Electric furnace load automatic detection recorder

An automatic detection and recorder technology, used in instruments, electric vehicles, measuring devices, etc., can solve problems such as inability to ensure product quality and output, and inability to accurately and quantitatively control process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

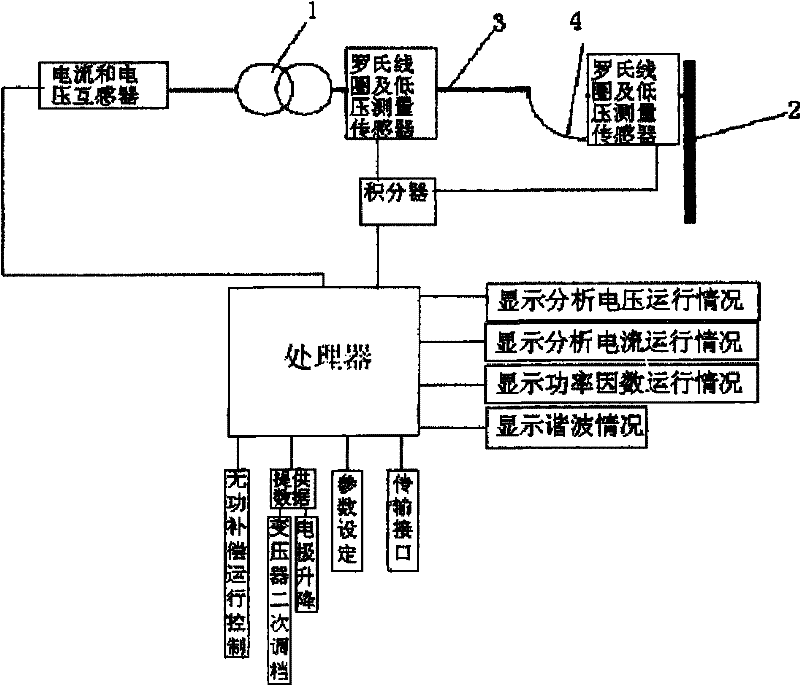

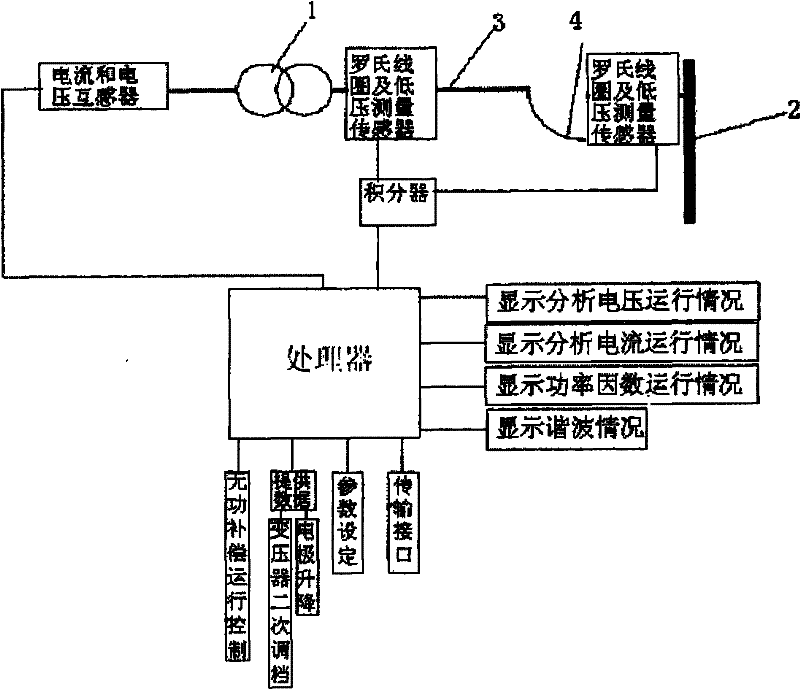

[0011] Such as figure 1 As shown, it shows an automatic load detection recorder for a submerged arc furnace, which includes a voltage transformer, a current transformer, a first Rogowski coil, a second Rogowski coil, a first low-voltage measuring sensor, a second low-voltage measuring Sensors, integrators and processors, wherein the voltage transformer and current transformer are arranged on the primary side (i.e. the high voltage side)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com