Tire

A tire and sidewall technology, applied in special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of rim damage, curb damage, reducing rolling resistance and improving tensile strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0095] The present invention will be described more specifically based on examples, but the present invention is not limited thereto.

[0096]Next, various medicines used in Examples and Comparative Examples will be collectively described.

[0097] Natural Rubber (NR): RSS#3

[0098] Modified butadiene rubber (modified BR): Nipol BR1250H (modified BR, lithium initiator: lithium, tin atom content: 250ppm, Mw / Mn: 1.5, vinyl bond amount manufactured by Nippon Zeon Co., Ltd. : 10 to 13% by weight)

[0099] Butadiene rubber (BR): BR150B manufactured by Ube Industries, Ltd.

[0100] Epoxidized natural rubber (ENR): ENR25 (epoxidation rate: 25% by mole) manufactured by Kunpu Langasuri

[0101] Emulsion polymerized styrene-butadiene rubber (E-SBR): SBR1502 manufactured by JSR Corporation

[0102] Solution-polymerized modified styrene-butadiene rubber (modified S-SBR): HPR340 manufactured by JSR Corporation (bonded styrene amount: 10% by weight, coupled with alkoxysilane, introduce...

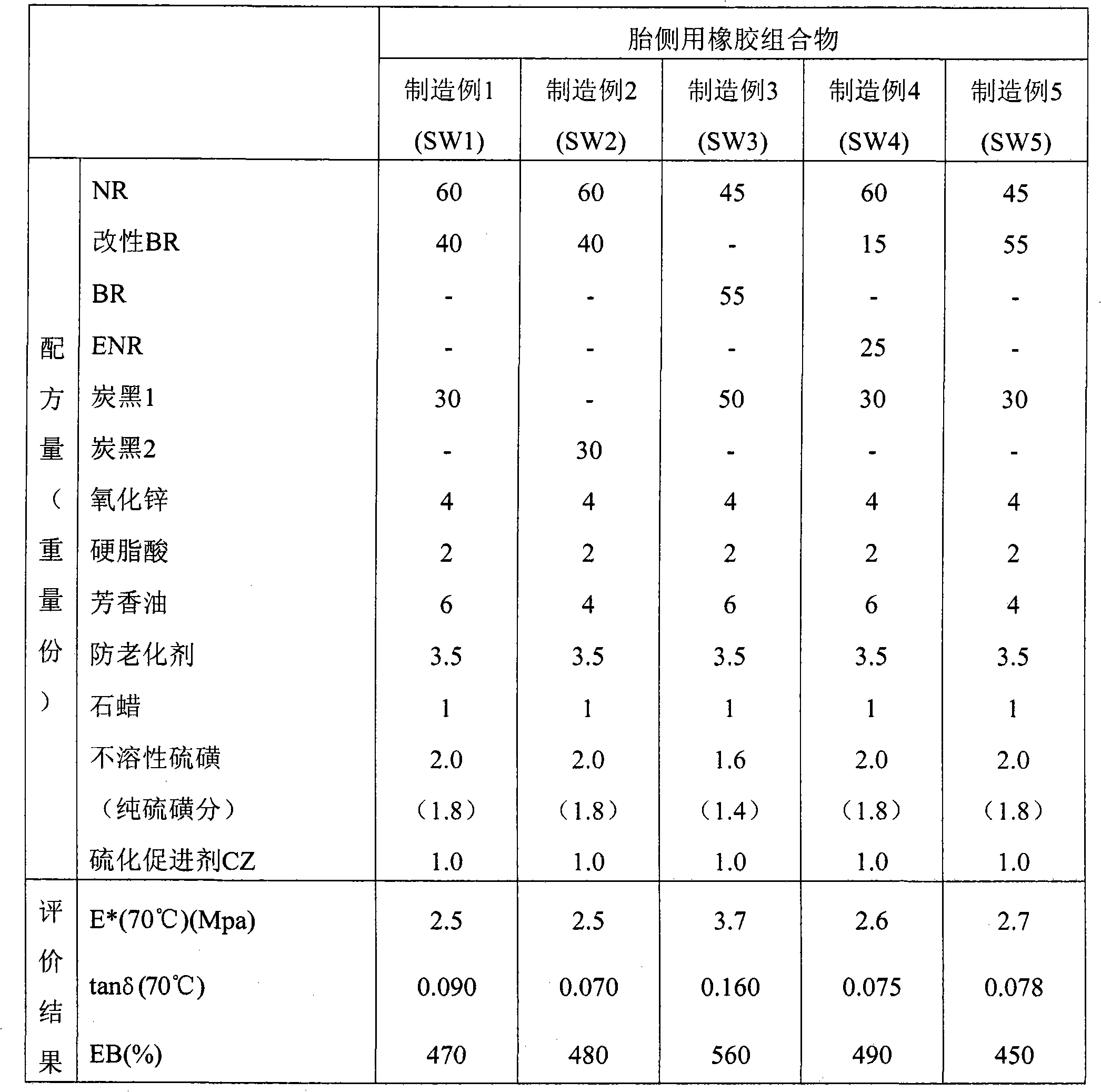

manufacture example 1~5

[0119] Vulcanization accelerator TBZTD: TBZTD (tetrabenzylthiuram disulfide) manufactured by Frekisis Co., Ltd. Production Examples 1 to 5 (rubber compositions for sidewalls)

[0120] According to the formulation shown in Table 1, a Banbury mixer was used to add chemicals other than sulfur and a vulcanization accelerator, and knead at a maximum temperature of 165° C. for 5 minutes to obtain a kneaded product. Then, sulfur and a vulcanization accelerator were added to the obtained kneaded product, and kneaded for 3 minutes at a maximum temperature of 97° C. using two-axis open rolls to obtain an unvulcanized rubber composition. The obtained unvulcanized rubber composition was rolled into a sheet shape in a die, and press-vulcanized at 170° C. for 12 minutes to produce vulcanized rubber sheets of Production Examples 1 to 5 (SW1 to 5).

