A kind of stranding equipment for producing wire and cable

A twisted wire equipment, wire and cable technology, applied in the field of machinery, can solve the problems of product specification and production scale limitation, overall complexity of equipment, poor flexibility, etc., and achieve the effect of convenient operation, good stability, and not easy to mess up the wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

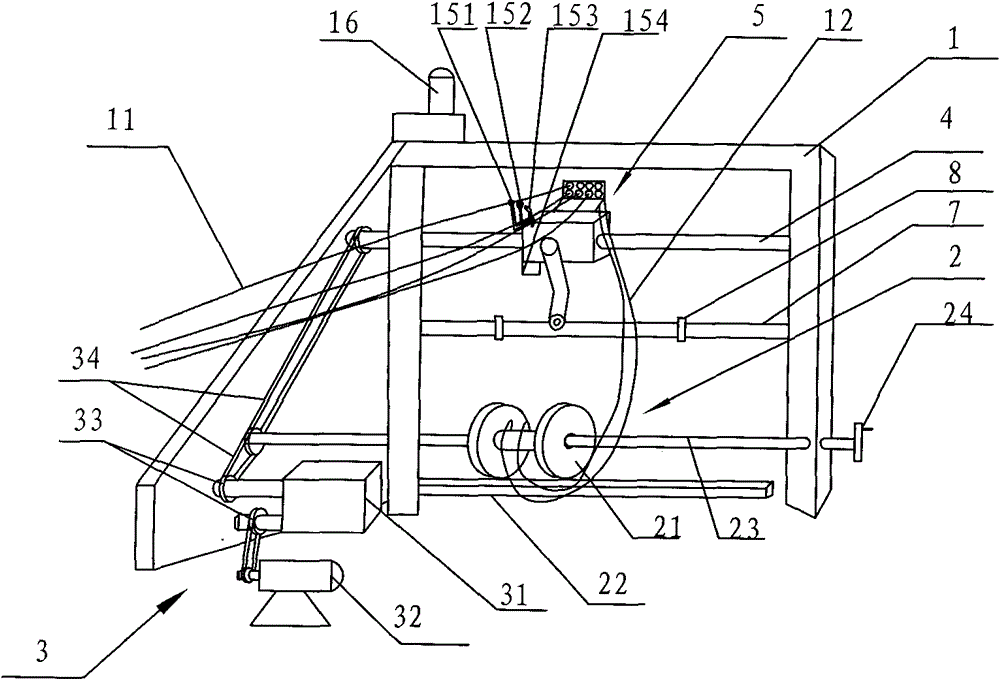

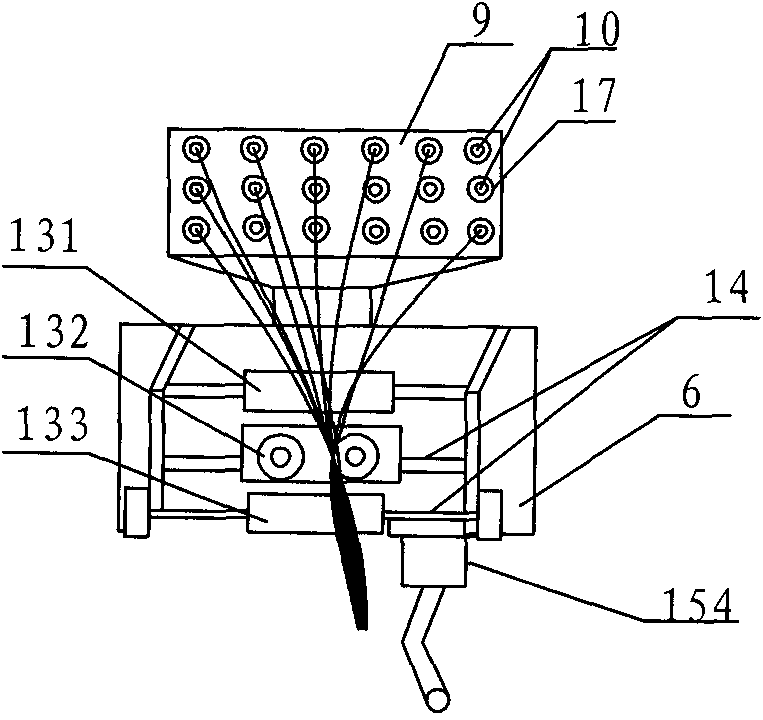

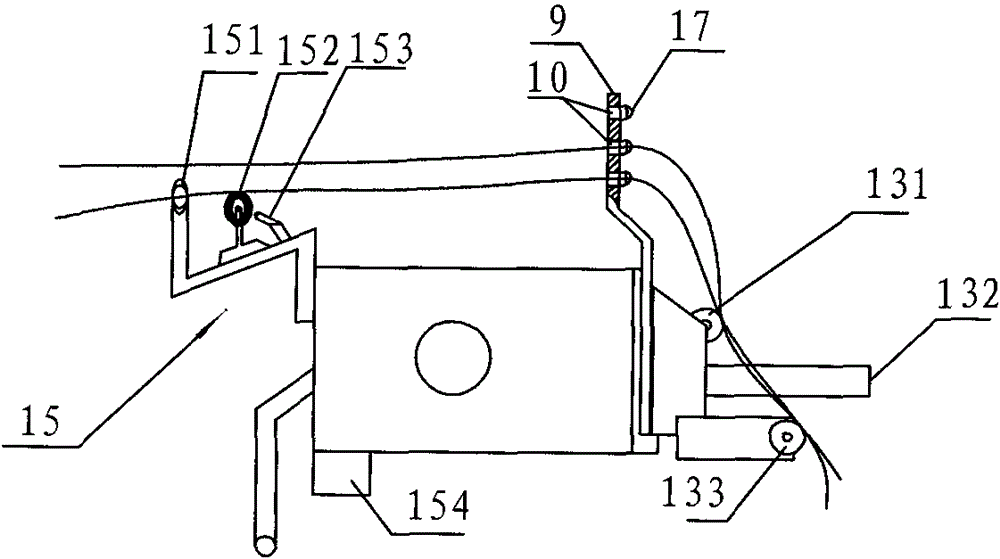

[0019] like figure 1 Said, the present invention is a kind of stranding equipment for producing electric wire and cable, and it comprises frame 1, take-up device 2 and driving mechanism 3, and described take-up device 2 center is provided with a rotating shaft 23, and this rotating shaft 23 and drive The mechanism 3 is connected; a rotating shaft 4 is also arranged on the frame 1, and a twisting device 5 that can reciprocate along the axis of the rotating shaft 4 is arranged on the rotating shaft 4, and is synchronized with the wire take-up device 2 and the driving mechanism 3 through the rotating shaft 4 Mate Motion Connect.

[0020] like figure 1 As shown, the take-up device 2 is made up of an I-shaped wheel 21, a backing plate 22 located at the lower end of the I-shaped wheel 21, a rotating shaft 23 connecting the I-shaped wheel 21, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com