Method for processing chute on armature spider of DC motor rotor

A technology of armature bracket and DC motor, which is applied in the field of processing, can solve problems such as motor failures easily, and achieve the effects of improving the tightening state, reducing manufacturing costs, and improving matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical solutions of the present invention, detailed descriptions are given below through specific embodiments in conjunction with the accompanying drawings.

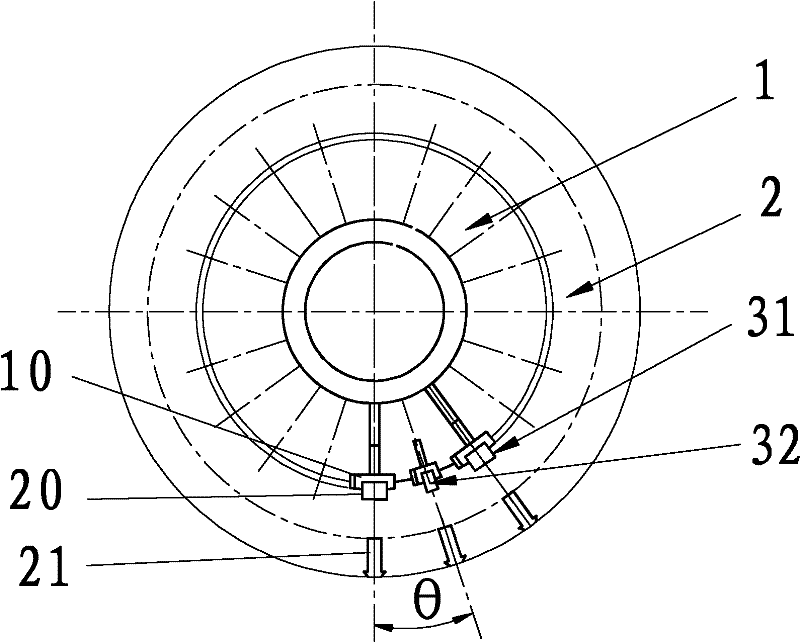

[0021] See Figure 2a with Figure 2b , The method for processing the chute on the armature support of the DC motor rotor of the present invention includes the following steps:

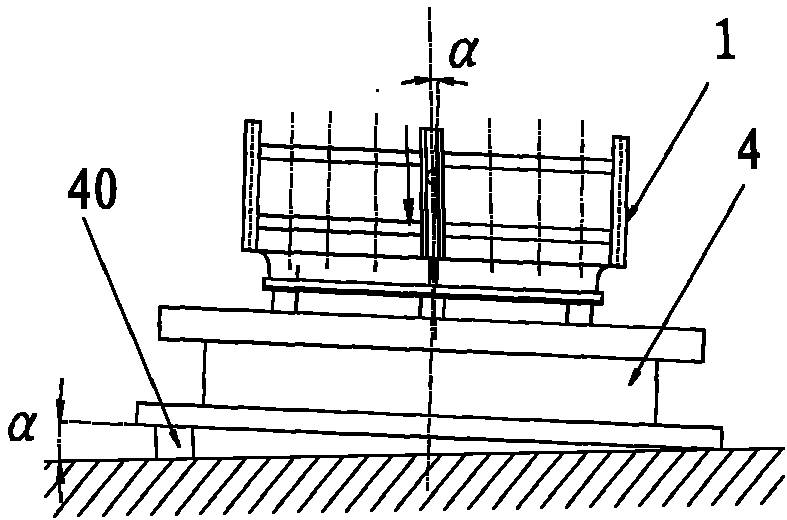

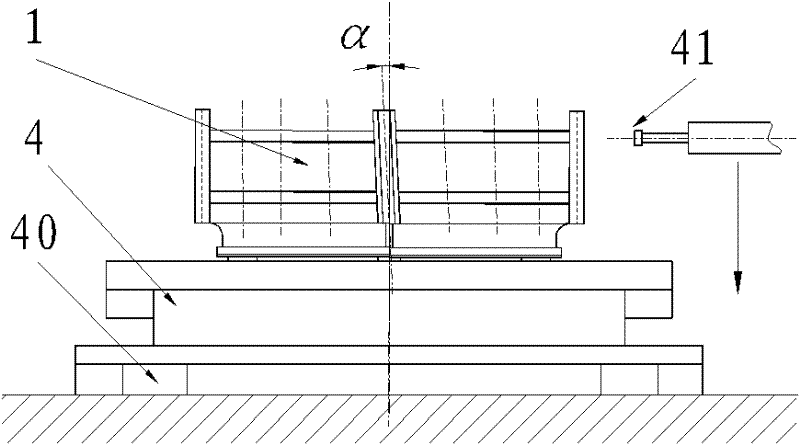

[0022] Step 1: Clamp the workpiece, and fix the armature support 1 on the rotating platform 4 of the boring and milling machine in an upright manner;

[0023] Step 2: Adjust the angle of the rotating platform. Based on the designed angle α between the chute 10 on the armature support 1 and the axis of the armature support 1, a piece of upper end surface and the bottom surface are at an angle on the lower part of the rotating platform 4 Is the cushion 40 of α;

[0024] Step 3: Set the initial zero position of the cutter, and use the axial middle position of the armature support 1 as the calibration reference po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com