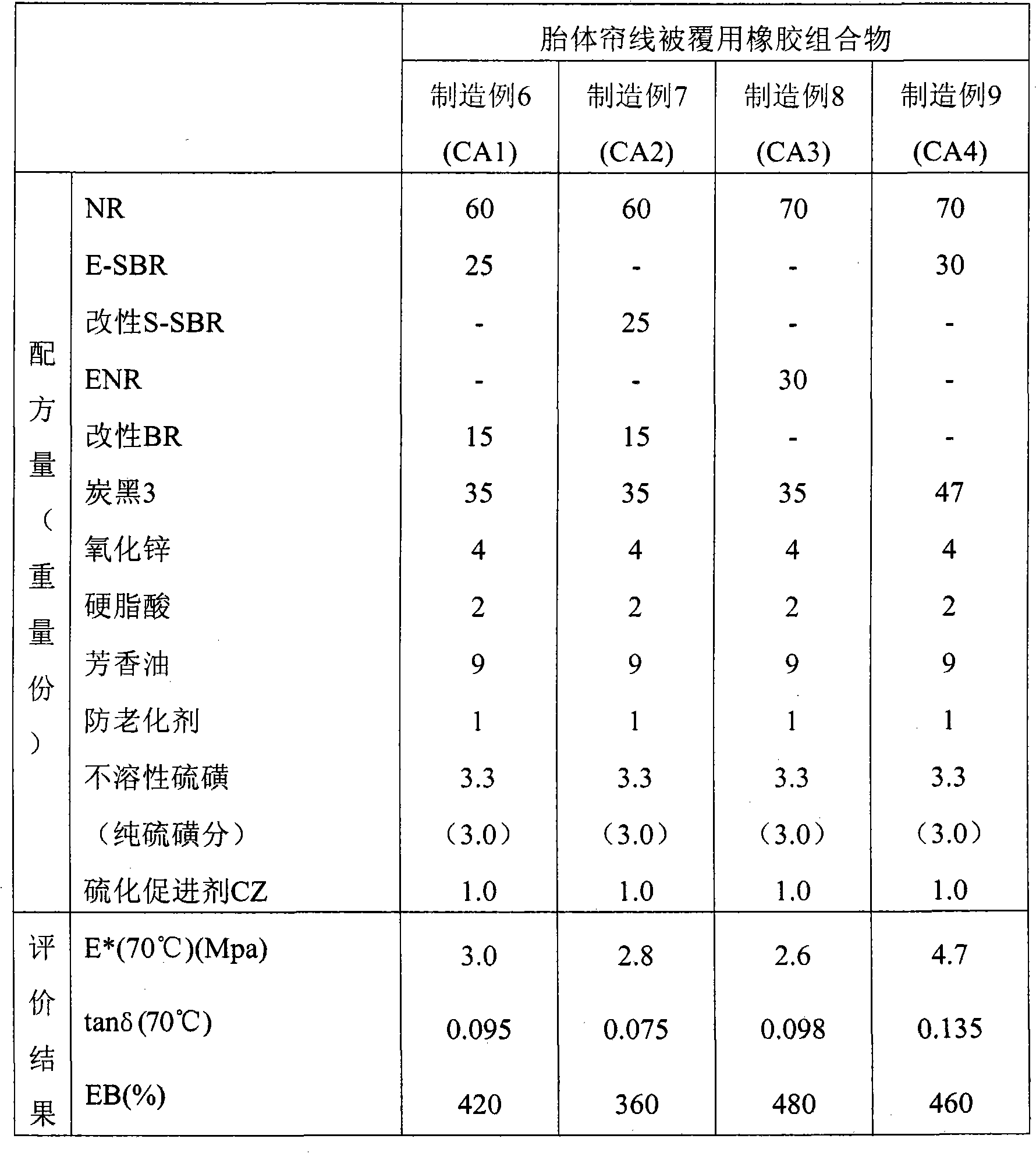

manufacture example 6~9

[0121] Production Examples 6 to 9 (Rubber Compositions for Covering Carcass Cords)

[0122] According to the formulation shown in Table 2, a Banbury mixer was used to add chemicals other than sulfur and vulcanization accelerators, and knead at a maximum temperature of 165° C. for 5 minutes to obtain a kneaded product. Then, sulfur and a vulcanization accelerator were added to the obtained kneaded product, and kneaded for 3 minutes at a maximum temperature of 97° C. using two-axis open rolls to obtain an unvulcanized rubber composition. The obtained unvulcanized rubber composition was rolled into a sheet shape in a die, and vulcanized under pressure at 170° C. for 12 minutes to produce vulcanized rubber sheets of Production Examples 6 to 9 (CA1 to 4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com