Dynamic sealing device having cooling function for high-power and high-speed submerged motor

A high-speed, electric motor technology, applied in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve problems such as damage, shaft sleeve heating, and leakage of submersible motors, and achieve safe and reliable operation and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

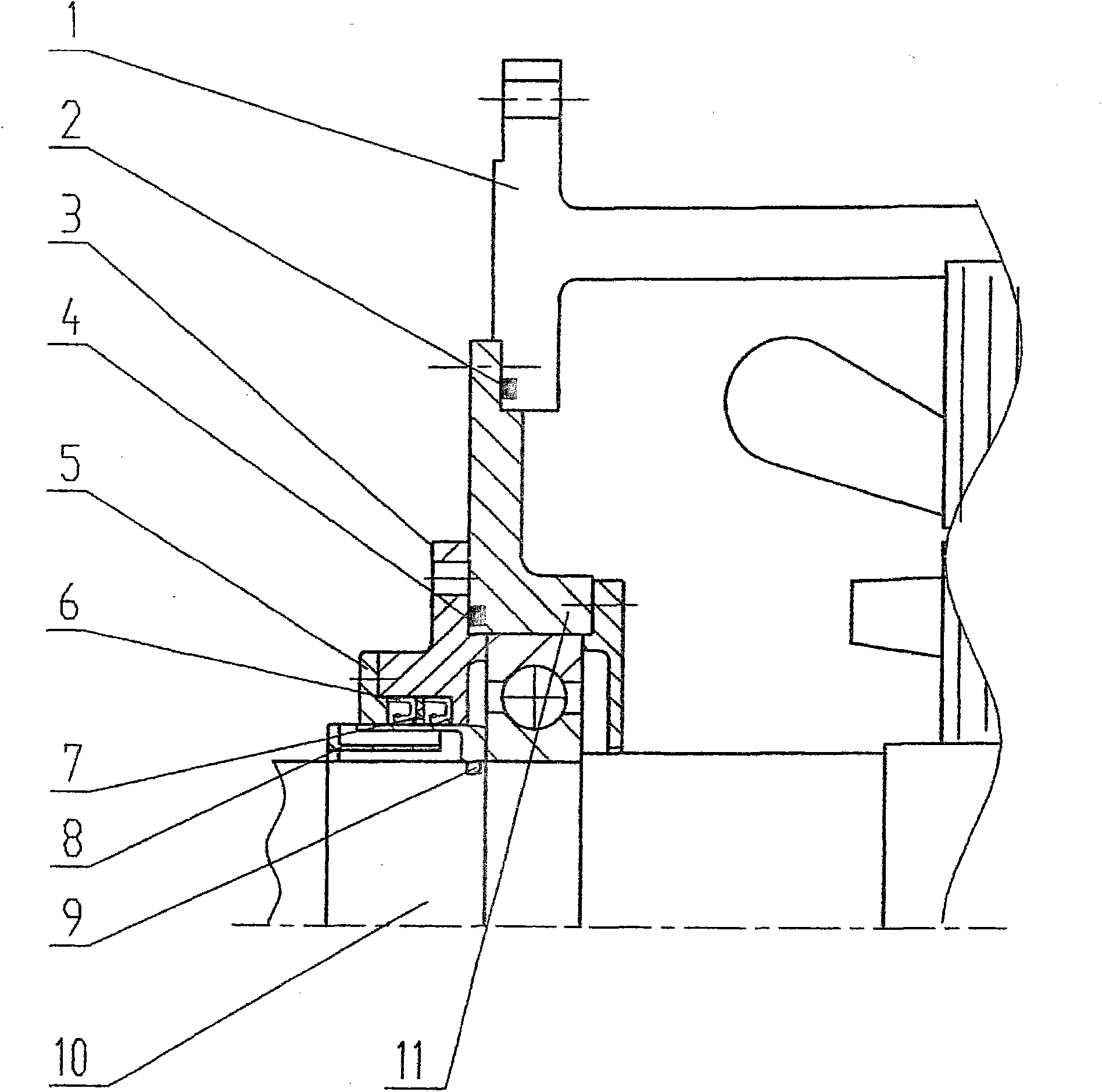

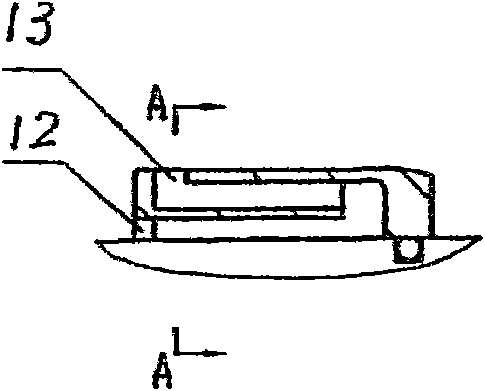

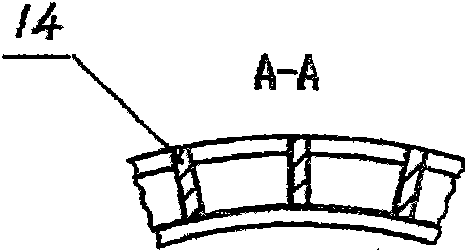

[0013] See attached Figure 1~3 The dynamic sealing device of this high-power high-speed submersible motor with cooling function includes a stator [1], a rotating shaft [10], a shaft sleeve [8] fixed on the rotating shaft [10], and a sealing seat [3] and the shaft sleeve [8] seal, the seal gland [5] presses the skeleton seal [6] into the groove of the seal seat [3], there is a seal ring III [9] between the shaft sleeve [8] and the shaft [10], the shaft The sleeve [8] is a self-circulating cooling structure, the shaft sleeve [8] has a cooling water inlet [12] and a cooling water outlet [13], the shaft sleeve [8] has longitudinally arranged blades [4], and the sealing seat [ 3] is fixed on the end cover [11], and the end cover [11] is fixed on the stator [1]; a sealing ring II [4] is installed between the sealing seat [3] and the end cover [11], and the end cover [11] ] and the stator [1] is equipped with sealing ring I [2]. There is pressing plate [7] in the middle of skeleto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com