Hydraulic clamping device for batch plates

A hydraulic clamping and sheet metal technology, which is applied in positioning devices, sawing machine devices, clamping, etc., can solve the problems of not meeting the physical performance testing requirements, not being able to process sheet metal samples in batches, and poor processing sample precision, etc., to achieve processing The effect of low inspection cost, high operation efficiency and processing precision, and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

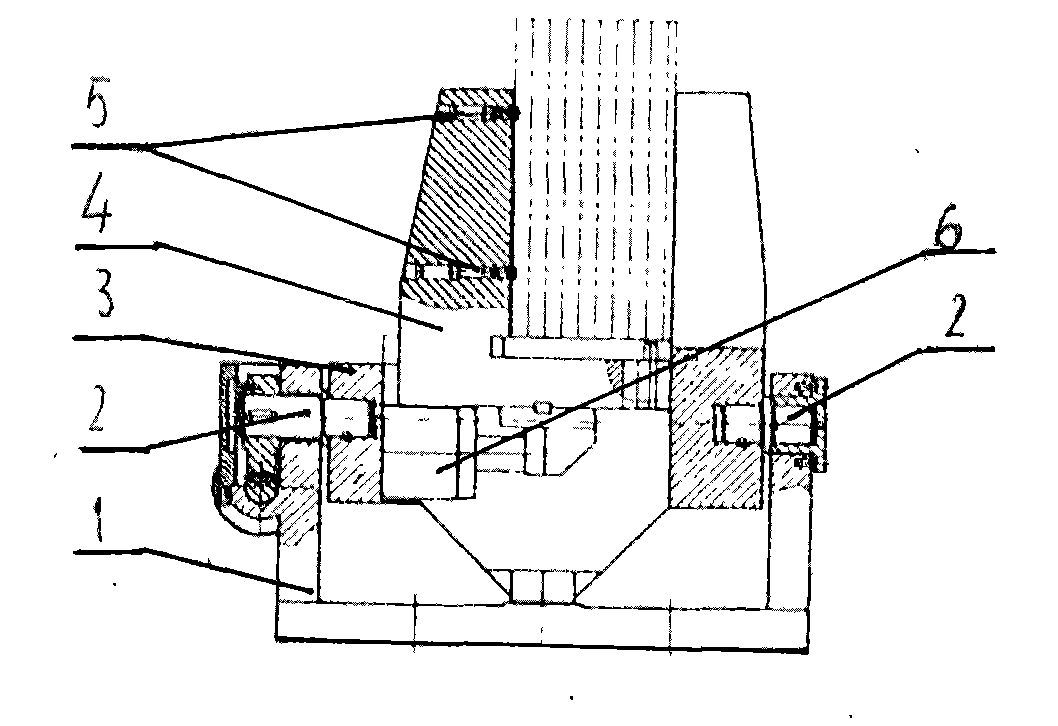

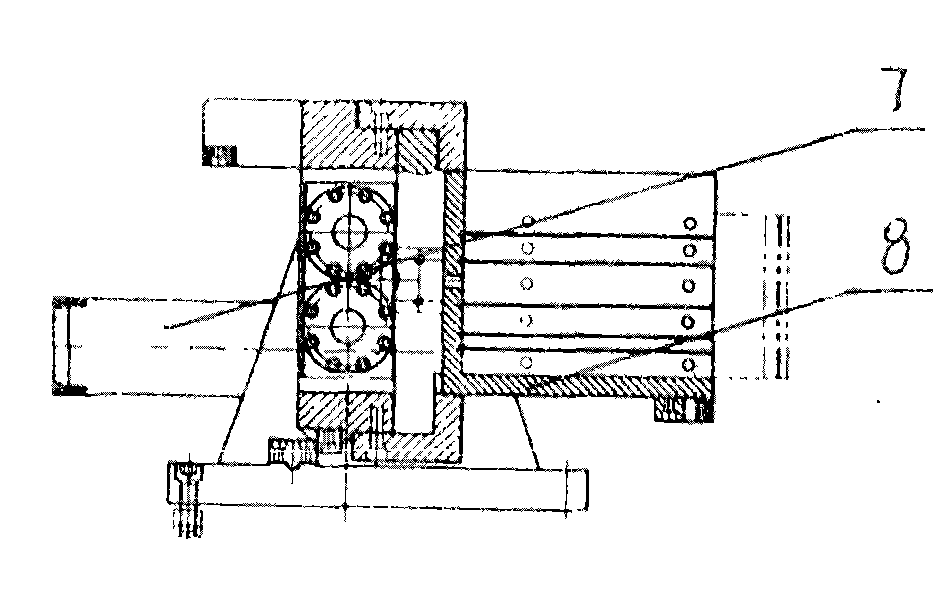

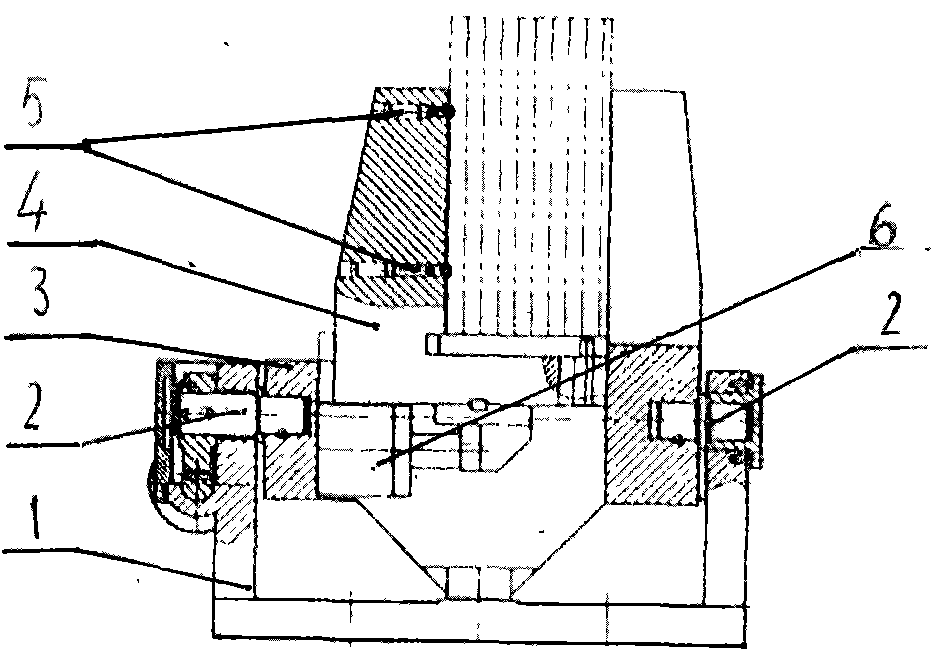

[0010] The best embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Batch plate hydraulic clamping device, which is composed of clamping base 1, turning shaft 2, fixed jaw 3, moving jaw 4, floating pressure head 5, clamping cylinder 6 and turning cylinder 7: turning shaft 2 and turning The oil cylinder 7 is assembled on the clamping base 1, the turning shaft 2 is connected with the turning oil cylinder 7, and the two fixed jaws 3 arranged oppositely are installed on the turning shaft 2, and can realize 90° turning, and the moving jaw 4 is installed on a On the fixed jaw 3 on the side, the clamping cylinder 6 is arranged on the fixed jaw 3, located below the movable jaw 4, and connected with the movable jaw 4, and the fixed jaw 3 and the movable jaw 4 are provided with a belt Saw matching slit, floating pressure head 5 fits on the movable jaw 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com