Foldable-type turnaround rack

A revolving rack and foldable technology, applied in the field of revolving racks, can solve the problems of easy twisting of left and right baffles and rear baffles, ineffective use of storage space, and insufficient positioning and connection, so as to achieve easy and convenient folding operation and structural design. Compact, good load-bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

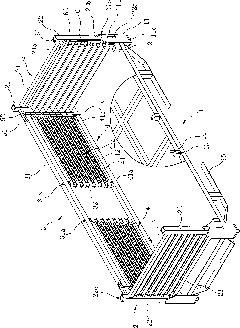

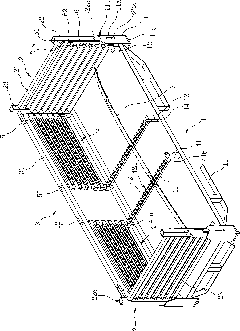

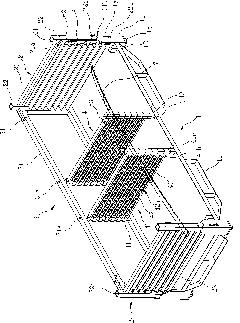

[0030] Such as Figure 1 to Figure 8 As shown, the foldable turnover frame includes a base 1, a middle frame 3 connected to the base 1, and two side frames 2 located on the left and right sides of the middle frame 3, and each side frame 2 and the middle frame 3 can be opposite to each other. The base 1 is independently folded and connected to the base 1;

[0031] Wherein, each of the four corners of the base 1 erects an L-shaped support plate 11 upwards, and the bottom edge of the base 1 is provided with a plurality of support feet 15;

[0032] Each side frame 2 comprises a cross bar 21 and two inside and outside vertical bars 22 that are connected with the end of the cross bar 21 respectively, and the bottom of each vertical bar 22 is positioned at the inner side of the L-shaped support plate 11, and each vertical bar 22 is connected by a pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com