Improved applicability of lamps with electronic ballast without a protective earth conductor

A technology for electronic ballasts and illuminants, applied in the field of illuminants, can solve the problems of reducing electromagnetic compatibility contact voltage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

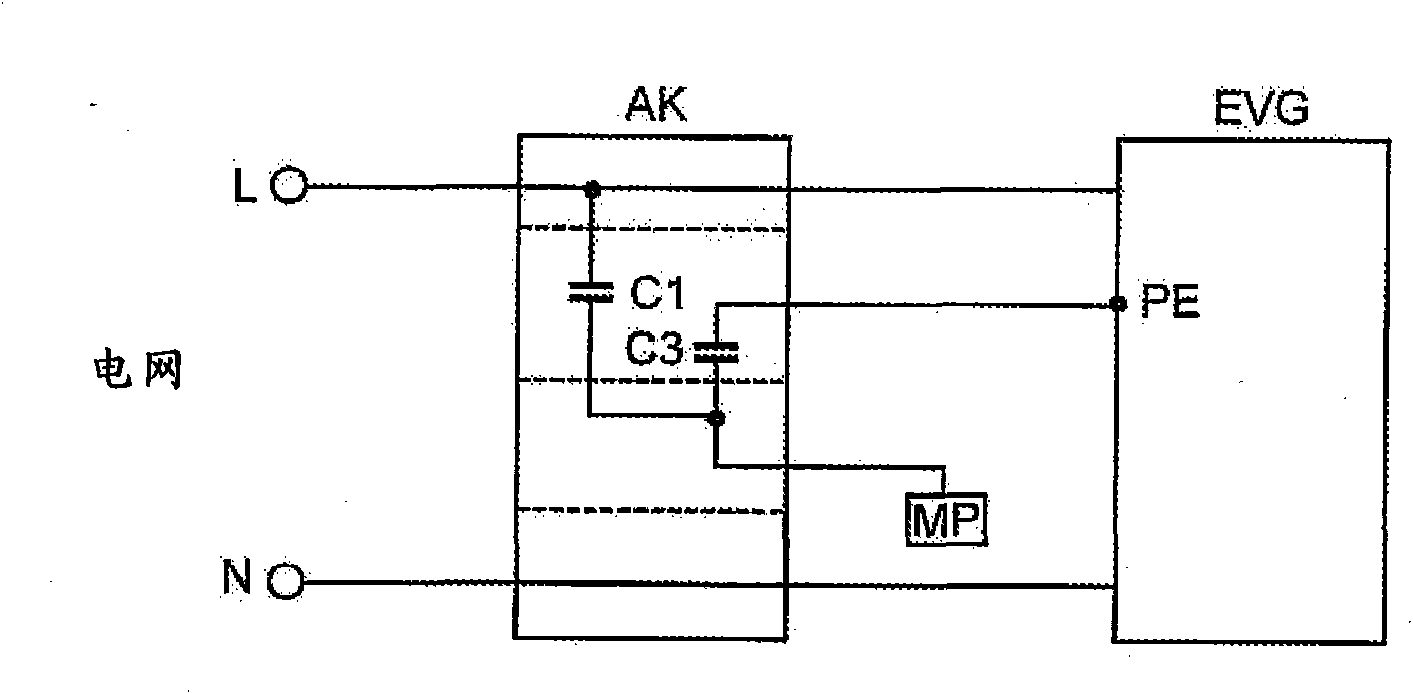

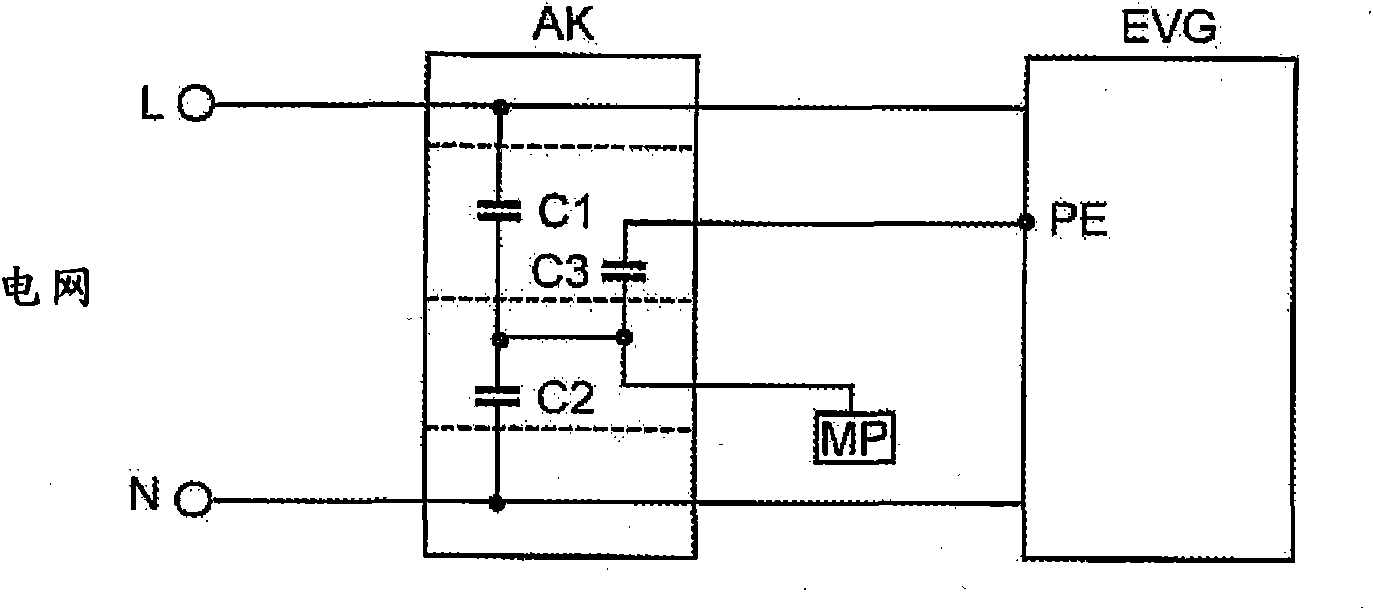

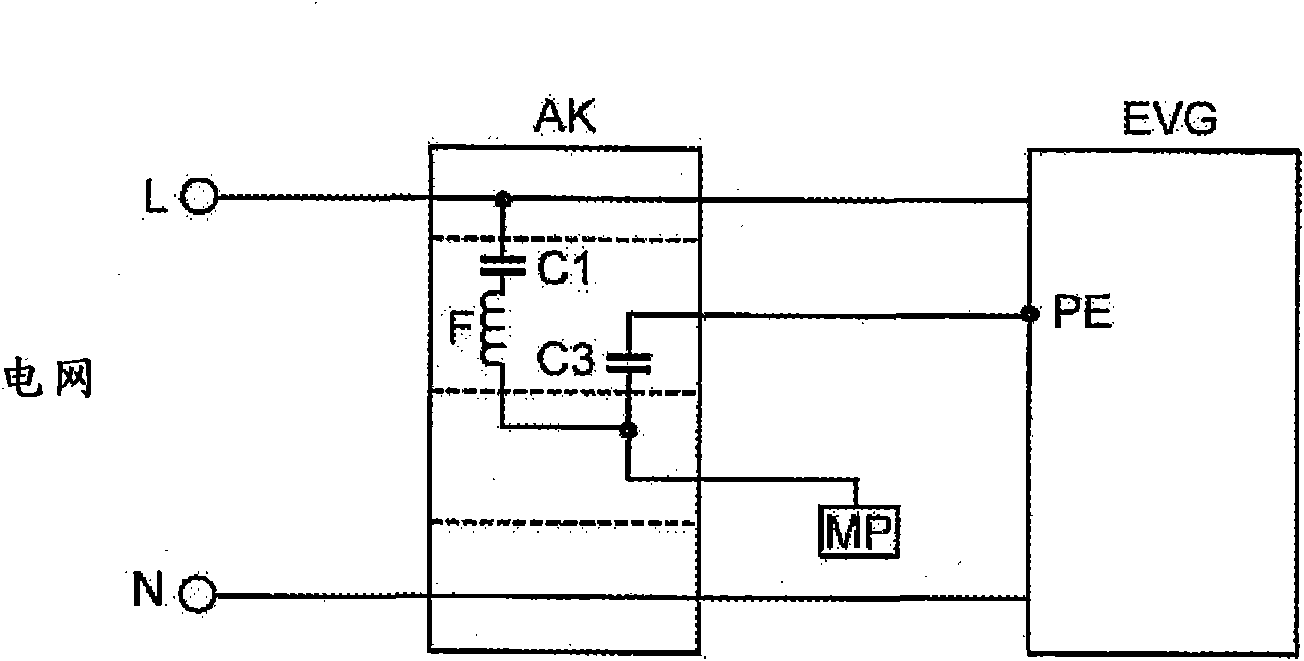

[0048] exist figure 1 The wiring of the circuit according to the invention in the luminaire is shown in a highly schematic block diagram in . Shown on the left is the grid terminal with the phase conductor L and the neutral conductor N, which is led to the illuminant connection terminal AK via a grid lead that is not further separated. The illuminant connection AK is a uniform plastic housing (shown by a rectangle) with the known per se embedded terminal contacts for the lines L and N, but without a PE connection contact. Capacitors C1 and C3 are Y-capacitors with a capacitance of 2.2nF or 1.5nF. The protective ground terminal PE of the EVG is connected to the isolated conductive luminous body part MP (such as the connection contact part of the housing, the metal reflector or the mounting piece or the mounting plate) through the capacitor C3. Two capacitors are held in the light connection terminals. The line between the capacitor C3 and the mounting plate MP can be constit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com