Welding structure of small shaft and cover board of electronic expansion valve and electronic expansion valve

A technology of electronic expansion valve and welding structure, applied in the direction of valve operation/release device, valve lift, valve details, etc., can solve the problems of difficult welding positioning, low welding efficiency, inconvenient clamping, etc., and achieve shortening electrode discharge distance, Improve welding strength and solve the effect of insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

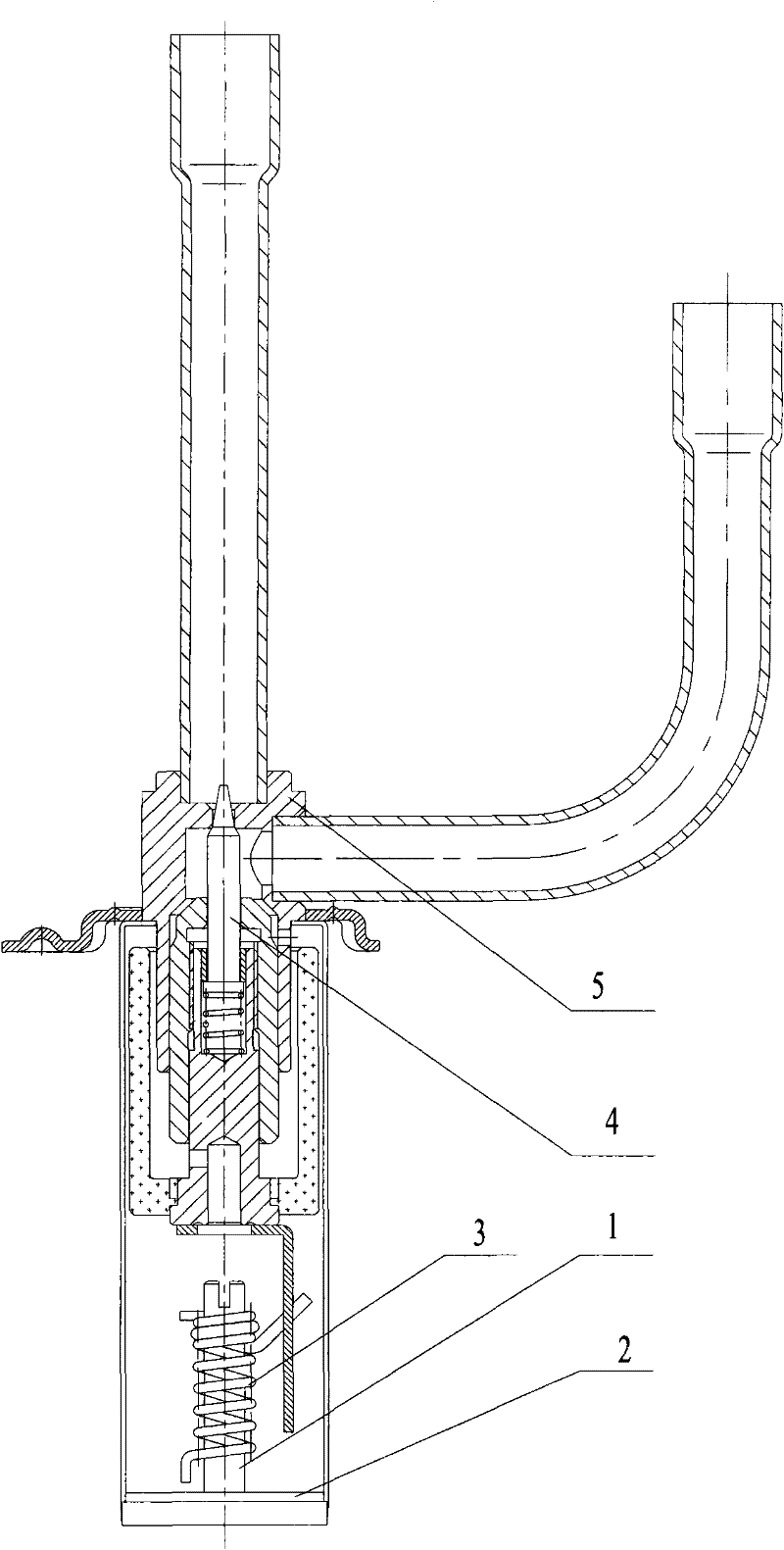

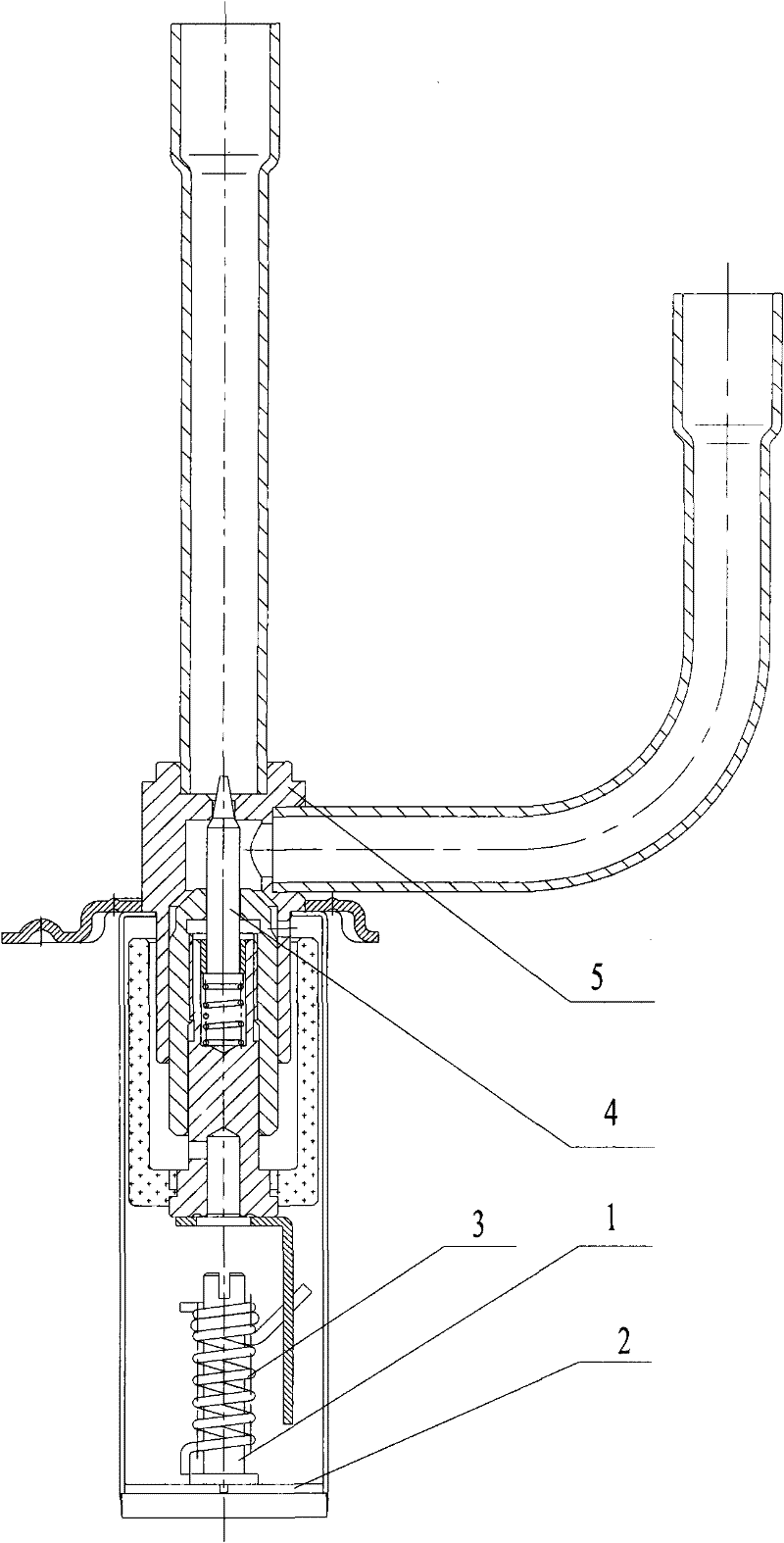

[0037] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

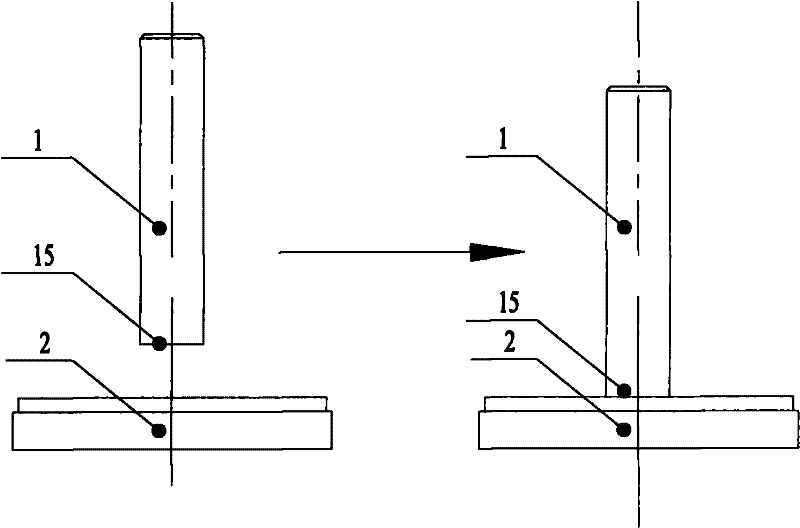

[0038] like Figure 4a as well as Figure 8a , Figure 8b As shown, the welding structure of the small shaft and the cover plate of the electronic expansion valve according to the embodiment of the present invention includes: the small shaft 1 and the cover plate 2 welded together, and the main body of the cover plate 2 is usually a flat plate structure. The welding structure also includes: a positioning structure for enhancing the verticality and welding strength between the small shaft 1 and the cover plate 2 . The positioning structure can be a platform 10 arranged on the welding end 15 of the small shaft 1. During welding, the small shaft 1 is welded on the cover plate 2 through the platform 10; this increases the area of the welding end 15 of the small shaft 1, so it can be Enhance the verticality between the small shaft an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap