Novel ink-jet printing system and matched ink cartridge thereof

An inkjet printing and inkjet printer technology, applied in the field of ink cartridges, can solve the problems that the use of the ink supply pipeline affects the normal operation of the printer, the ink leaks from the ink container, and the printing effect is easily affected, so as to reduce the design and production cost and reduce the production. cost, effect of enhanced adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

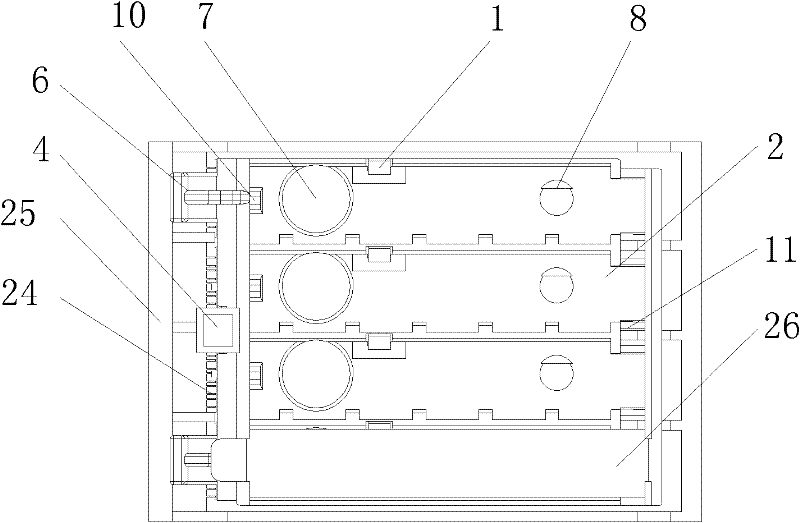

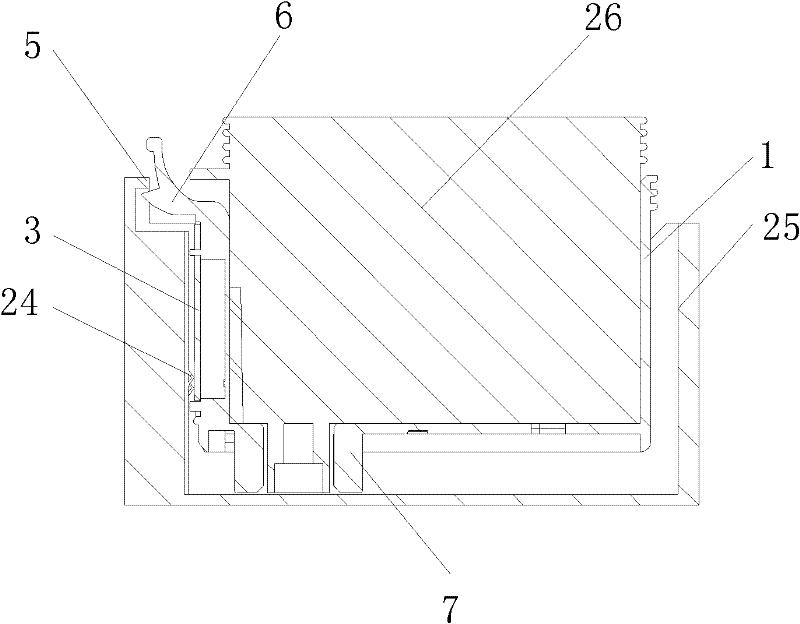

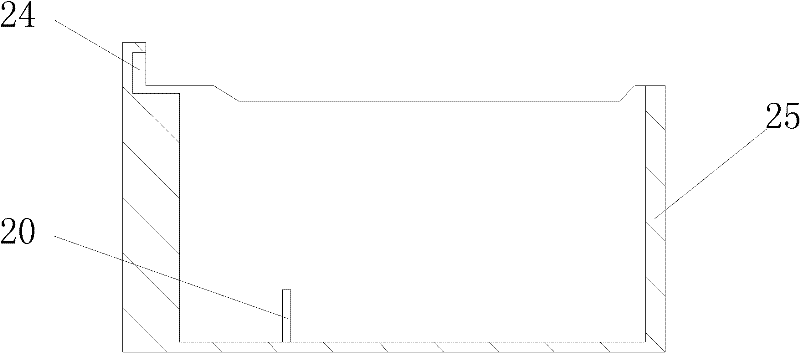

[0026] Such as Figure 1 to Figure 8 As shown, the inkjet printing system described in the present embodiment mainly includes: the ink cartridge frame 1 with the control key conjoined chip installed on the printing carriage 25 in the inkjet printer and the ink cartridge frame 1 used on the ink cartridge frame 1 Ink cartridge 26, four ink cartridge installation positions 2 are arranged in the ink cartridge frame 1, and a chip is arranged on the outside of the ink cartridge frame 1, and the chip is a combination of a PCB circuit board 3 and chip components, wherein the chip components Corresponding to the installation positions of the ink cartridges in the ink cartridge holder 1 respectively, and the number of chip components is the same as the number of ink cartridges installed is four; the chip components include a contact 27 array, the contact 27 array and The positions of the chip probes 24 on the printing carriage 25 are corresponding and in contact with them. The PCB circ...

Embodiment 2

[0030] Such as Figure 9 to Figure 13 As shown, in the inkjet printing system described in this embodiment, six ink cartridge installation positions 2 are arranged in the ink cartridge holder 1, and the ink supply needle interface 7 is a circular tube 19 protruding downwards. A sealing ring 18 is provided inside the round tube 19 . Moreover, the bottom of the ink tank installation position 2 can also be provided with a side wall hook 21 protruding upwards and cooperating with the ink tank, so as to ensure the close contact between the ink tank 26 and the ink supply needle 20 .

[0031] The ink box 26 that cooperates with it, its ink supply port 13 is the opening that is arranged on the lower bottom surface, is provided with sealing film 22 at this opening. The wide side wall is provided with a draw hook interface 23 for cooperating with the side wall draw hook 21 on the ink cartridge holder 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com