Double-lip sealing ring for rotary shaft of air conditioner compressor

A technology for air-conditioning compressors and rotating shafts, which is applied to the sealing of engines, mechanical equipment, and engine components. It can solve the problems of affecting sealing performance, sealing lip tension and shape instability, and short service life. Unstable performance, eliminate single-bias phenomenon, and ensure the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

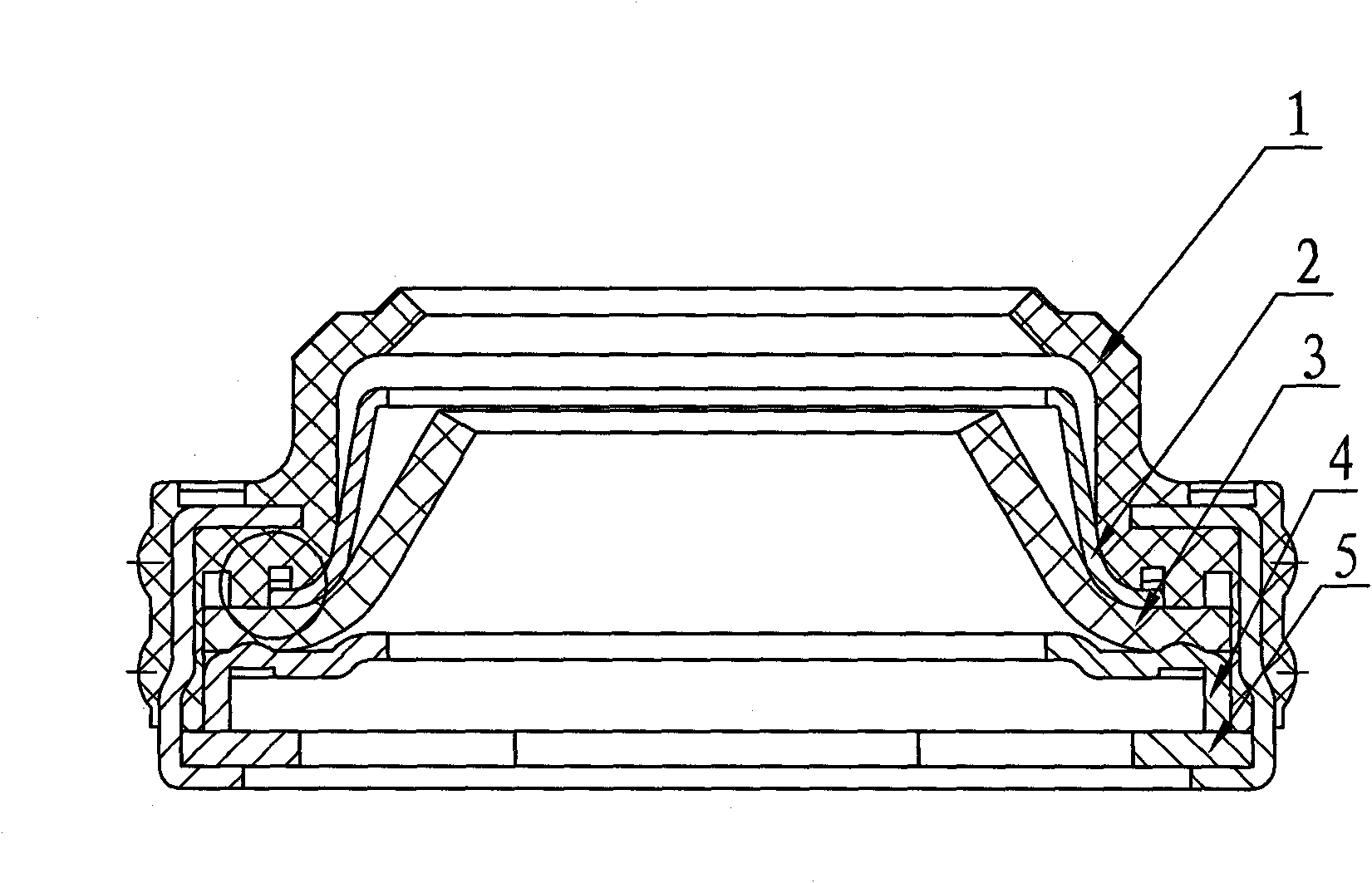

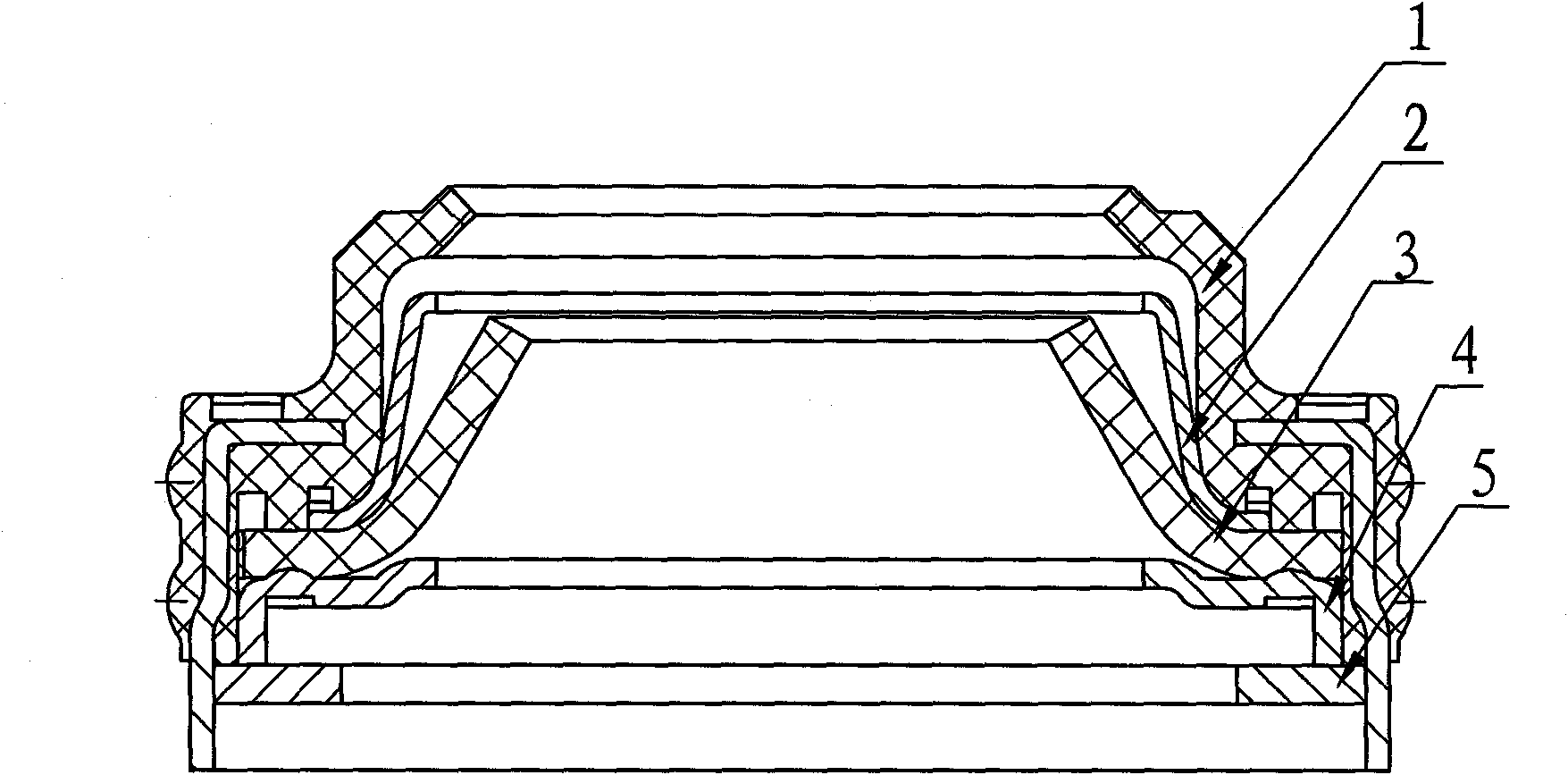

