Method for producing cooked food

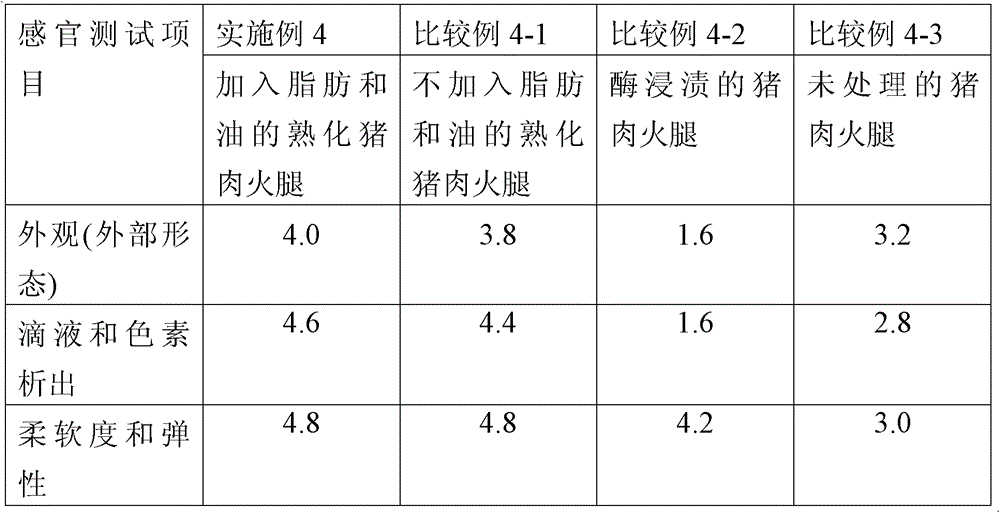

一种熟化食品、动物性食品的技术,应用在其味觉,获得的熟化食品,质地和风味被改善的熟化食品领域,能够解决难浸渍动物性食品材料、苦味物质改变、酶溶液色素析出等问题,达到增加视觉可口性、增加满足感、增加嫩度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Chunks of beef rump from Australia were frozen at -30°C in the freezer. Completely frozen meat was partially thawed using a microwave (NationalNE-SV30HA) and cut perpendicular to the long axis of its muscle fibers. Beef rump steaks with a maximum longitudinal width of 10 cm, a maximum transverse width of 7 cm and a thickness of 1.5 cm were prepared at a cutting interval of 1.5 cm. Prepared steaks are thawed completely in the refrigerator. The thawed beef round was soaked in an enzyme solution having protease activity (Protease N "Amano" G, manufactured by AmanoEnzyme, Inc.) adjusted to 0.5% by mass using a phosphate buffer solution (pH 5.8) After 1 minute, take it out and wrap it in a wrapping container. The container was placed under a reduced pressure condition of 0.01 MPa, and the food material was kept in an expanded state for 1 minute. Thereafter, the reduced pressure condition was released, and the degree of vacuum was increased again to reach a pressure of 0.0...

Embodiment 2

[0067] Chicken breast fillets were frozen at -30°C in the refrigerator. Fully frozen chicken breast strips were partially thawed in a freezer and cut perpendicular to the long axis of their muscle fibers. Chicken breast fillets with a maximum longitudinal length of 5 cm, a maximum transverse length of 1.5 cm and a thickness of 1.0 cm were prepared with a cut interval of 1.0 cm. Prepared chicken breast strips are thawed completely in the freezer. Thawed chicken breast slices were soaked in an enzyme solution with protease activity (Bromelain F, manufactured by AmanoEnzyme, Inc.) adjusted to 0.5% by mass using a phosphate buffered saline solution (pH5.8) for 5 After a few minutes, take it out and wrap it in a packing container. The container was placed under a reduced pressure condition of 0.01 MPa, and the food material was kept in an expanded state for 5 minutes. Thereafter, the reduced pressure condition was released, and the degree of vacuum was increased again to reach a...

Embodiment 3

[0074] Calamari (Japanese flying squid) was frozen at -30°C in a refrigerator. Completely frozen squid was partially thawed using a microwave (NationalNE-SV30HA) and cut longitudinally perpendicular to the long axis of its muscle fibers. Squid slices with a maximum longitudinal length of 10 cm, a maximum transverse length of 0.5 cm and a thickness of 0.5 cm were prepared at a cutting interval of 0.5 cm. Prepared squid fillets are completely thawed in the freezer. Thawed squid slices were soaked in an enzyme solution having protease activity (papain W-40, manufactured by AmanoEnzyme, Inc.) adjusted to 0.5% by mass using a phosphate buffer solution (pH 5.8) for 1 minute After that, take it out and wrap it in a packing container. The container was placed under a reduced pressure condition of 0.01 MPa, and the food material was kept in an expanded state for 1 minute. Thereafter, the reduced pressure condition was released, and the degree of vacuum was increased again to reach a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com