Multifunctional plate sample forming machine

A plate sample, multi-functional technology, applied in the preparation of test samples, sawing machine devices, metal sawing equipment, etc., can solve the problems of failure to meet standards, batch, high efficiency, sample accuracy does not meet the requirements, and cannot be processed in batches and other problems to achieve the effect of material saving, reliable performance and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

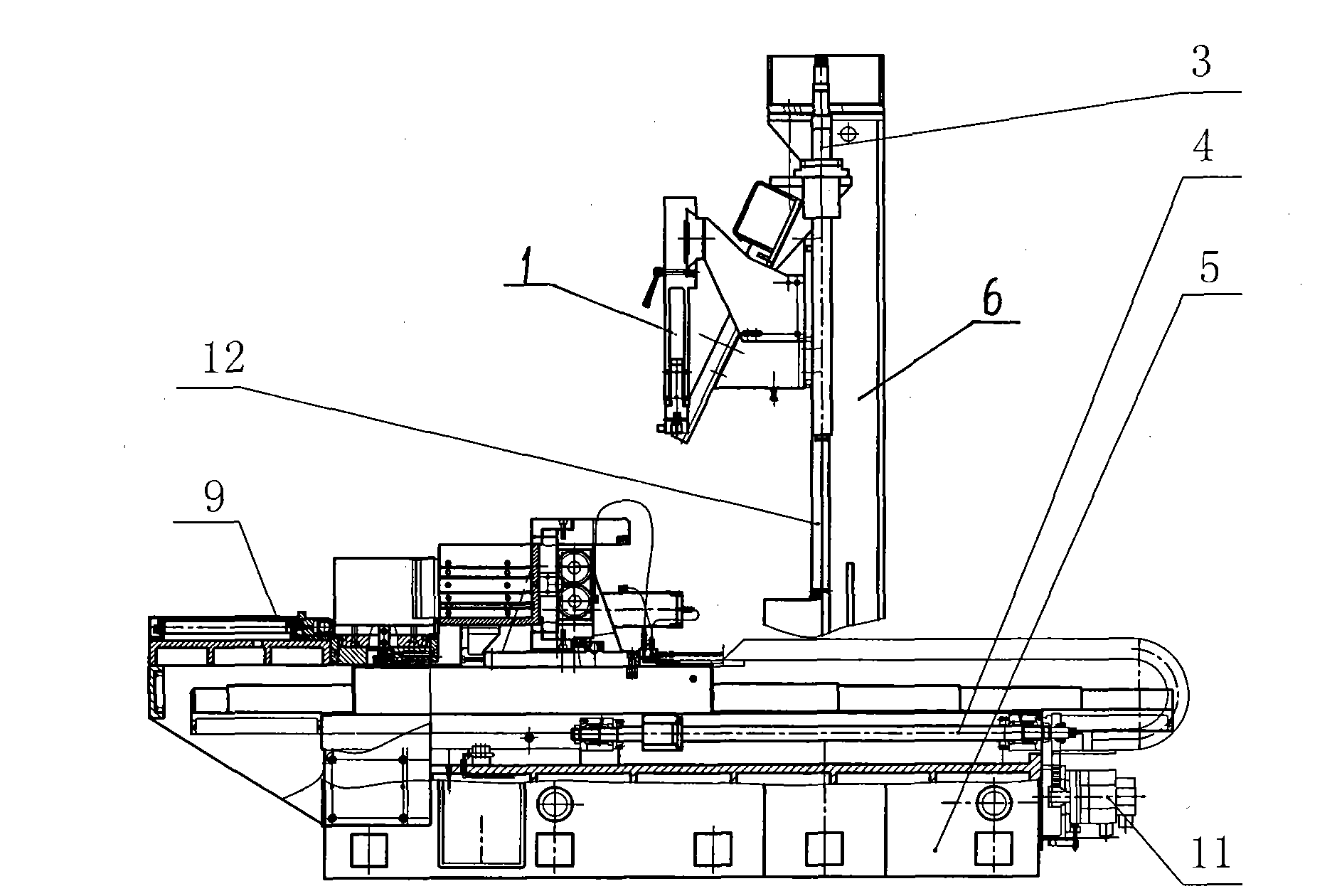

