Axial piston machine in a swash-plate construction with an actuating device

A technology of axial piston and swash plate, which is applied in mechanical equipment, machine/engine, liquid displacement machinery, etc., can solve the problem of increased structural length and achieve the effect of simple assembly and simple assembly

Inactive Publication Date: 2010-08-25

ROBERT BOSCH GMBH

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, if the adjusting piston and counter piston are integrated in the axial piston mechanism, the structural length of the entire mechanism is thereby increased

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

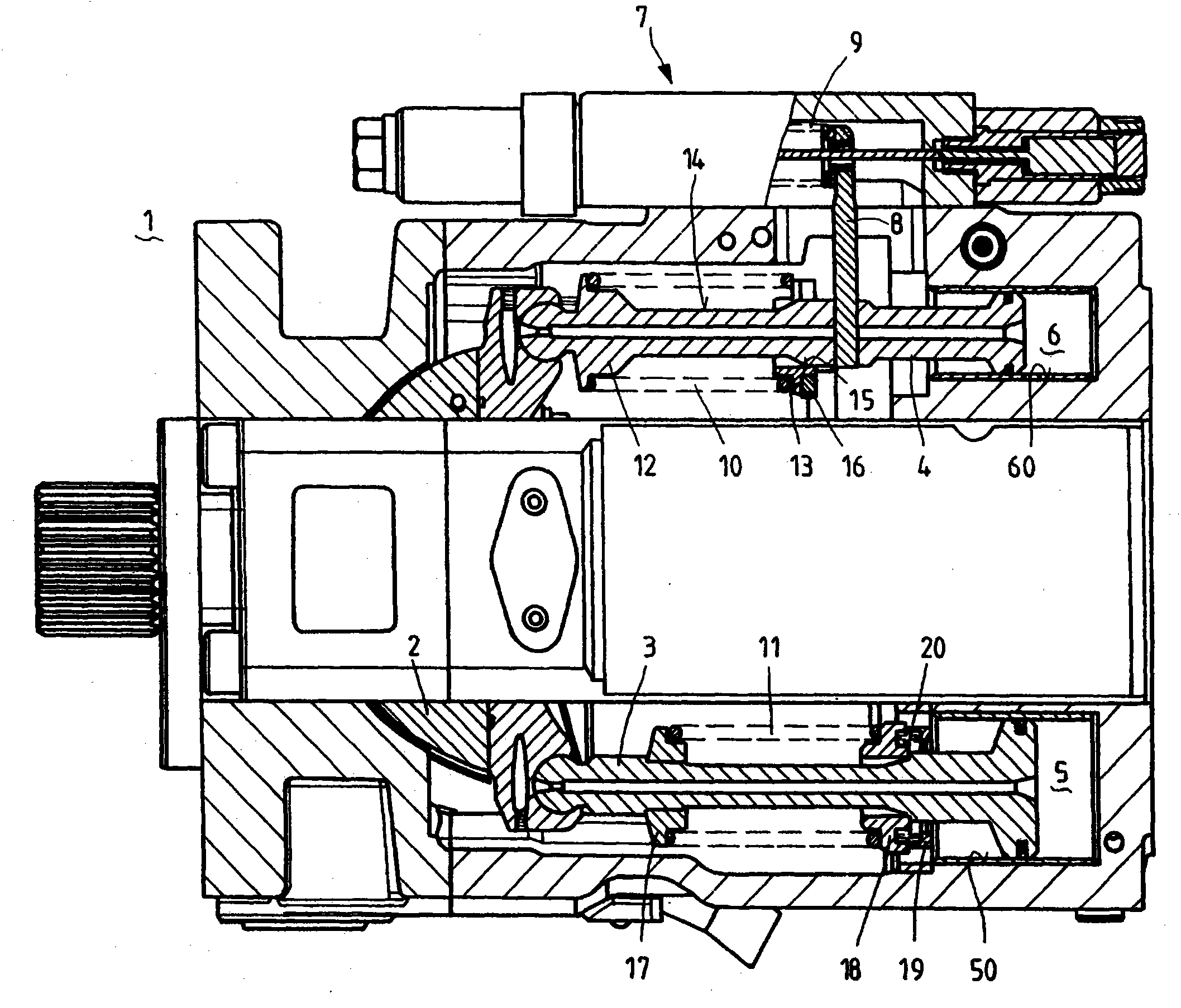

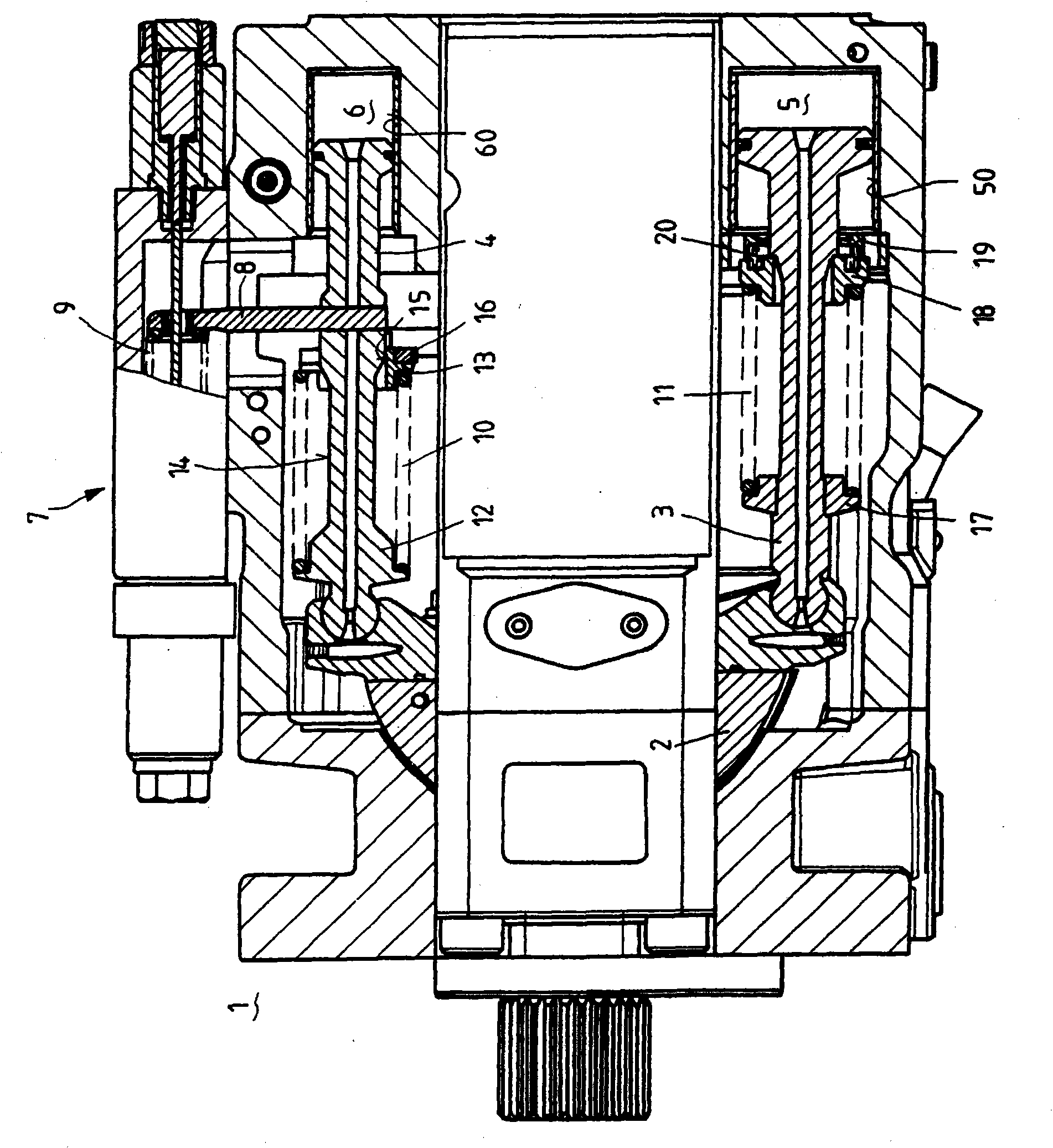

The invention relates to an axial piston machine in a swash-plate construction with an actuating device. The actuating device comprises a actuating piston (3) and a mating piston (4). The actuating piston (3) and the mating piston (4) are connected to the swash plate (2) each with the first end thereof and can be applied with the second end thereof with a force acting in the direction of the first end. For resetting the swash plate (2) in the direction of a resting position, an elastic element (10, 11) is provided on the actuating piston (3) and on the mating piston (4), which is supported on a spring bearing (12, 17) arranged on the first side facing the swash plate (2) of the actuating piston (3) or of the mating piston (4). In the other direction, the elastic element (10, 11) is supported on a second spring bearing (13, 18), arranged on the end facing away from the swash plate (2) of the actuating