Grain mill

A technology of a pulverizer and a grinding mechanism, which is applied in the field of pulverizers, can solve the problems of plastic materials that are not easy to process and deform, and is difficult to chop and deform, so as to achieve automatic screening and cyclic processing, and increase the grinding effect. , the effect of improving the grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

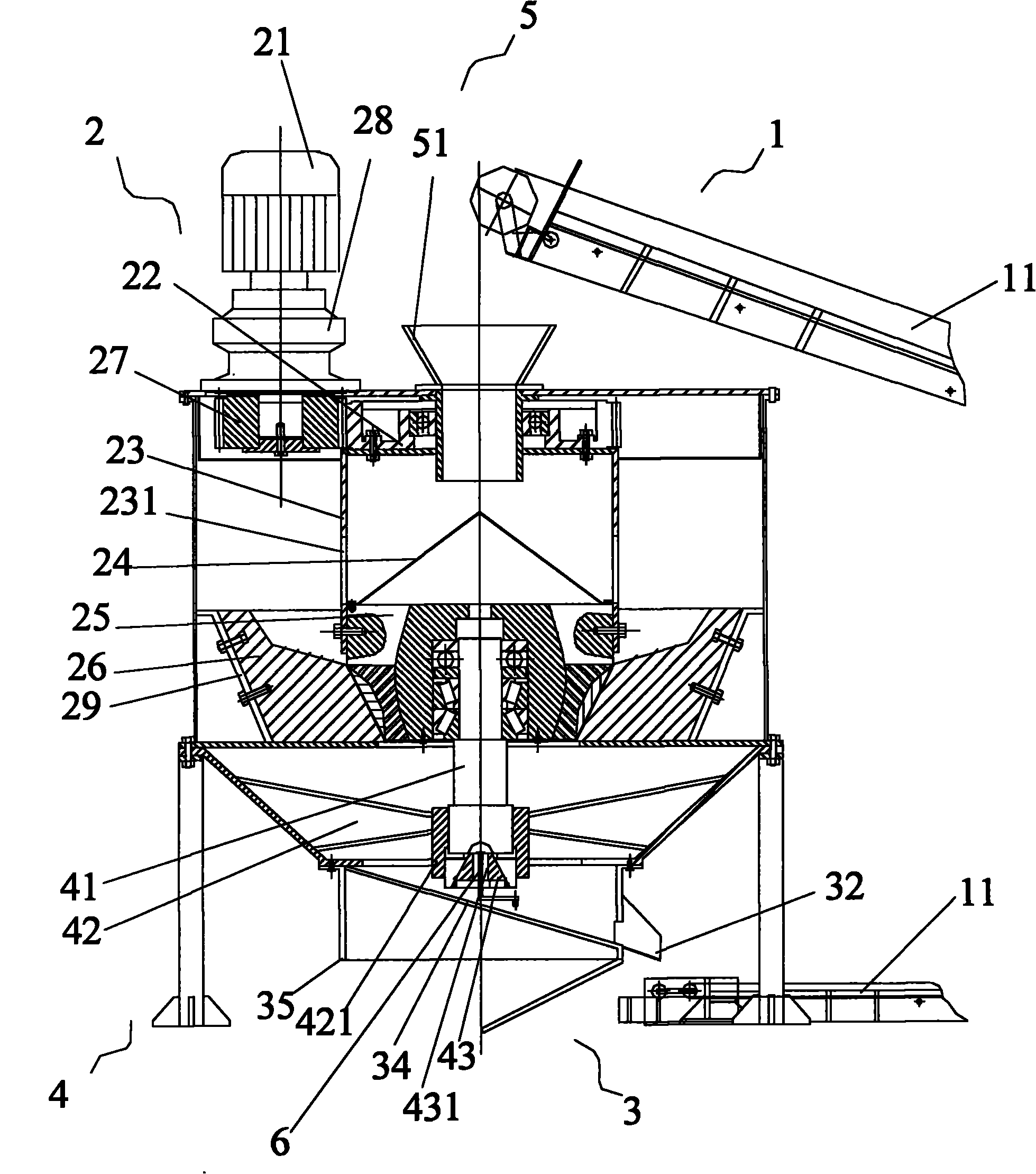

[0030] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

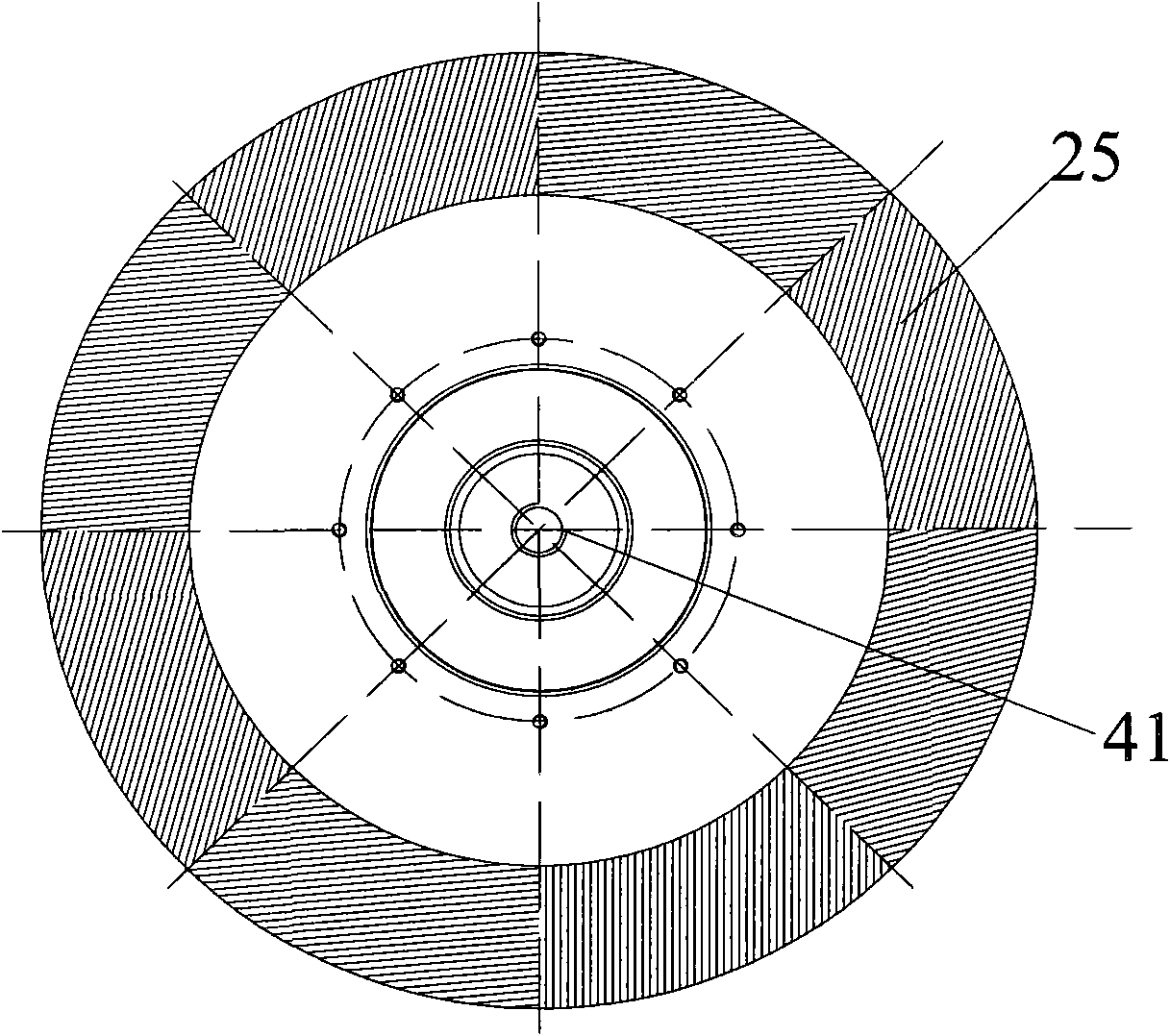

[0031] Such as figure 1 As shown, the pulverizer according to the embodiment of the present invention mainly includes a feeding mechanism 5, a grinding mechanism 2 arranged under the