Wiper blade provided with transferring unit used for fixing on wiper arm

A technology of adapter unit and wiper blade, which is applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of complexity and troublesome operation of the adapter unit, and achieve the effect of simple cost and simple axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

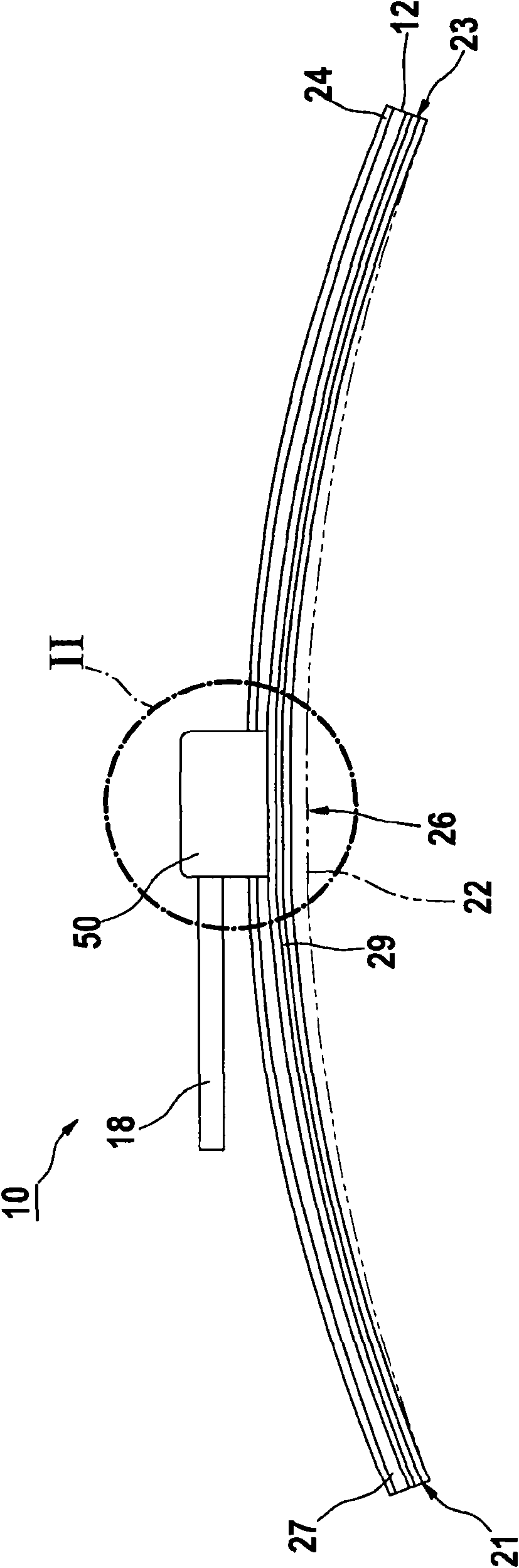

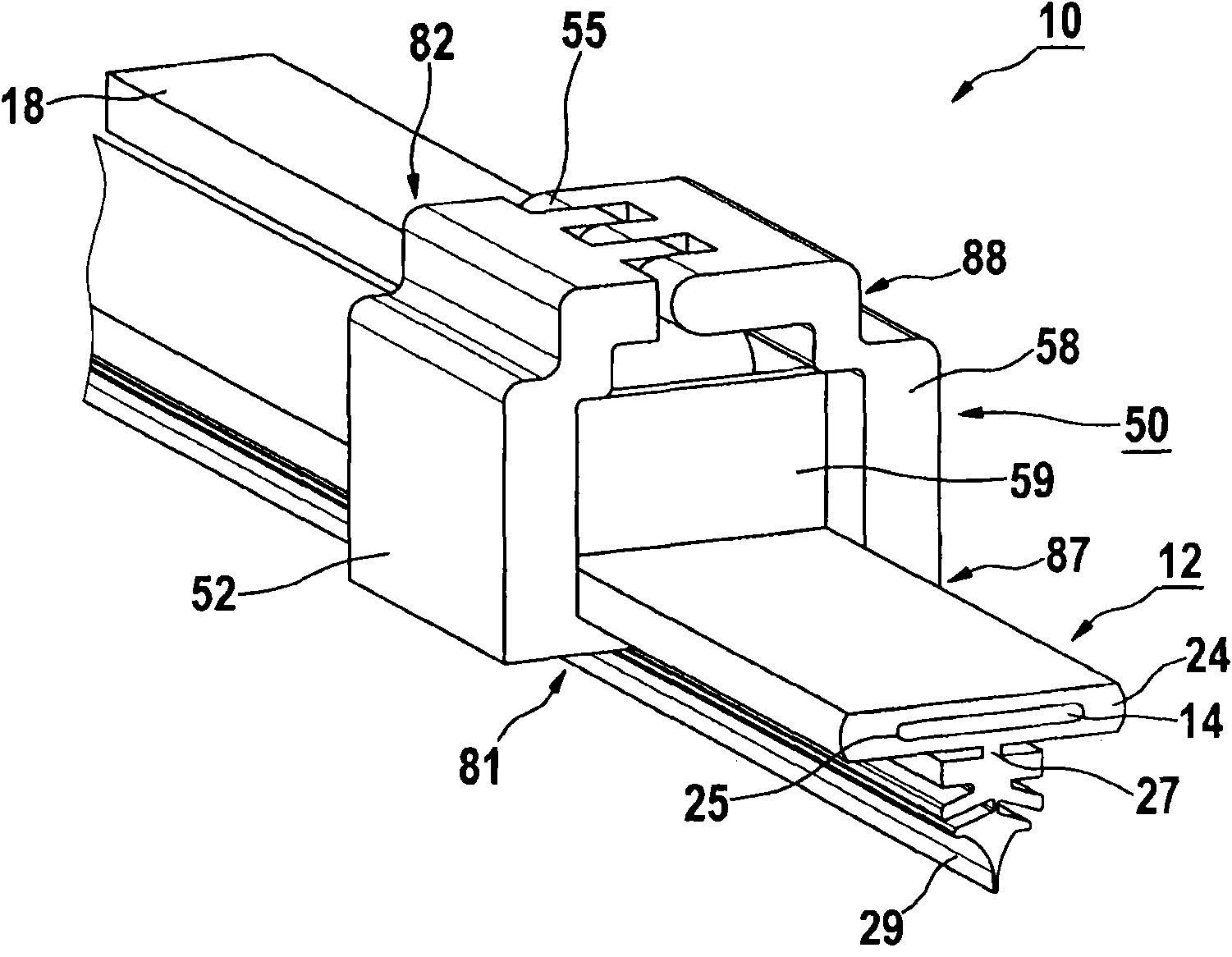

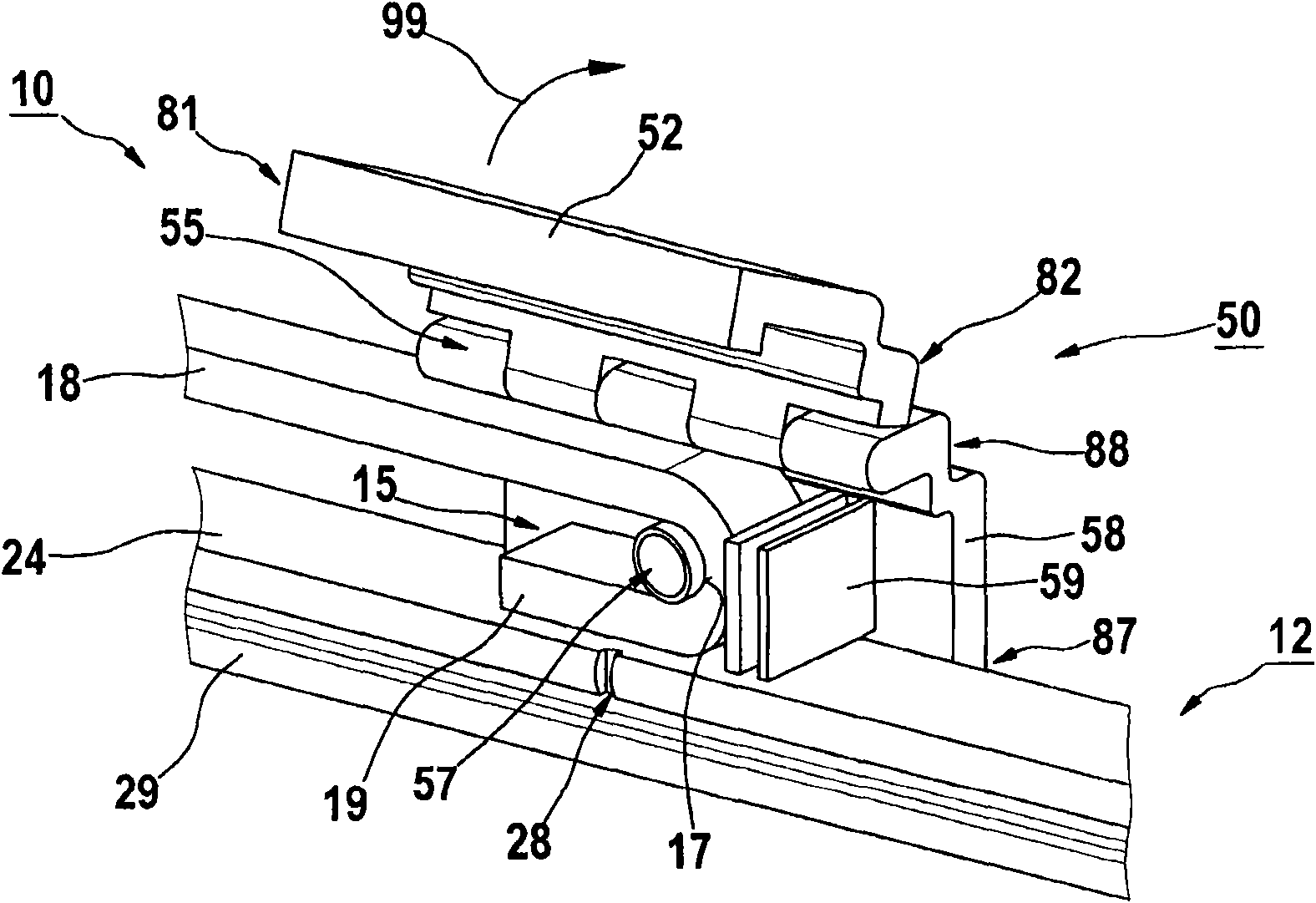

[0024] figure 1 Shown is a wiper blade 10 with a wiper strip 12 having a wiper lip 29 connected to a rear strip 24 via a pivot web 27 . An adapter unit 50 for connecting to the wiper arm 18 is fixed on the wiper strip 12 . With the aid of the wiper arm 18 , the wiper blade 10 for wiping can be guided through a glass 22 shown in dotted lines, such as a motor vehicle windshield.

[0025] According to one specific embodiment, the wiper blade 10 is designed as a jointless wiper blade, that is to say the wiper strip 12 and the wiper arm 18 are connected to one another via an adapter unit 50 without a substantially formed pivot axis. , so that the wiper arm 18 and the wiper strip 12 cannot pivot relative to each other. This type of connection is also referred to below as a "jointless connection" or "jointless fixation". Components that enable a relative movement between wiper arm 18 and wiper strip 12 due to material deformation, in particular elastic deformation, are not conside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com