Separated transmission mechanisms rotating in different directions

A technology of transmission mechanism and transmission parts, which is applied in sports accessories, indoor games, etc., can solve the problems of increased space occupied by the transmission mechanism, increased motor cost, and increased manufacturing cost, so as to improve the reliability of movement, reduce the number of uses, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

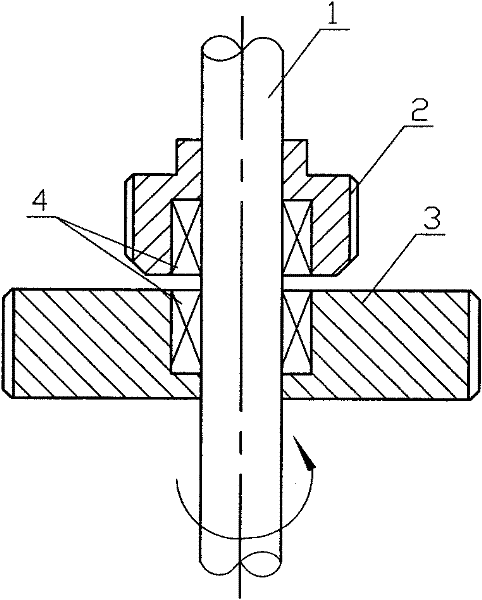

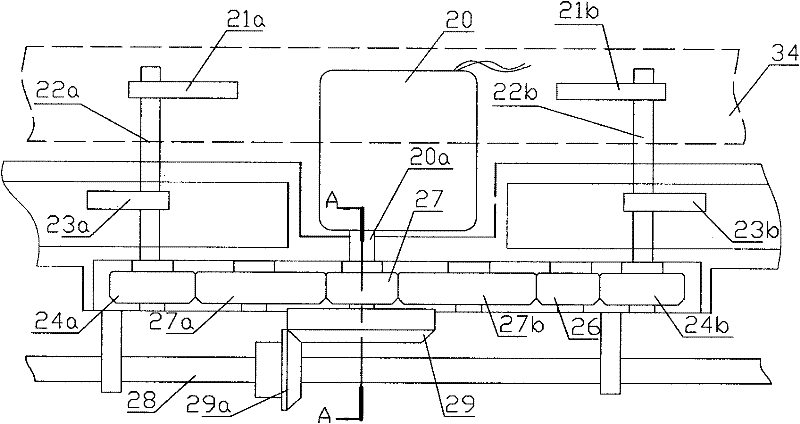

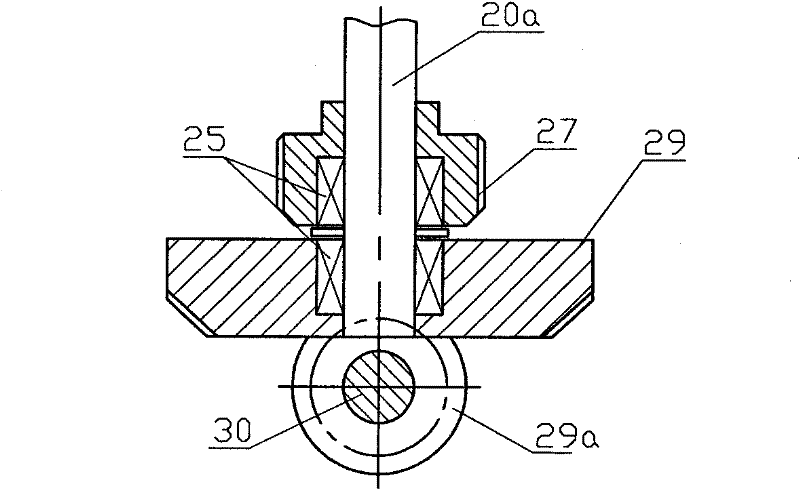

[0018] control figure 1 , the gear transmission part 2 and the gear transmission part 3 are axially installed on the transmission shaft 1 through one-way needle roller bearings, and the two one-way needle roller bearings are placed in opposite directions on the transmission shaft during installation, so that the gear transmission parts 2 and The rotation direction of the gear transmission member 3 is opposite. When the power is transmitted to the transmission shaft 1, the transmission shaft 1 rotates in two different directions, and the rotation of the transmission shaft 1 in each direction will drive the corresponding gear transmission part to follow the rotation through the needle roller in the one-way needle roller bearing. The other gear rotating part does not rotate with the transmission shaft, but produces relative motion with it, so that the rotation of the transmission shaft 1 can be separated by two transmission gears, and the rotation is transmitted to a moving part...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap