Nano silver dispersion and jet printing ink

A technology of nano-silver and dispersion liquid, applied in ink, application, coating and other directions, can solve the problems of instability of nano-silver dispersion and achieve the effect of good electrical conductivity

Inactive Publication Date: 2010-08-25

IND TECH RES INST

View PDF3 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

And it discloses the use of increasing the silver content to enhance the conductivity, but because it is a nitro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

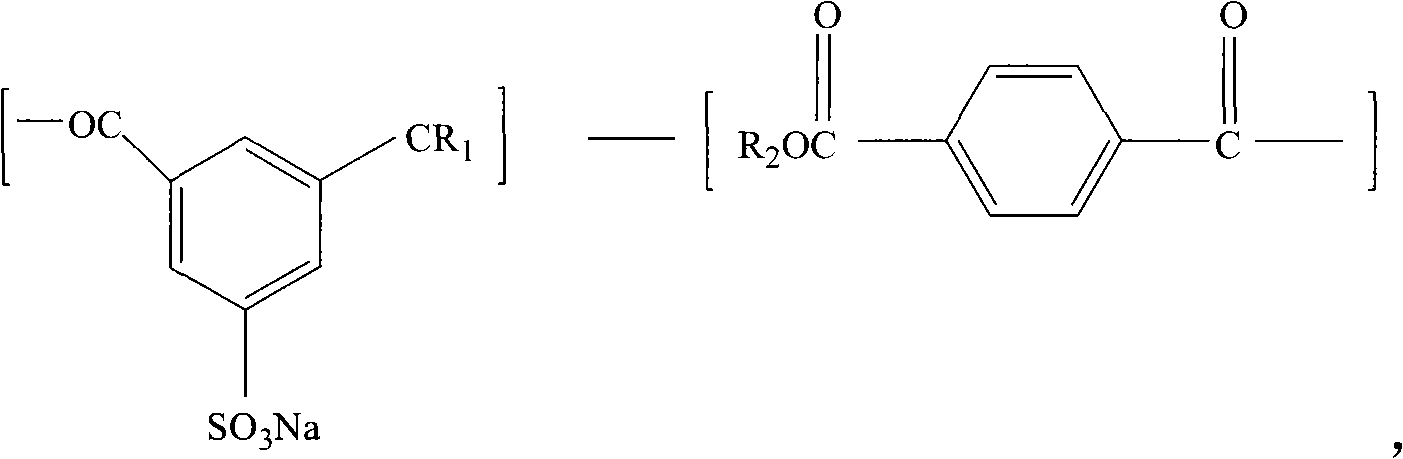

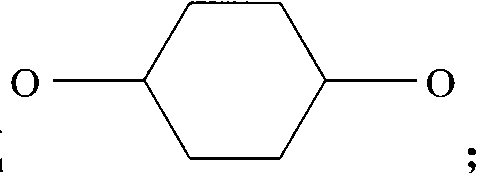

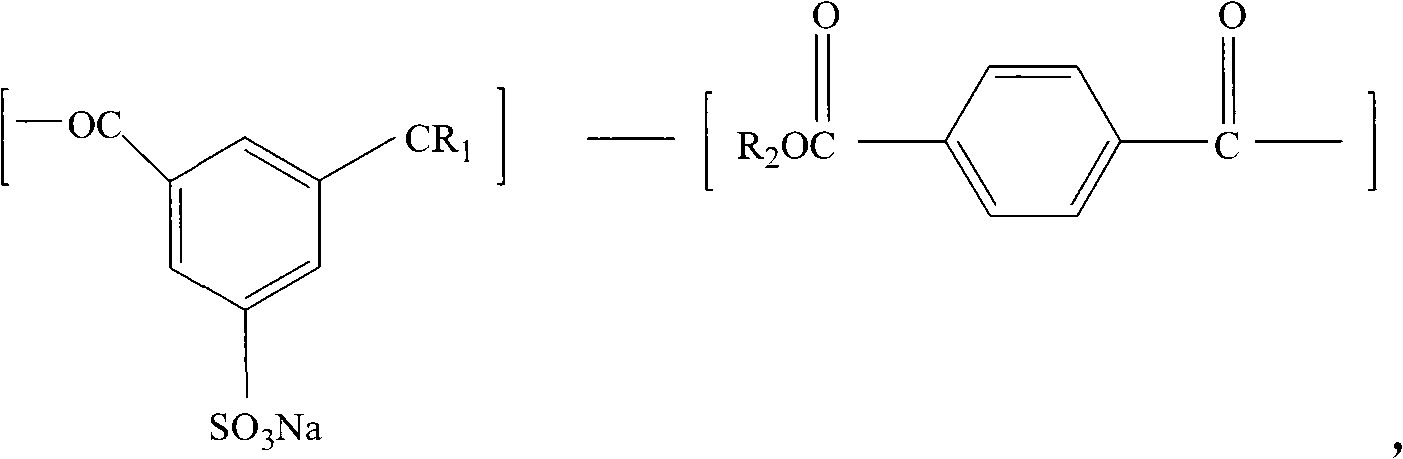

The invention provides a nano silver dispersion comprising sulfonate base water dispersible polyester which is a random copolymer with the molecular formula as follows: R1 or R2 independently comprises OCH2CH2, OCH2CH2CH2CH2 or nano silver solution. The invention also provides a jet printing ink comprising the nano silver dispersion.

Description

Nanometer Silver Dispersion Liquid and Its Jet Printing Ink technical field The invention relates to a nano-silver dispersion liquid capable of uniformly dispersing nano-silver, and in particular to a jet printing ink containing the nano-silver dispersion liquid, which has good electrical conductivity and strong adhesion to substrates. Background technique Since the printing preparation process has the advantages of energy saving and material saving, it is currently being actively developed to replace such as optical filters for LCDs, brightening diffusers for LCDs, transparent electrodes for photoelectric components, printing photoresists for PCBs, The yellow light lithography preparation process of today's electronic / optoelectronic industry such as LED chip packaging. Moreover, if the silver wires can be formed by the jet printing preparation process, it will bring greater benefits to the industry, and the most important key material of this preparation process is conduc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08J3/03C08L67/00C09D11/10C09D7/12C09D5/24C09D11/52

Inventor 张信贞钟升峰吴凤美徐美雯潘秋林黄尔培

Owner IND TECH RES INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com