Shear type pulverizing cutter structure of food processor

A technology for food processors and crushing knives, which can be used in grain processing, household appliances, kitchen appliances, etc., and can solve the problems of increased manufacturing costs, large food particles, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The present invention is further described below in conjunction with the examples.

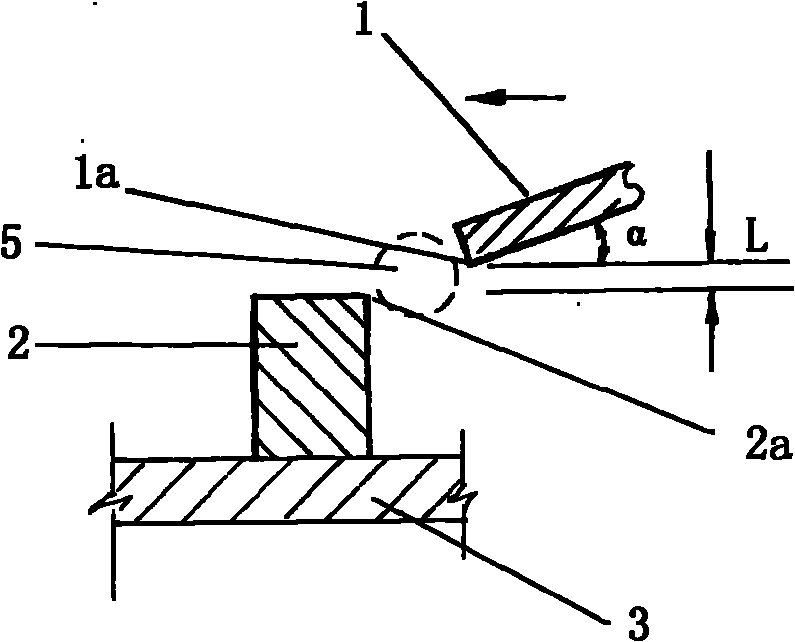

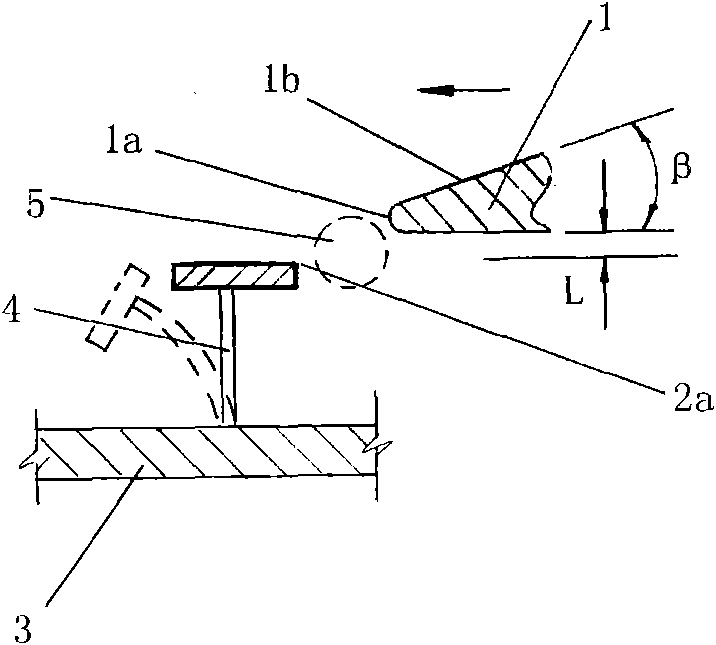

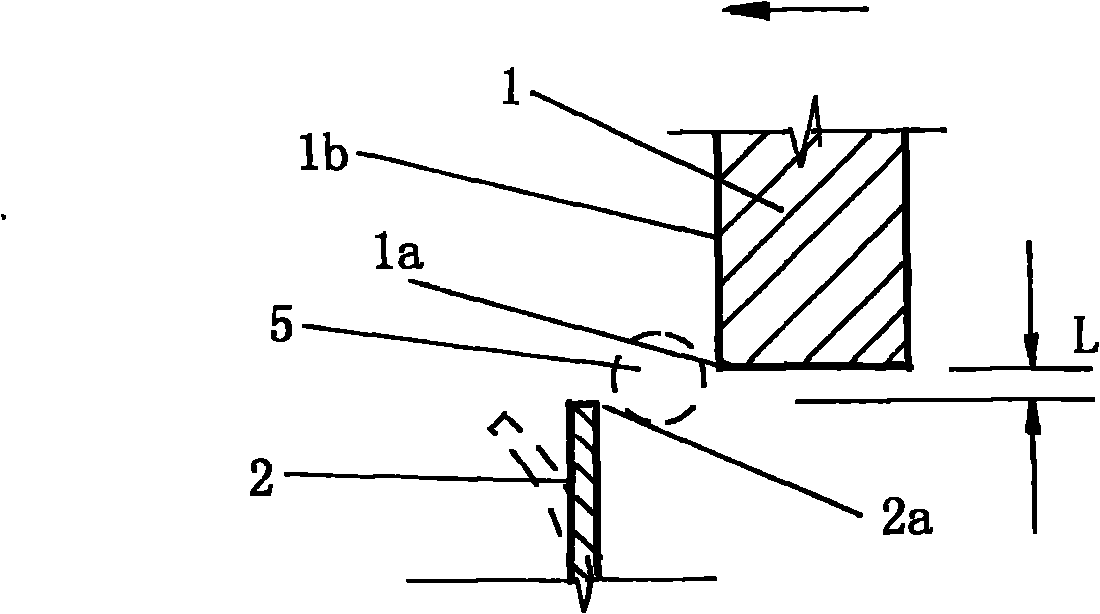

[0113] Main scissors body 1; matching scissors body 2; (second group) matching scissors body 22;

[0114] Food processor body part 3; supporting element 4 with scissors; food material 5 (dotted ball); machine head 6; bucket body 7; power shaft 8; guide tube 9; positioning column 10; positioning pin 11; ;Frame 66;

[0115] The edge 1a of the main scissors body 1; the rake face 1b of the main scissors body 1; the upper cover 1c of the main scissors body 1; the lower cover 1d of the main scissors body 1; The feed port 1e of the body 1; the working hole 1f of the main scissors body 1; the upper end surface 1g of the main scissors body 1 of the turntable type; the lower end surface 1h of the body 1 of the main scissors of the turntable type; Center mounting hole 1j;

[0116] The knife edge 2a of the scissors knife body 2; the lower end surface 2b of the scissors knife body 2; the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com