Insulating sleeve for oil filling

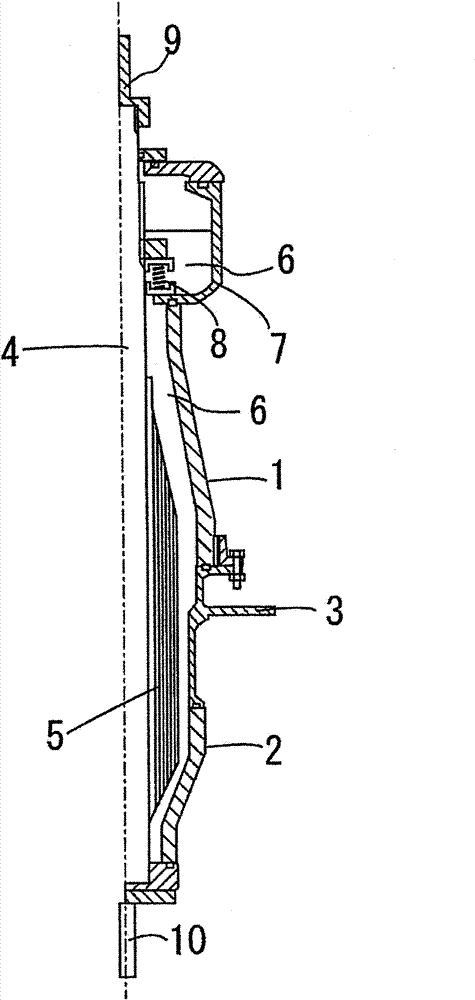

An insulating sleeve, oil-insulated technology, applied in insulators, electrical components, circuits, etc., can solve the problems of difficult to deal with quality management, cannot be ensured frequently, temperature rise, etc., to improve the connection operability and suppress overheating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