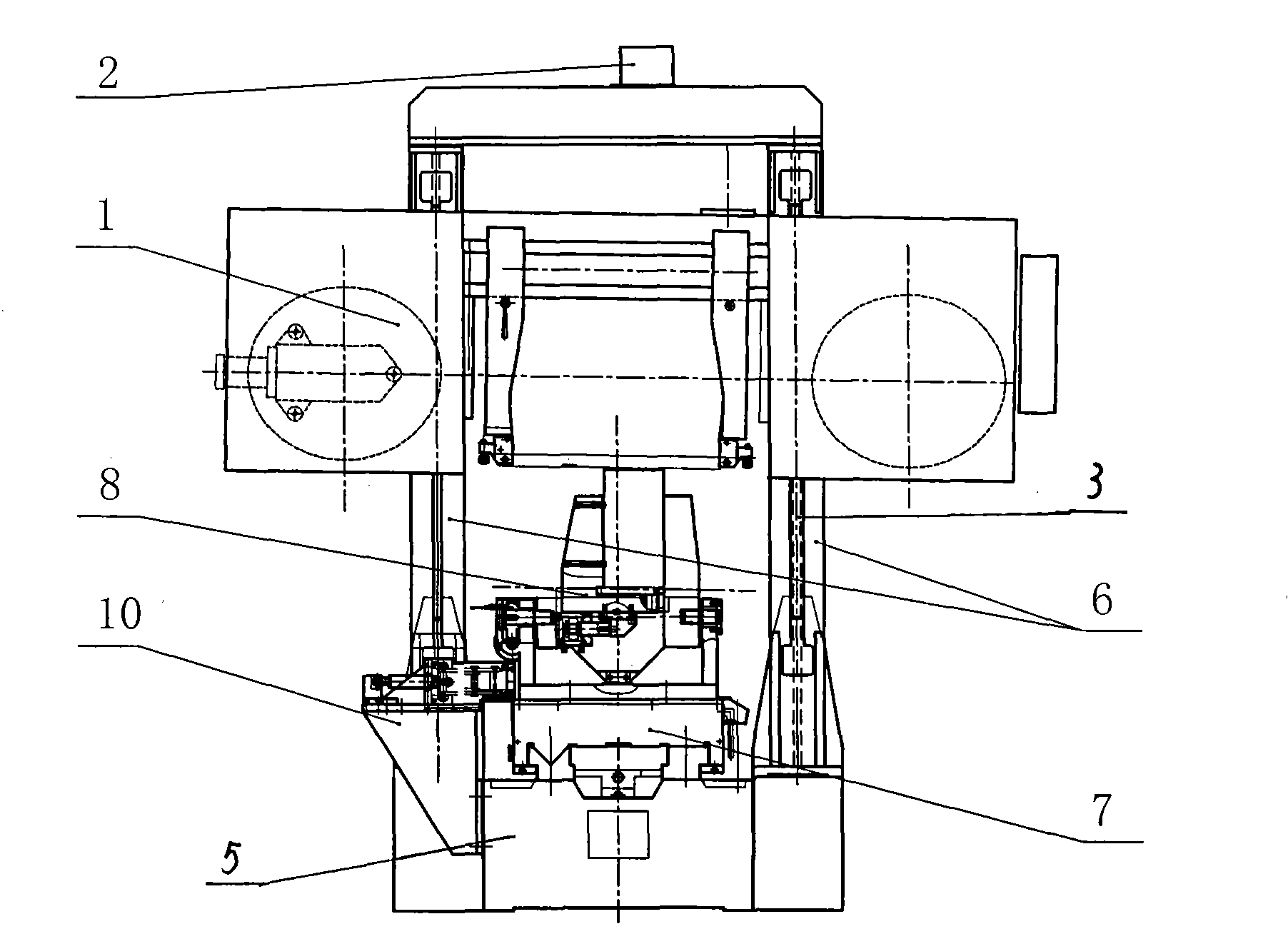

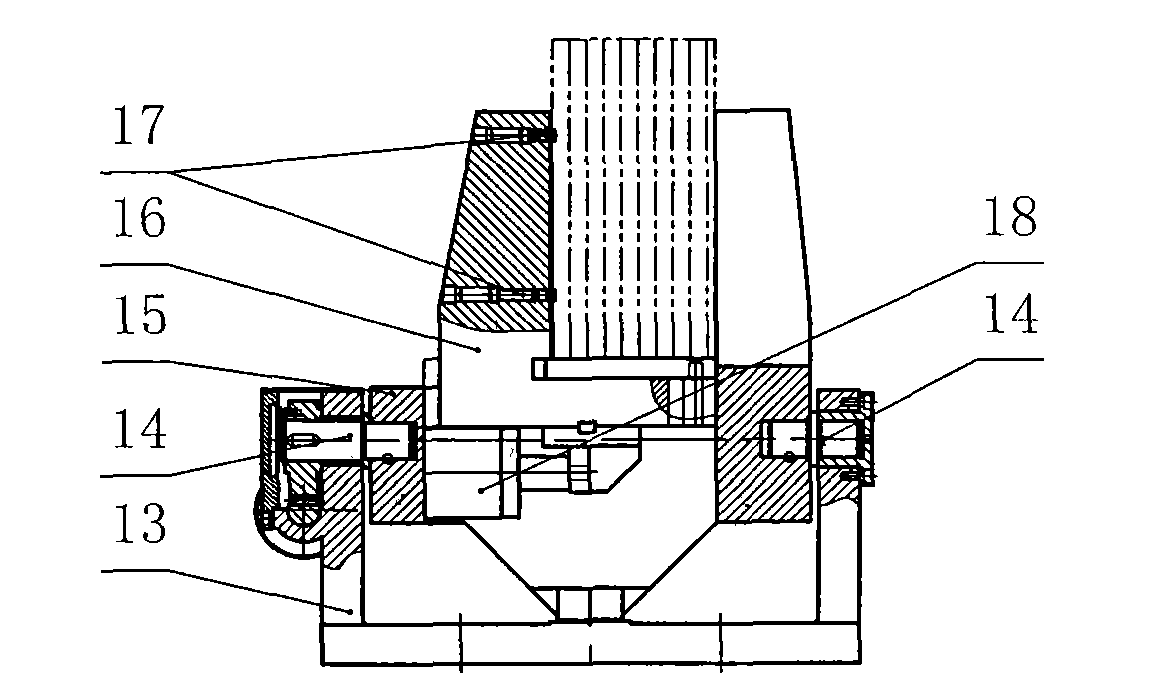

[0016] The best embodiment of the present invention will be described in detail below with reference to the accompanying drawings. Multi-functional forming machine for plate samples, two columns 6 with linear guide rails 12 are fitted parallel to each other on the bed 5, vertical ball screw 3 is rotatably installed on the columns 6, and at the upper end of the columns 6 The first servo motor 2 is fixed on the crossbeam, the first servo motor 2 is connected with the vertical ball screw 3, the band saw cutting device 1 can be moved up and down on the column 6, and is in contact with the linear guide rail 12; A worktable 7 that can move horizontally back and forth is installed on the bed 5 at the middle of the two columns 6. The horizontal ball screw 4 is rotatably arranged below the workbench 7 and connected to the workbench 7. 5 The second servo motor 11 is installed on the rear end, and the second servo motor 11 is connected to the horizontal ball screw 4 through the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com