feeding mechanism 5, a screening mechanism 3 arranged at the bottom of the grinding mechanism 2, a support mechanism 4, a The return mechanism 1 is used to automatically send the semi-coarse material screened by the screening mechanism 3 back to the feeding mechanism 5, and the detachable adjustment member 6 is used to adjust the gap between the grinding areas.

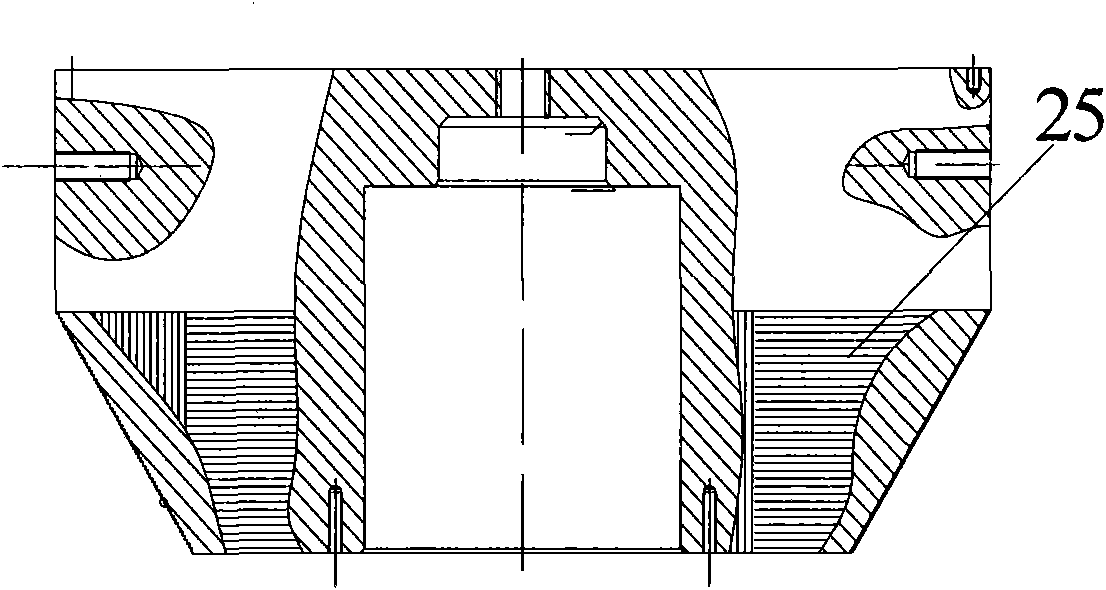

[0032] Wherein, the feeding mechanism 5 includes a hopper 51 , and the hopper 51 is located above the grinding mechanism 2 . In the grinding mechanism 2, the motor 21 drives the pinion 27 through the reducer 28 below, the pinion 27 meshes with the large gear 22, the large gear 22 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com