Clamp special for large insulation sintered blocks

A technology of thermal insulation blocks and core tools, applied in the direction of molds, etc., can solve the problems of inconsistent building energy conservation requirements, and achieve the effect of facilitating technology promotion and social application, accurate dimensions, and ensuring standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

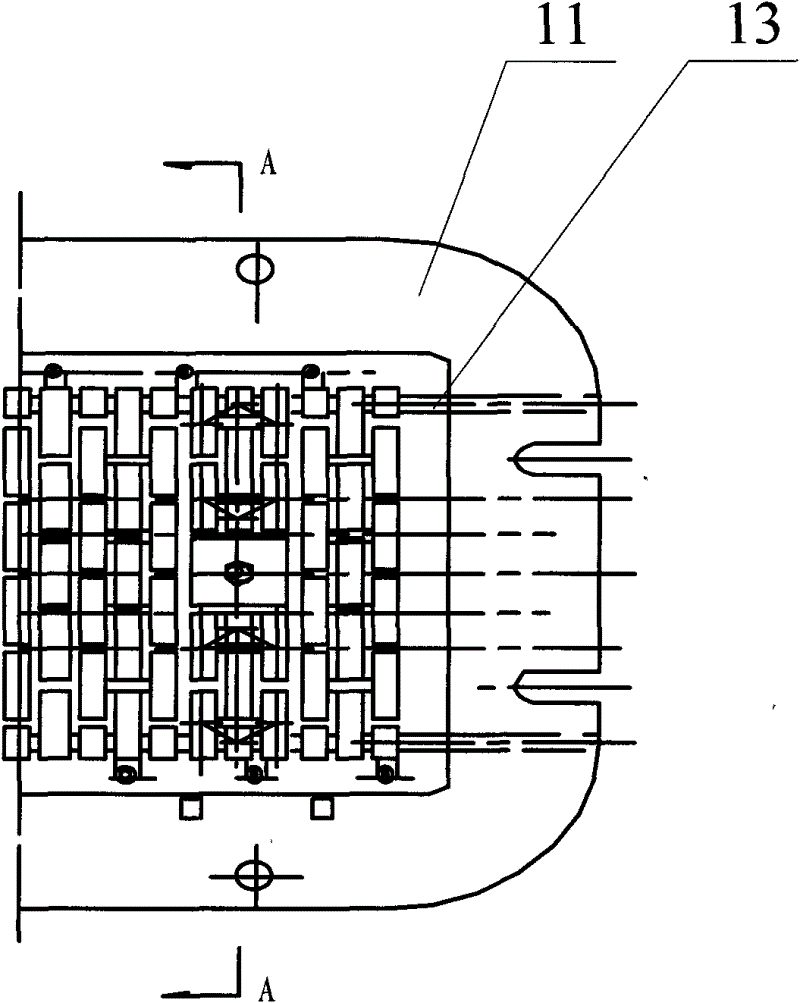

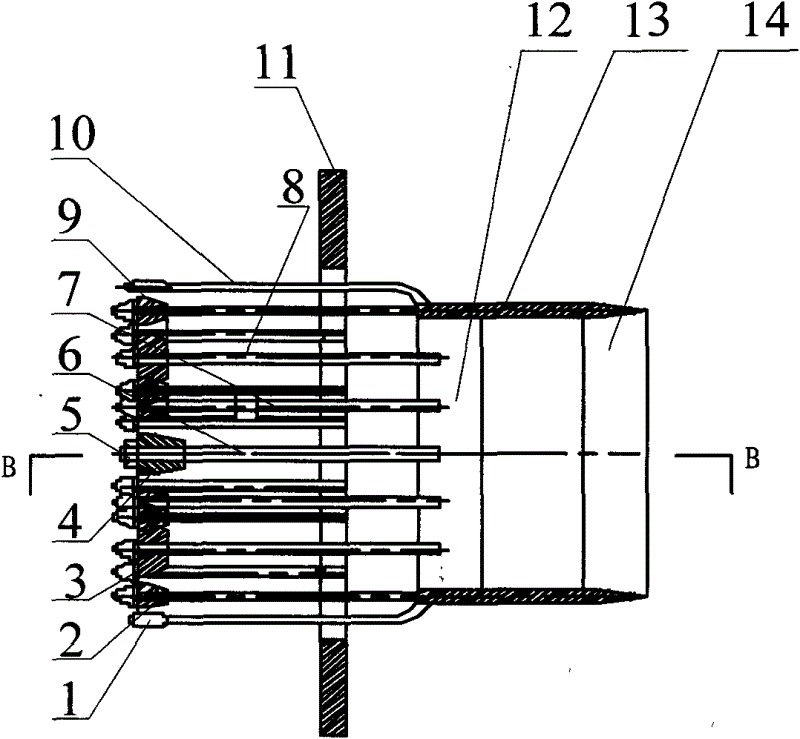

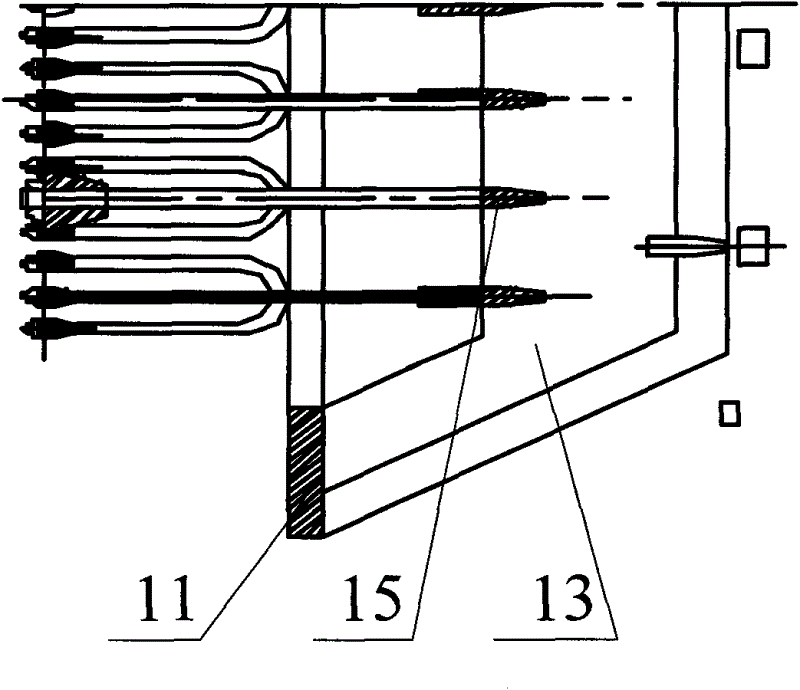

[0028] Attached below figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13 describe an embodiment of the present invention.

[0029] The special core tool for sintering large thermal insulation blocks includes a large knife rest 13, a small knife rest 12, a supporting knife rest 15, a core rod, a core head and a flange plate 11. The corners of two large knife rests 13 are fixed together with flange plate 11 respectively, connect with support knife rest 15 between two large knife rests 13, large knife rest is trapezoidal, its rear end is shaped on double-sided blade 16, and front end is shaped on positioning The notch I18 of welding small knife rest; Its rear end is shaped on a double-sided blade 16, and the front end is shaped on a plurality of notches II17 for positioning welding core rods; the core head is set on the top of the corresponding core rod and fixed with a nut; the core rod includes core rod one 6, core rod Two 7, core rod three 8 and core rod four 10; the core r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com