Method for automatically centering and inversely installing vertical shaft pipelines

An automatic centering and vertical shaft technology, which is applied to vertical pipes, building components, buildings, etc., can solve the problems of steel pipe verticality and joint adjustment difficulties, damage to the steel pipe surface quality, low degree of automation, etc., to save welding lugs , Reliable installation quality and higher safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

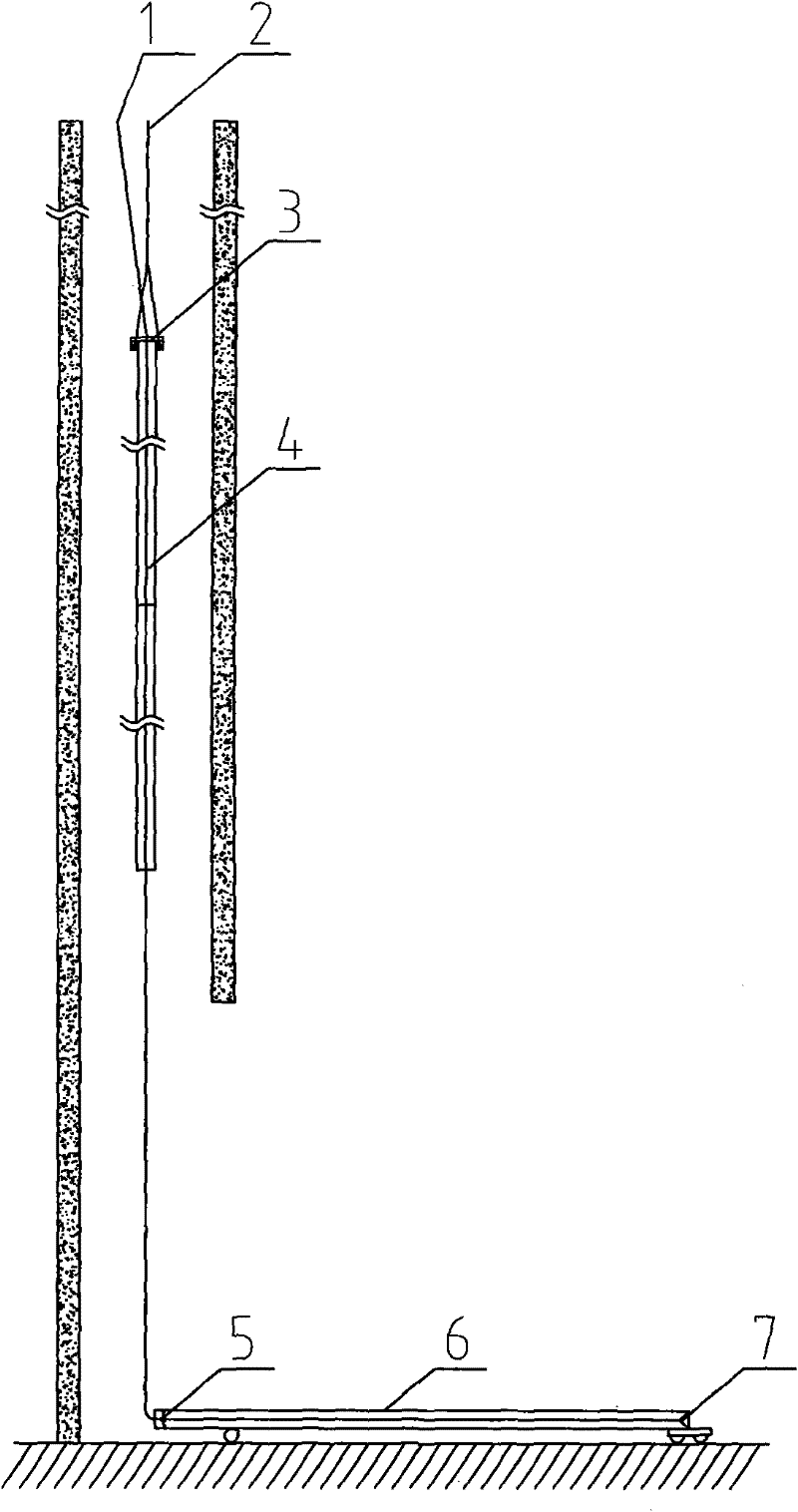

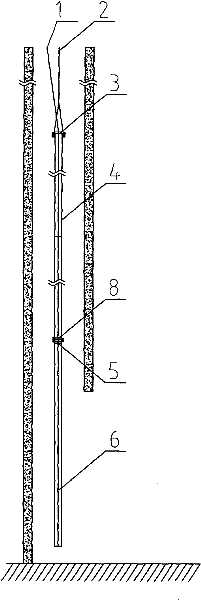

[0027] refer to figure 1 , figure 2 , a method for automatic centering and inversion of shaft pipelines, comprising the steps of:

[0028] 1: Select the specifications and models of the main and auxiliary hoists according to the structure of the building, the weight and length of the vertical shaft pipeline and the weight of the separately installed segmented steel pipes; this step mainly considers two factors: rated lifting capacity and rope capacity, layout Make sure the main and auxiliary winches are threaded and wound around the steel wire ropes of the main and auxiliary winches. The steel wire ropes of the main and auxiliary winches should go around the uppermost end of the final installation position of the steel pipe.

[0029] 2: According to the steel pipe specification and model and the steel wire rope 1 specification of the auxiliary hoist, make the center limit plate 3, the automatic centering plate 5, the automatic centering lifting fixture 7, the automatic cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com