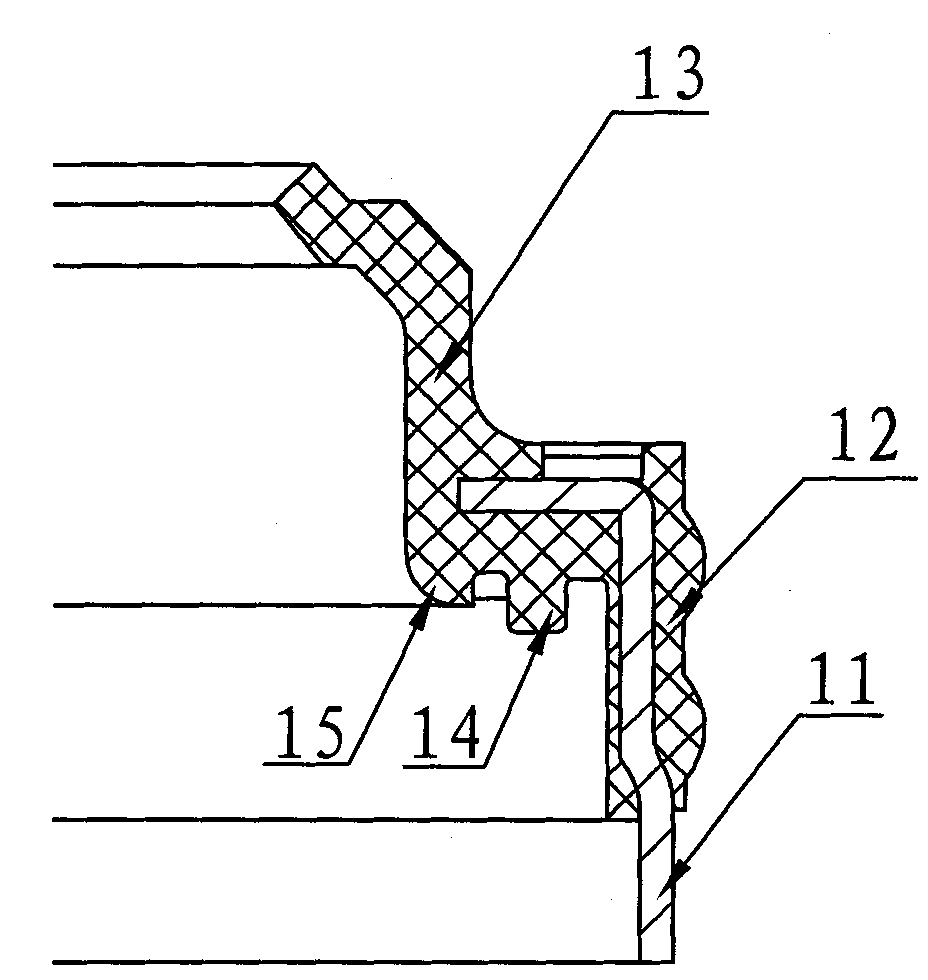

[0014] An air-conditioning compressor rotating shaft double-lip sealing ring, which is composed of a first sealing seat ring 1, a limiting taper sleeve 2, a second sealing ring 3, a pressure-bearing tray 4 and a pressure-bearing washer 5, the limiting taper sleeve 2, The second sealing ring 3, the pressure-bearing tray 4 and the pressure-bearing washer 5 are sequentially installed in the inner cavity of the first sealing seat 1, and are defined by the bending and covering of the outer extension section of the metal skeleton 11; the first sealing seat 1 is composed of metal skeleton 11, rubber outer ring 12, first seal lip belt 13, pressure-bearing boss ring 14, pressure-bearing angle ring 15, outer deformation cavity 16 and inner deformation cavity 17, and limit taper sleeve 2 It is a taper sleeve part with a cross-sectional shape of "eight". The aperture of the small end is matched with the rotating shaft of the air-conditioning compressor. The outer diameter of the large end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com