Marine thruster with flow restraining rings

A technology of beam coils and propellers, which is applied in the direction of rotary propellers, can solve problems such as damage and low propulsion efficiency, and achieve the effect of avoiding friction or collision and improving propulsion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

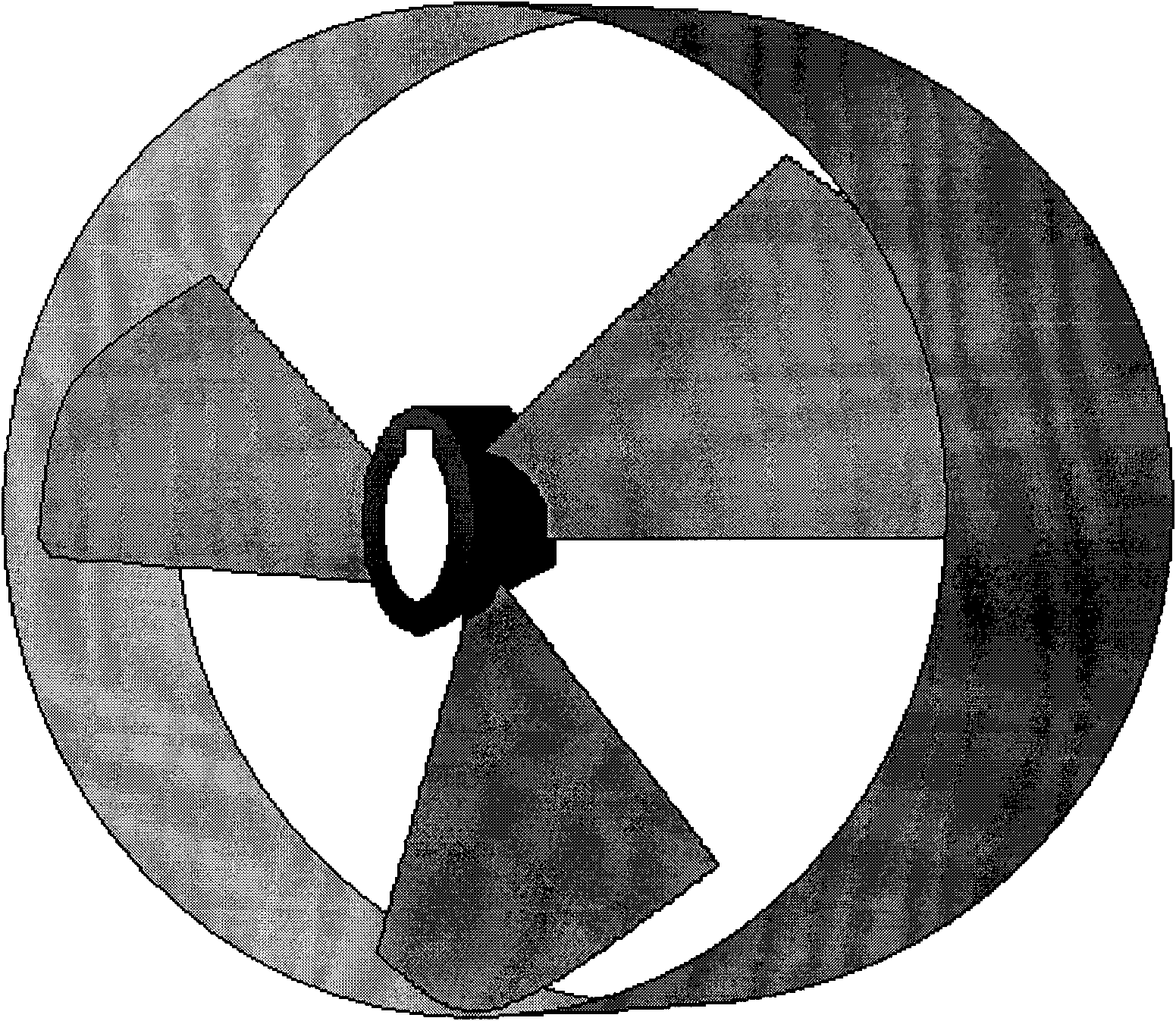

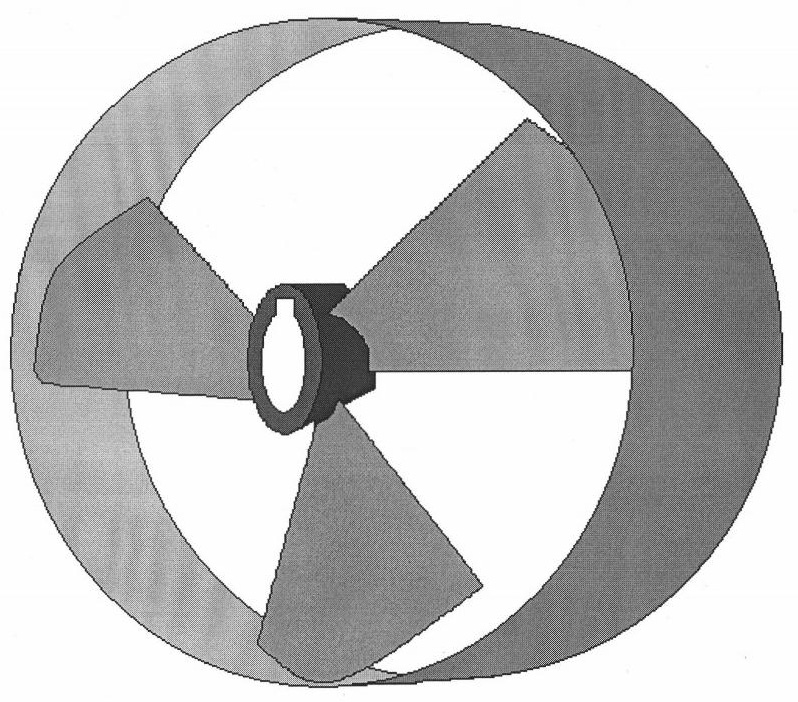

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0010] The blade pedicle (3) is provided with a keyway shaft hole (4) so as to be connected with the power shaft of the ship; the blade pedicle (3) is connected with a propulsion blade (2), and the other end of the propulsion blade (2) is connected to the beam circle (1), in this way, when the power shaft of the ship pushes the blade pedicle (3) to rotate, the propulsion blade (2) and the beam coil (1) will rotate together, that is, the effect of beam current and flow diversion is achieved, and the propulsion efficiency is improved , avoiding the hazard of friction or collision between the blade and the fixed shroud when the existing propeller is working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com