Battery module

A technology for battery modules and battery cores, which is applied to battery pack parts, circuits, electrical components, etc. It can solve the problems of insufficient bonding strength between the flexible shell and the bearing seat, and achieve the effect of improving the joint strength and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The detailed description and technical content of the present invention are described as follows in conjunction with the drawings. However, the drawings are only provided for reference and description, and are not used to limit the present invention.

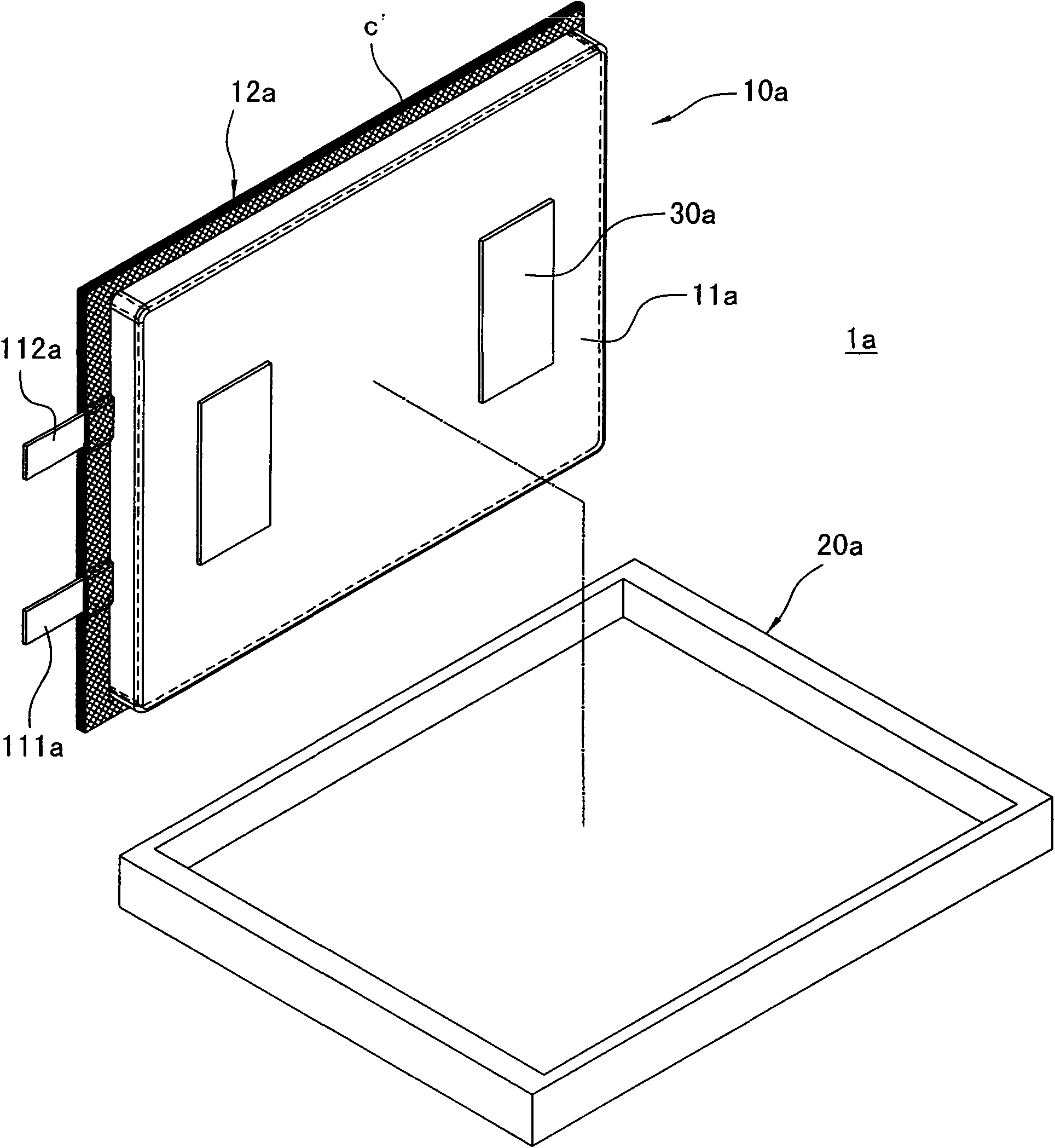

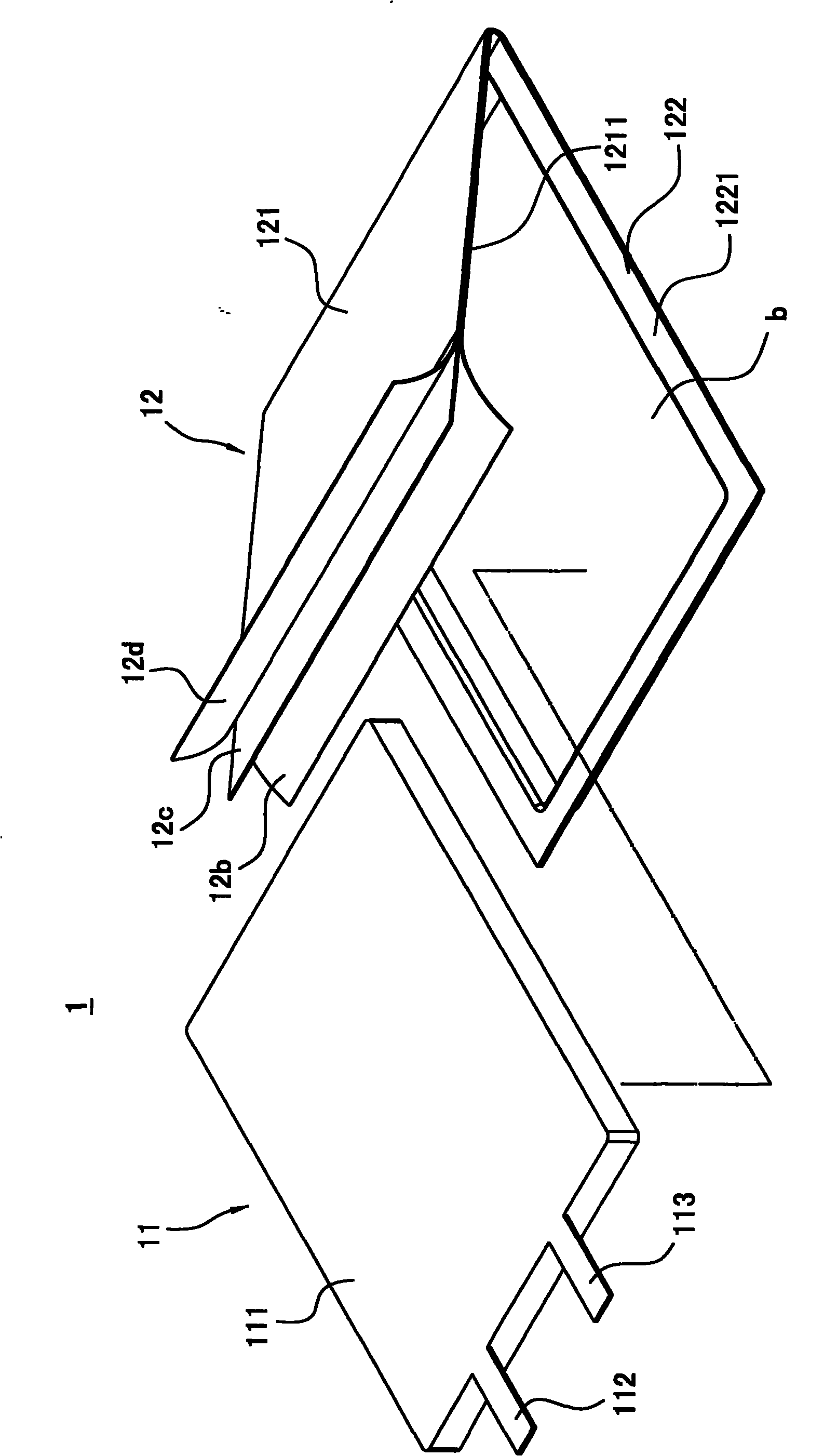

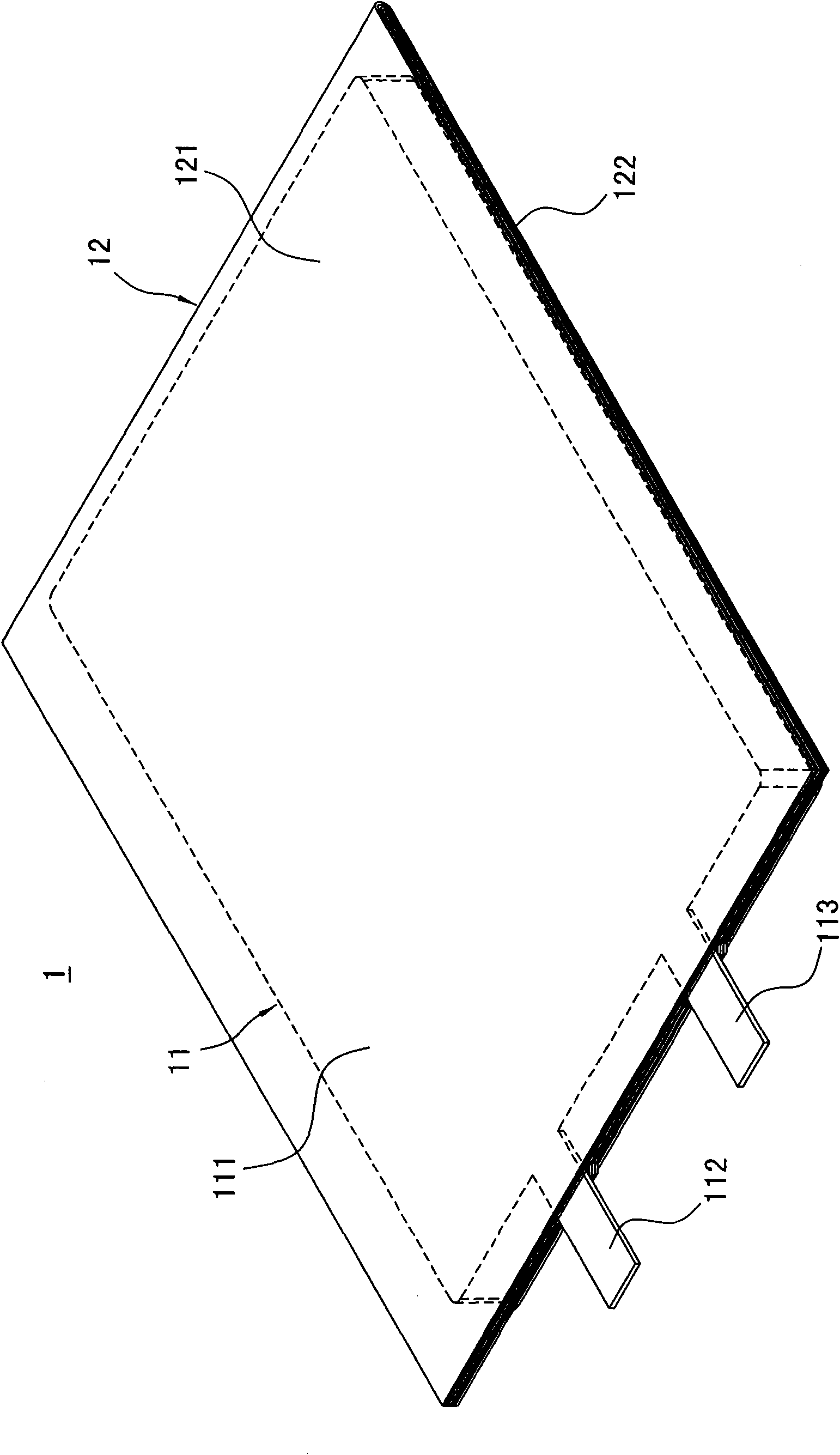

[0046] See figure 2 , Is a three-dimensional exploded view of the present invention, please refer to it together Figure 7 , The present invention provides a battery module 1, including a battery cell 11, a flexible casing 12 and a supporting base 20, wherein:

[0047] The battery core 11 has a main body 111 and two electrode sheets 112 and 113 extending outward from the main body 111. The two electrode sheets 112 and 113 are a positive electrode sheet 112 and a negative electrode sheet 113 spaced apart from the positive electrode sheet 112. In this embodiment, the main body 111 is a thin rectangular parallelepiped in the shape of a plate, but not limited to this. The positive electrode sheet 112 and the negative electrode she...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap