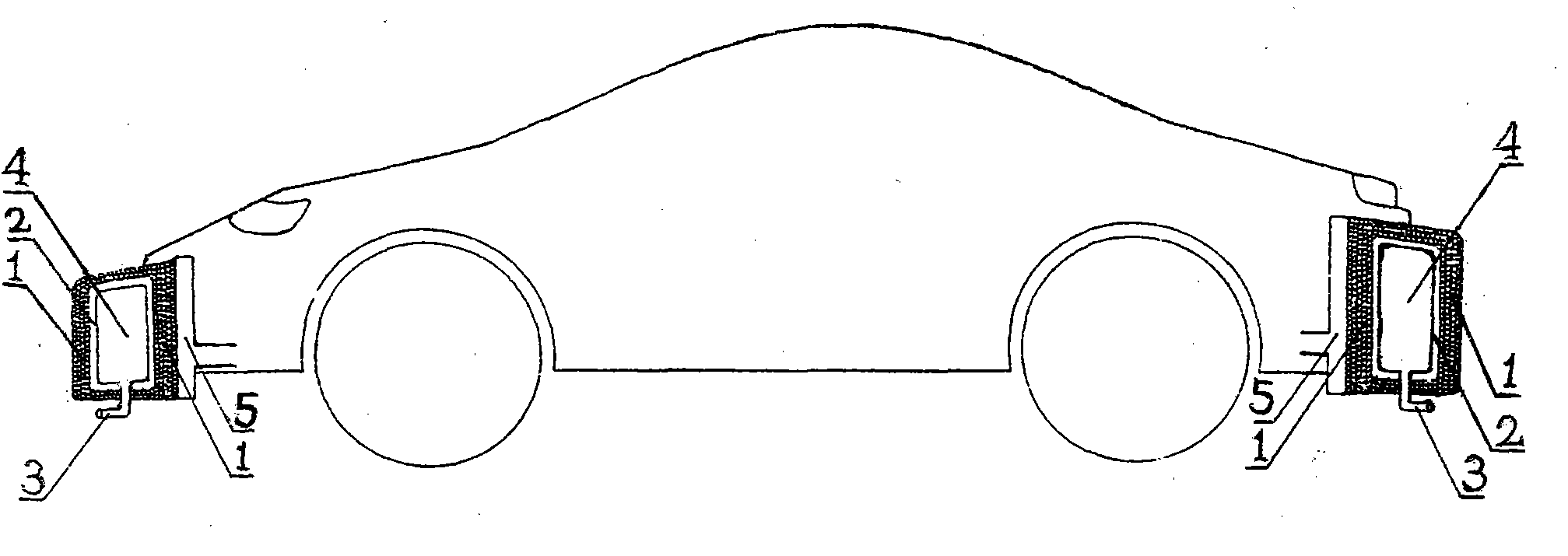

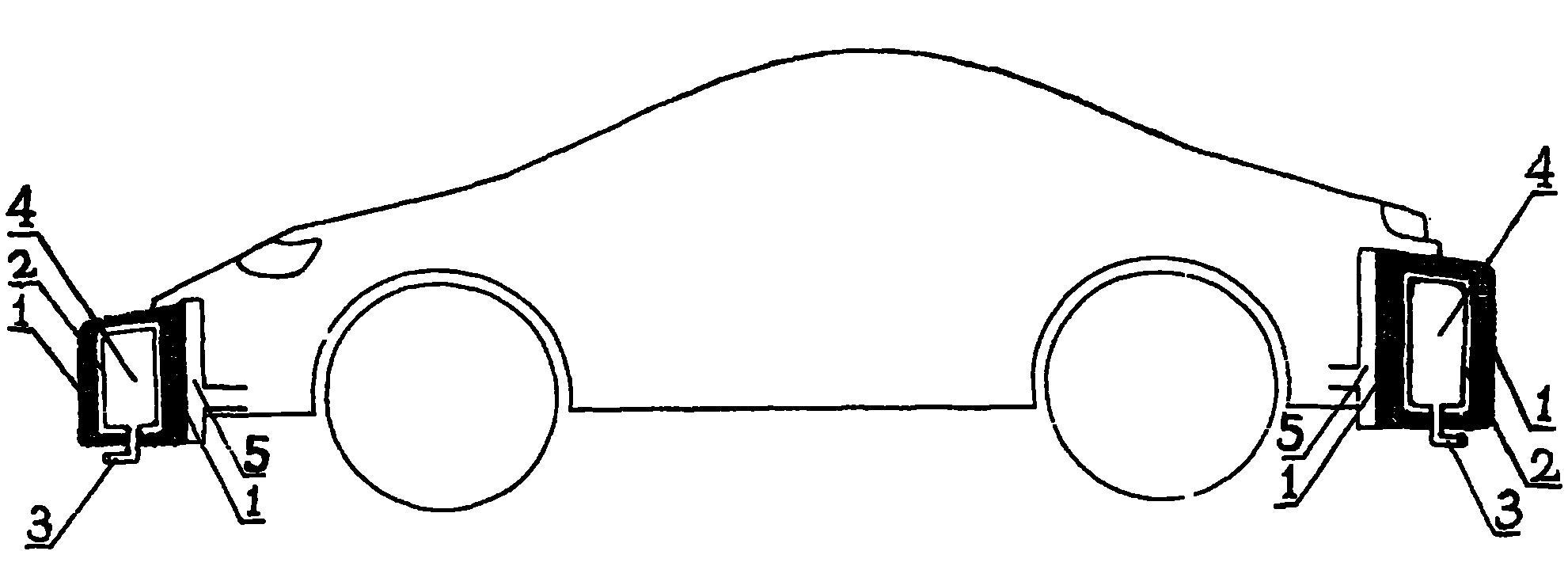

[0013] High-impact airbag armor, which is composed of high-resistance foam plastic (1), elastomer plastic (2), inflation nozzle (3), high-pressure gas (4), and bar beam (5), wherein: the outer layer adopts higher The thickness of the high-resistance foam plastic (1) and the inner layer of elastomeric plastic (2) are closed inwardly to form a cavity, and an inflation nozzle (3) is provided, and the high-pressure gas (4) is filled into the cavity through the inflation nozzle (3) For absorbing impact energy, one end of the high-resistance foamed plastic (1) is connected with the vehicle body through a bar beam (5) and integrated for safety protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com