Assay methods for memantine

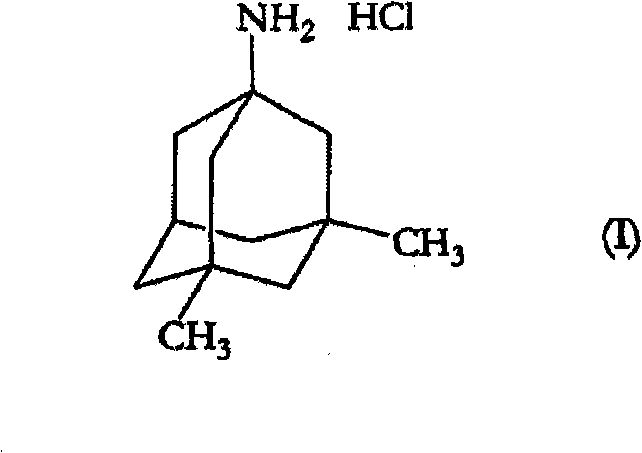

A technology of memantine and memantine hydrochloride, applied in chemical instruments and methods, measuring devices, preparation of organic compounds, etc., can solve problems such as obstacles and difficulties in derivatization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Embodiment 1: content uniformity test

[0080] GC system: Agilent 6890 or equivalent

[0081] Inlet sleeve: Agilent split / no split sleeve p / n 5183-4711

[0082] Column: ZB-1, 30m length, 0.32mm inner diameter, 1.0μm thin

[0083] film thickness

[0084] Precolumn: Deactivated fused silica tubing, 5m length, 0.32mm inner diameter

[0085] Carrier gas flow: Helium, 2.5mL / min (constant flow)

[0086] Inlet: Temperature: 340°C

[0087] Split injection: split ratio: 20:1

[0088] Gas Saver: On Time: 2.0 minutes

[0089] Flow: 20.0

[0090] Oven temperature: initial temperature 140°C

[0091] Start time 1 minute

[0092] Rate 1 10°C / min

[0093] Temperature 1 200°C

[0094] time 1 0 minutes

[0095] Rate 2 40°C / min

[0096] Temperature 2 340°C

[0097] time 2 1 minute

[0098] Detector: Flame Ionization Detector (FID) at 340°C

[009...

Embodiment 2

[0116] Embodiment 2: dissolution test

[0117] GC system: Agilent 6890 or equivalent

[0118] Inlet sleeve: Agilent split / no split sleeve p / n 5183-4711

[0119]Column: ZB-1, 30m length, 0.32mm inner diameter, 1.0μm thin

[0120] film thickness

[0121] Carrier gas flow: Helium, 2.5mL / min (constant flow)

[0122] Inlet: Temperature: 250°C

[0123] Split injection: split ratio: 10:1

[0124] Gas Saver: Off

[0125] Oven temperature: initial temperature 140°C

[0126] Start time 1 minute

[0127] Rate 1 10°C / min

[0128] Temperature 1 200°C

[0129] time 1 0 minutes

[0130] Rate 2 40°C / min

[0131] Temperature 2 300°C

[0132] time 2 2 minutes

[0133] Detector: Flame Ionization Detector (FID) at 300°C

[0134] Hydrogen 40mL / min

[0135] Air 400mL / min

[0136] Helium (refill) 22.5mL / min

[0137] Inject...

Embodiment 3

[0186] Embodiment 3: related substance test

[0187] GC system: Agilent 6890 or equivalent

[0188] Inlet sleeve: Agilent split / no split sleeve p / n 5183-4711

[0189] Column: ZB-1, 60m length, 0.32mm inner diameter, 1.0μm thin

[0190] film thickness

[0191] Carrier gas flow: Helium, 2.5mL / min (constant flow)

[0192] Inlet: Temperature: 250°C

[0193] Split injection: split ratio: 20:1

[0194] Gas Saver: On Time: 2.0 minutes

[0195] Flow: 20.0

[0196] Oven temperature: initial temperature 140°C

[0197] Start time 1 minute

[0198] Rate 1 2°C / min

[0199] Temperature 1 200°C

[0200] time 1 0 minutes

[0201] Rate 2 30°C / min

[0202] Temperature 2 300°C

[0203] time 2 5 minutes

[0204] Detector: Flame Ionization Detector (FID) at 250°C

[0205] Hydrogen 40mL / min

[0206] Air 400mL / min

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com