Plating bath for producing diamond fretsaw

A technology of diamond wire saws and electroplating tanks, which is applied in the direction of plating tanks, etc., can solve the problems of large space occupation of equipment, decline in the quality of electroplating layers, and burnt metal wires, and achieve high production efficiency, long electroplating distances, and small footprints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

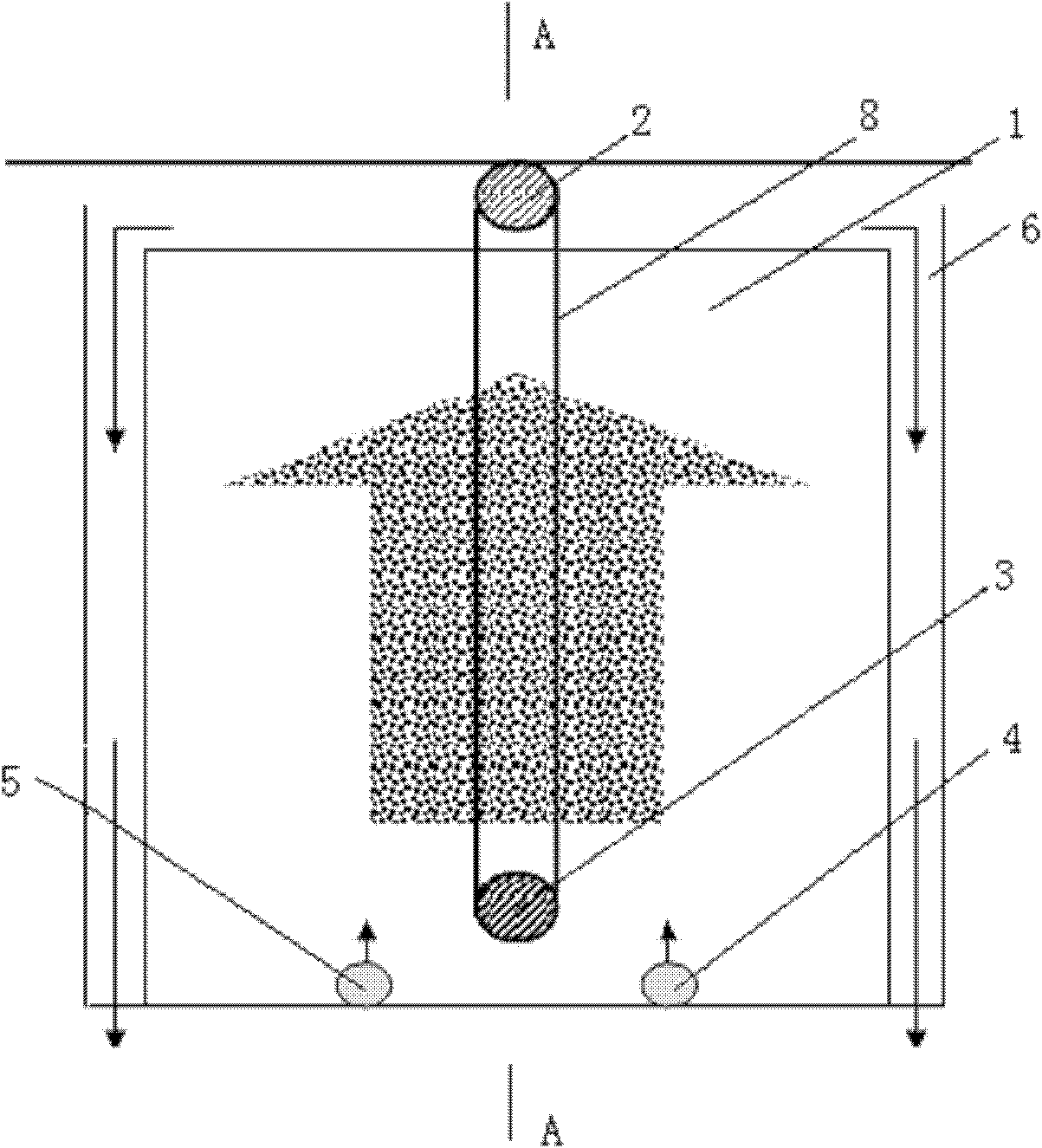

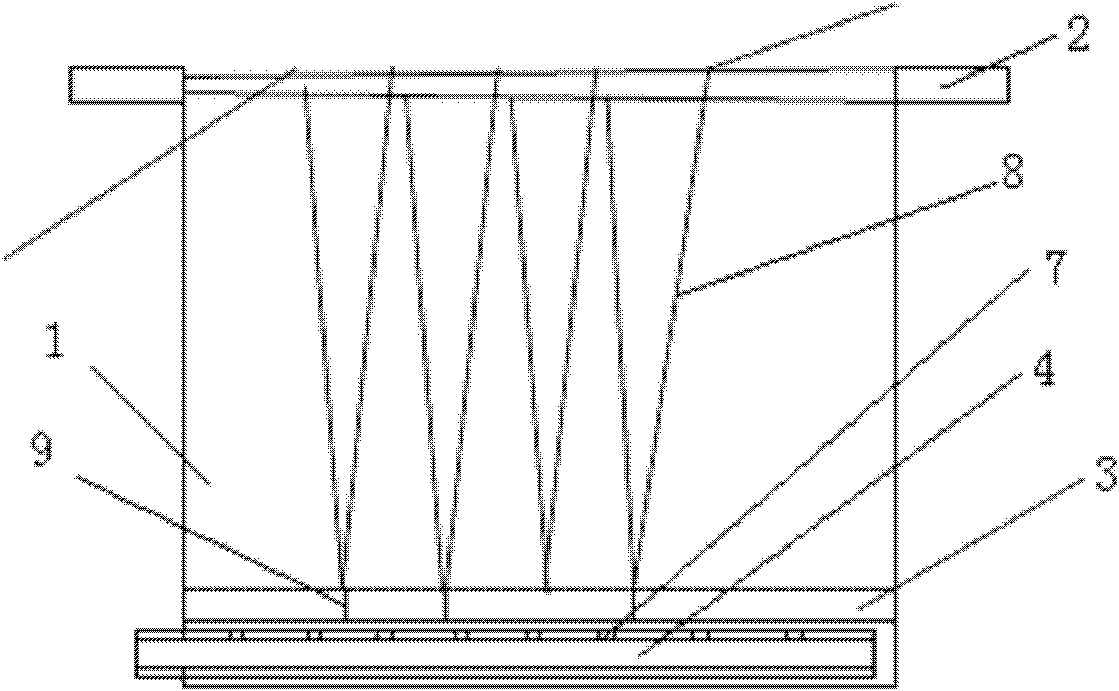

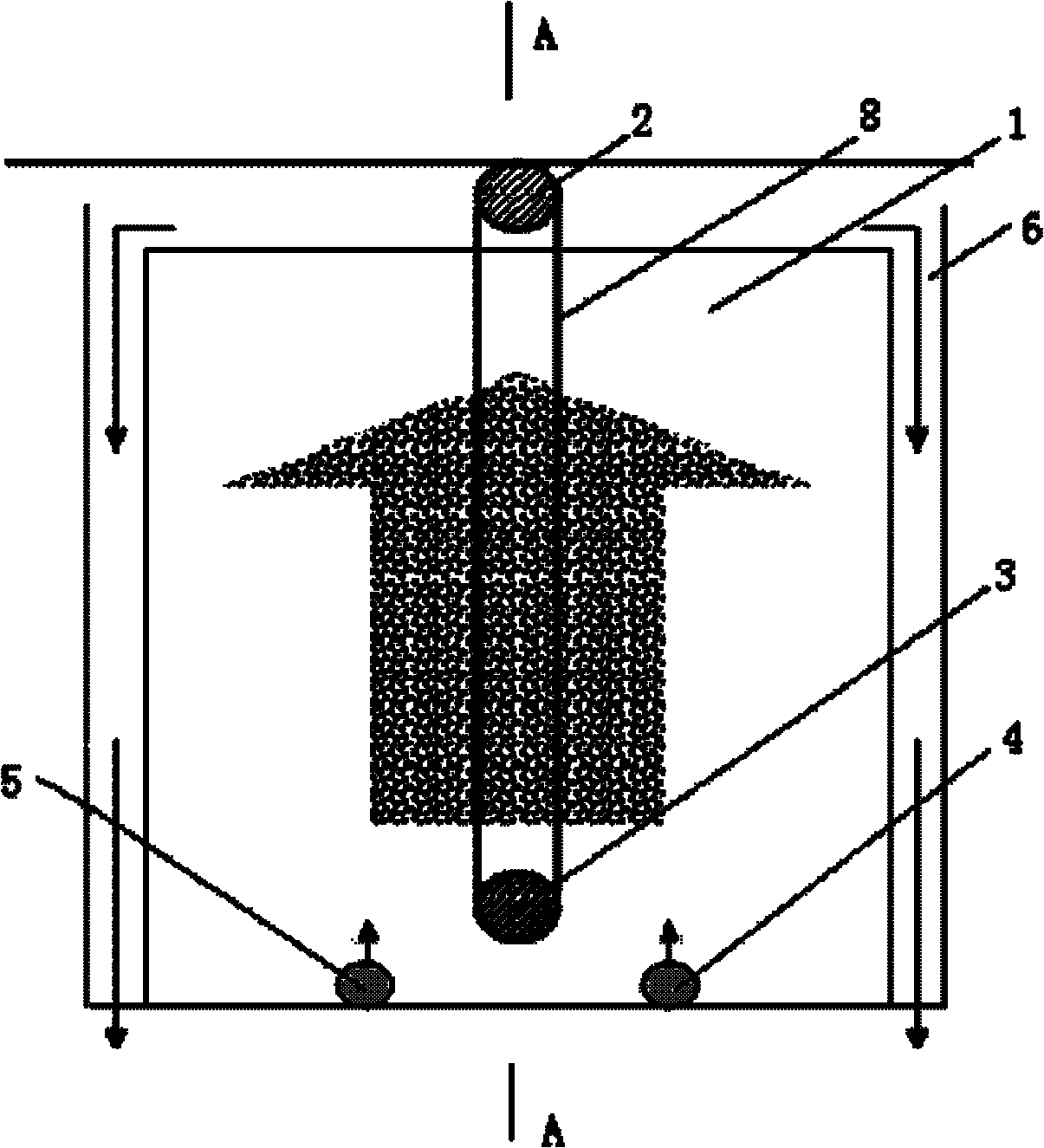

[0022] See attached figure 1 , 2 , an electroplating tank for producing diamond wire saws in the present invention, comprising an electroplating tank main body 1, a first rotating shaft 2 and a second rotating shaft 3 are arranged in parallel in the height direction of the electroplating tank main body 1, and at the bottom of the electroplating tank main body 1 There are at least two liquid inlet pipes 4 and 5 connected to the peripheral drive pump, and the two liquid inlet pipes 4 and 5 are arranged in the same direction as the first rotating shaft 2 and the second rotating shaft 3; the first rotating shaft 2 is conical, with a taper of 1:200-500 and connected to the peripheral drive device; the surface of the second rotating shaft 3 is evenly distributed with a plurality of annular grooves 9 in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com