Detection method used for manufacturing CRTS II type track slabs

A detection method and track plate technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of not fully reflecting the overall rail bearing platform, failing to achieve real-time performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

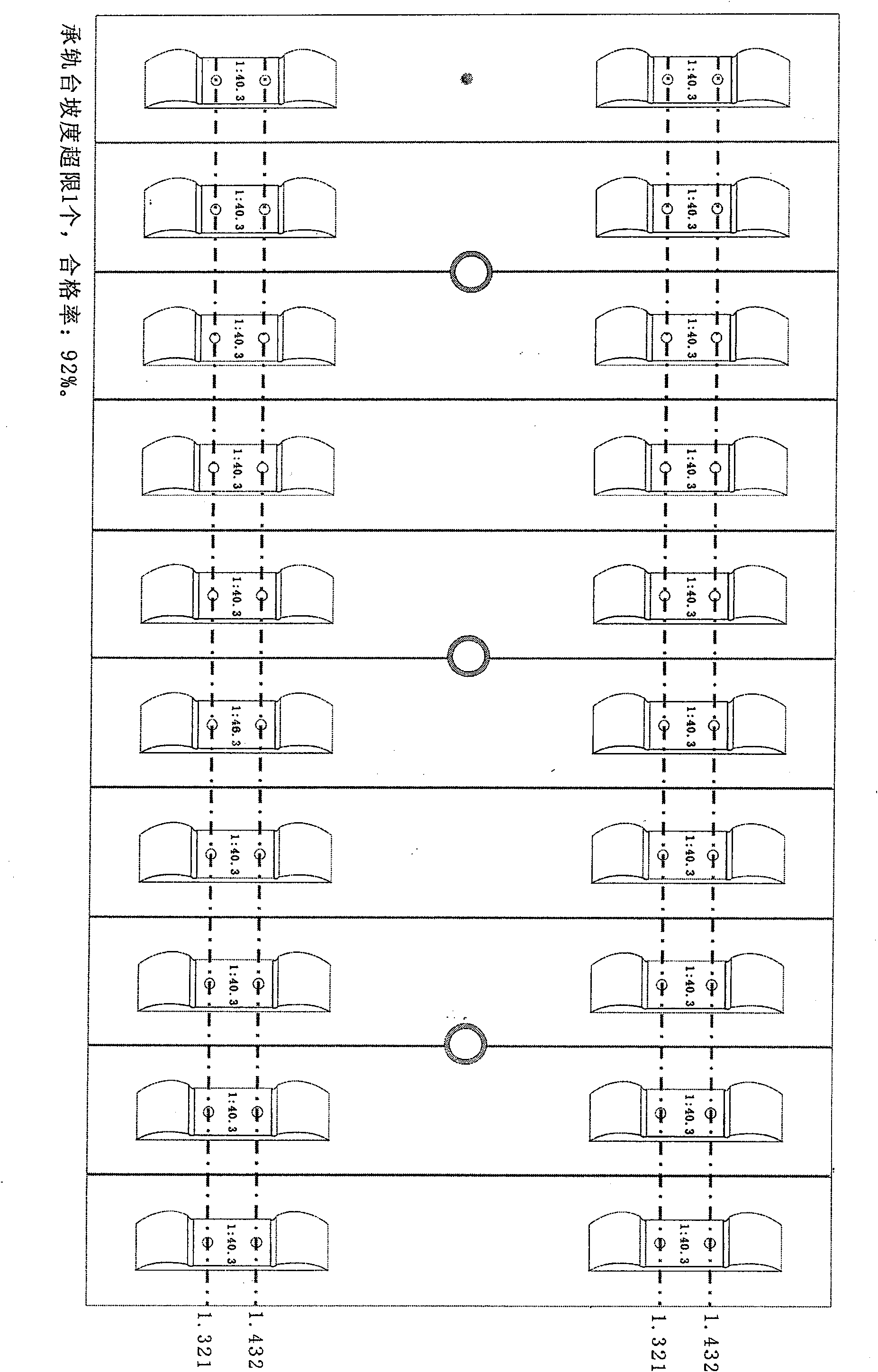

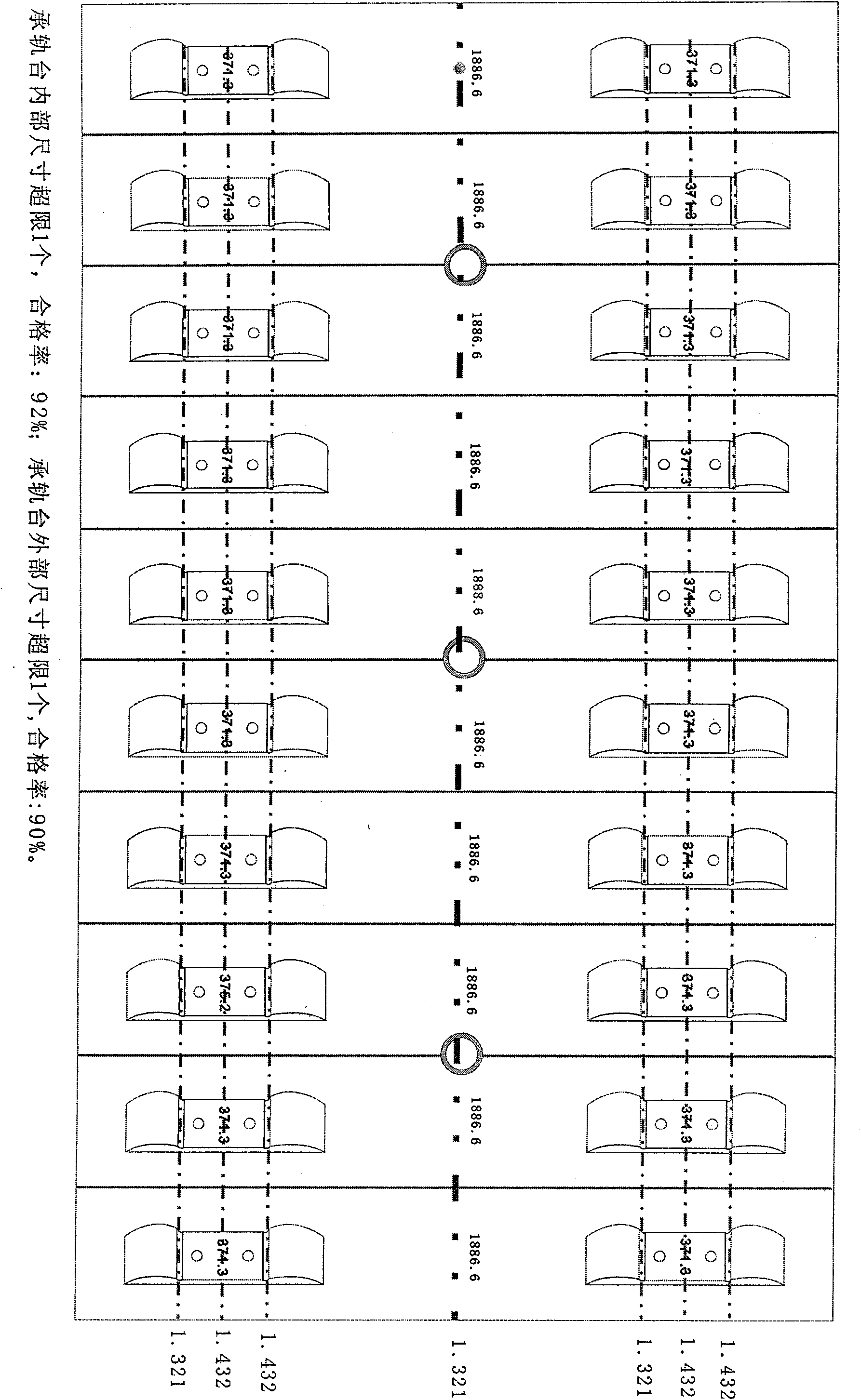

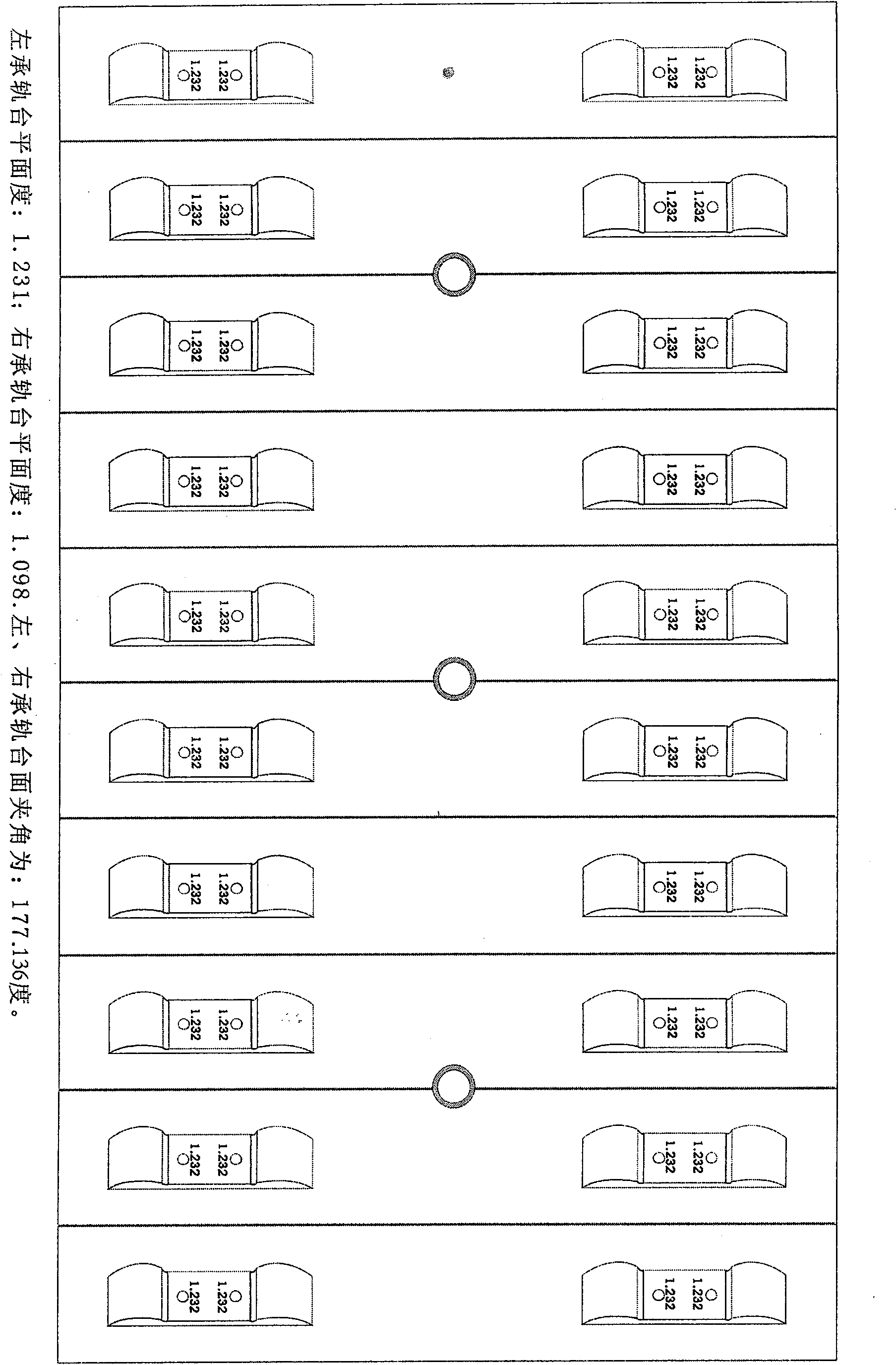

[0057] A testing method for CRTS II track plate making, including the following steps:

[0058] (1) Use TK1, TK2, KUS1 angle magnet block tooling to measure the height and plane adjustment of the tension beam and the adjustment measurement of the oil cylinder

[0059] The installation of the tension beam and the cylinder is the first difficulty in the process of building the factory. According to the "Beijing-Shanghai High-speed Railway CRTS II Track Plate Manufacturing Process Quality Control Manual", it is required that the displacement difference of the jack at the same end during the tensioning process is not more than 2mm, and the jacks at both ends The displacement difference is not more than 4mm. Because a pair of tension beams form a large rectangle with a length of about 65m and a width of 7m, this rectangle cannot be twisted; the forward direction of the oil cylinder must be completely perpendicular to the tension beam, and the step is consistent. The invention adopts TK...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com