piston (3) or of the mating piston (4). When the swash plate (2) is deflected from the resting position, the second spring bearing (13, 18) of the actuating piston (3) or of the mating piston (4) is supported on a counter bearing on the housing side. The second spring bearing (13, 18) of the respective other actuating bearing (3) or mating bearing (4) is supported on a counter bearing on the piston side.

Description

technical field The invention relates to an axial piston mechanism in a swash plate configuration with adjustment means. Background technique The axial piston mechanism comprises a plurality of pistons arranged to be longitudinally displaceable within a rotatably mounted drum drum. The pistons are supported on a swash plate or pivot bracket, the angle of inclination of which can be adjusted relative to the axis of rotation of the drum drum. The amount of shift varies according to the angle of inclination. Adjusting means are provided for adjusting the inclination angle of the swash plate. The adjusting device comprises, for example, an adjusting piston for changing the angle of inclination in a first direction and a counter piston for changing the angle of inclination of the swash plate in the opposite direction. In order to reach a defined end position of the swash plate in a system with low pressure and without actuating the actuating device, the adjusting piston and / or...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04B1/32F04B1/20F04B49/00

CPCF04B49/002F04B1/2014F04B1/324F04B2201/12041F04B2201/12051

Inventor 赫伯特·德里赫克莱门斯·克雷布斯蒂莫·纳夫茨

Owner ROBERT BOSCH GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com