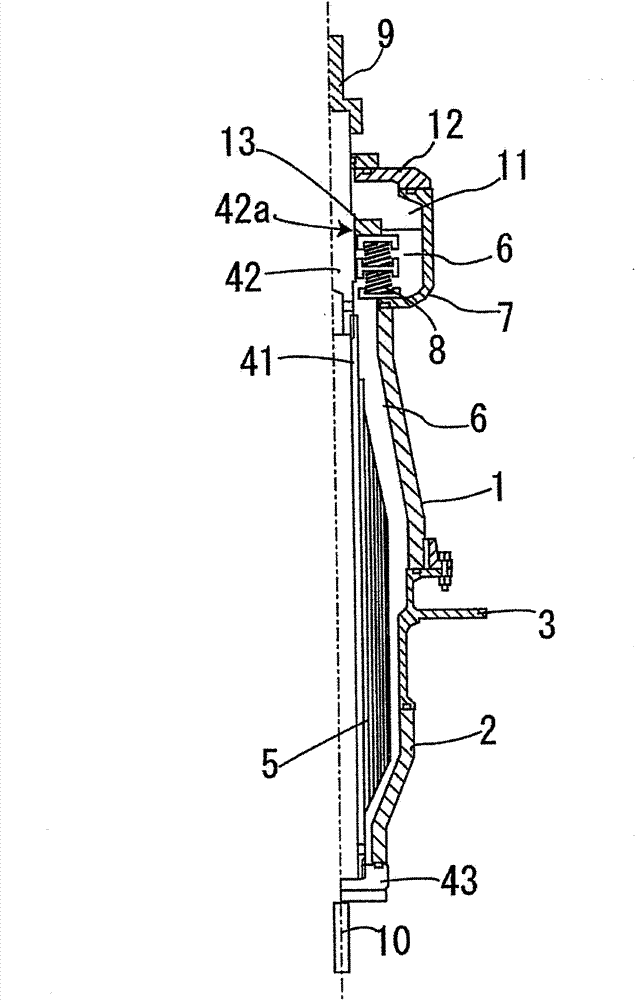

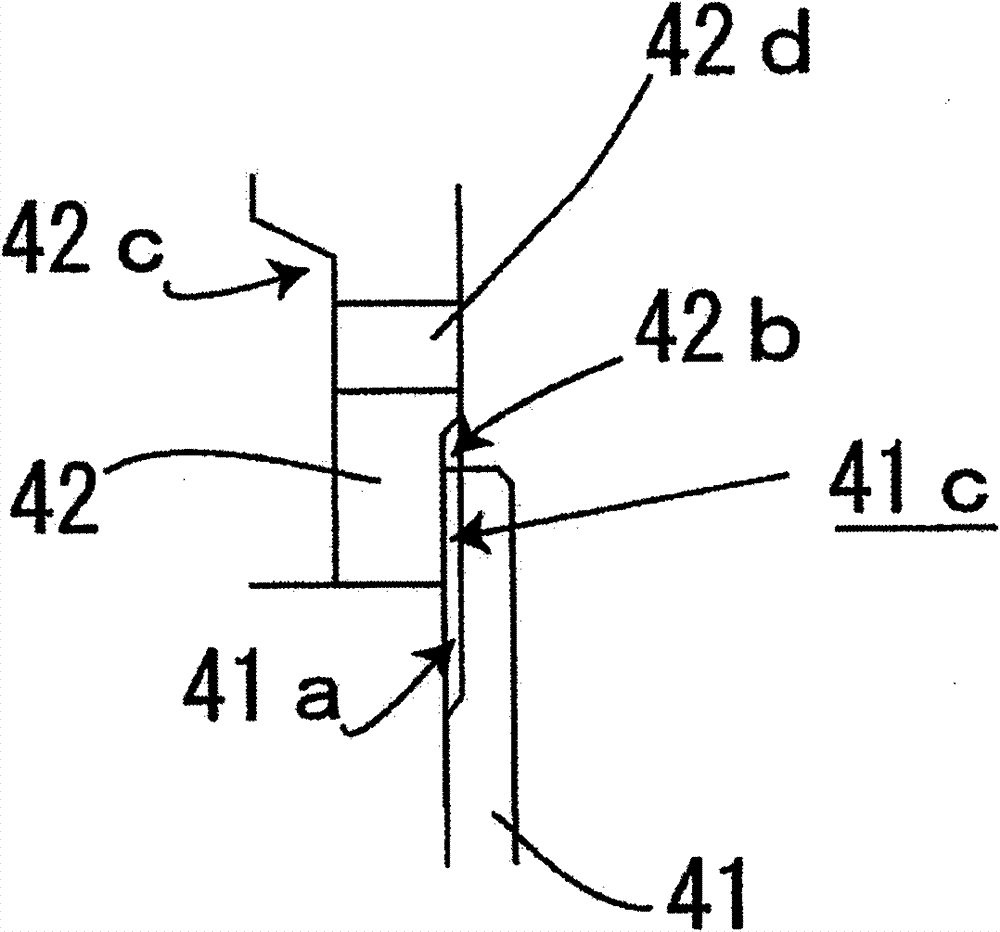

[0064] Figure 5 An explanatory cross-sectional view showing an oil-filled insulating bushing according to another embodiment of the present invention. Figure 6 show Figure 5 An enlarged explanatory view of the threaded connection portion of the central conductor trunk 41 and the top conductor 42 for connecting the current-carrying terminals. In the present embodiment, the central conductor trunk 41 and the top conductor 42 for connecting electric terminals are connected through the connecting pipe 14 . The connecting pipe 14 may be made of copper or aluminum alloy. The upper bolt part 14a of the connection pipe 14 is screwed and connected to the bolt part 42b provided at the lower part of the top conductor 42 for electric terminal connection. The lower bolt portion 14b of the connection pipe 14 is screwed and connected to the bolt portion 41a provided on the upper portion of the central conductor trunk 41 .

[0065] A convection hole 14c is provided near the central hei...

Embodiment

[0068] In the present invention, the upper and lower ends of the central conductor trunk 41 are connected by threading. This connection has excellent mechanical properties compared to other methods of joining by melting metal surfaces such as arc welding or friction welding. That is, this is because since no heat is applied to the material, there is no degradation of the material due to heat. Therefore, when an external force is applied to the insulating sleeve, it has sufficient resistance. Conversely, however, compared with the case of molten metal connection, the bolted connection has a large contact resistance at the joint surface, which has a bad influence of heat generation during energization, and has a great influence especially when a short-circuit current flows through the insulating bushing. If you screw it in normally, just tighten the bolt, and in the tightened state with a normal appropriate tightening torque, a short-circuit current flows. In almost all cases, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com