Joining structure of sheet-metal components and image forming device

A sheet metal part, combined structure technology, applied in the field of image forming devices, can solve the problems of increased cost and high processing difficulty, and achieve the effect of ensuring grounding performance and solving EMI problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

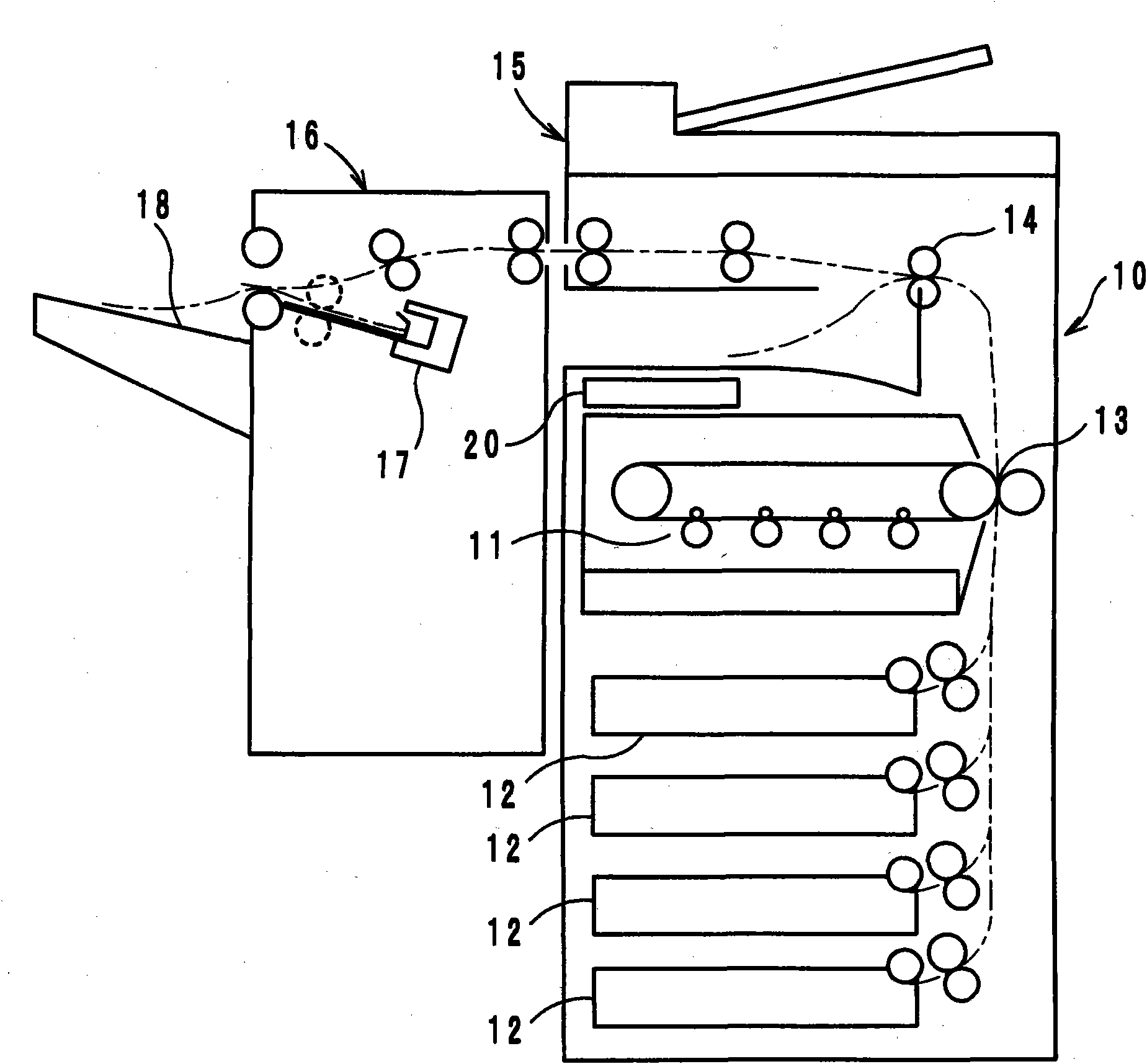

[0030] (for the first embodiment, refer to Figure 2 ~ Figure 4 )

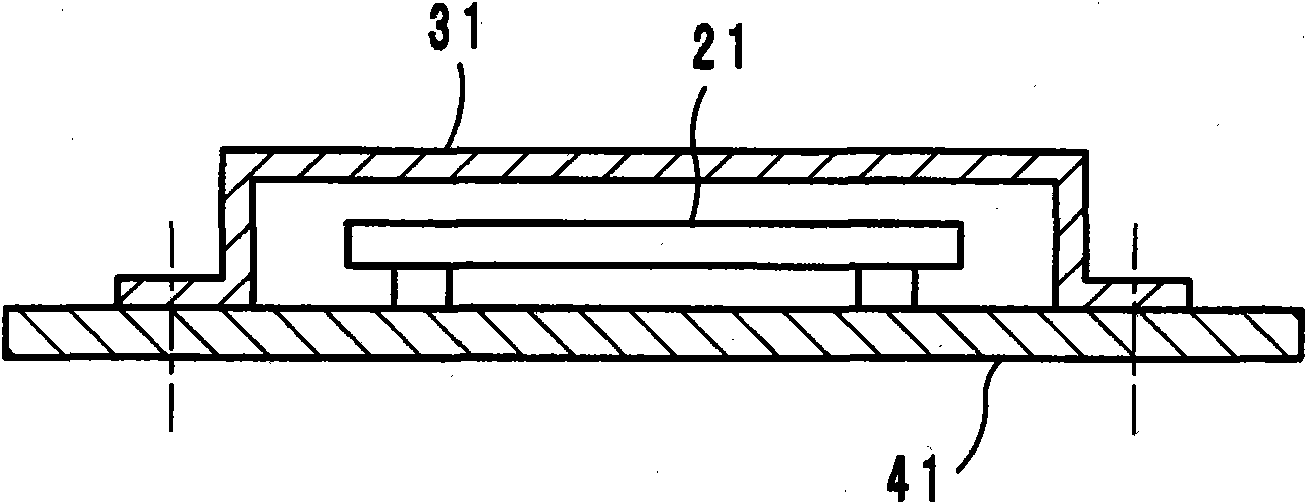

[0031] In the control unit 20, each paper feeding cassette 12, and the finisher 16, etc., a control board is arranged, such as figure 2 As shown, such a control board 21 is mounted on a structural sheet metal part 41 (hereinafter referred to as a second sheet metal part) as a base, and is covered by a shield cover 31 (hereinafter referred to as a first sheet metal part). The joining structure of the sheet metal parts according to the present invention, in the first embodiment, is a structure for joining the first sheet metal part 31 to the second sheet metal part 41 and ensuring an electrically conductive state.

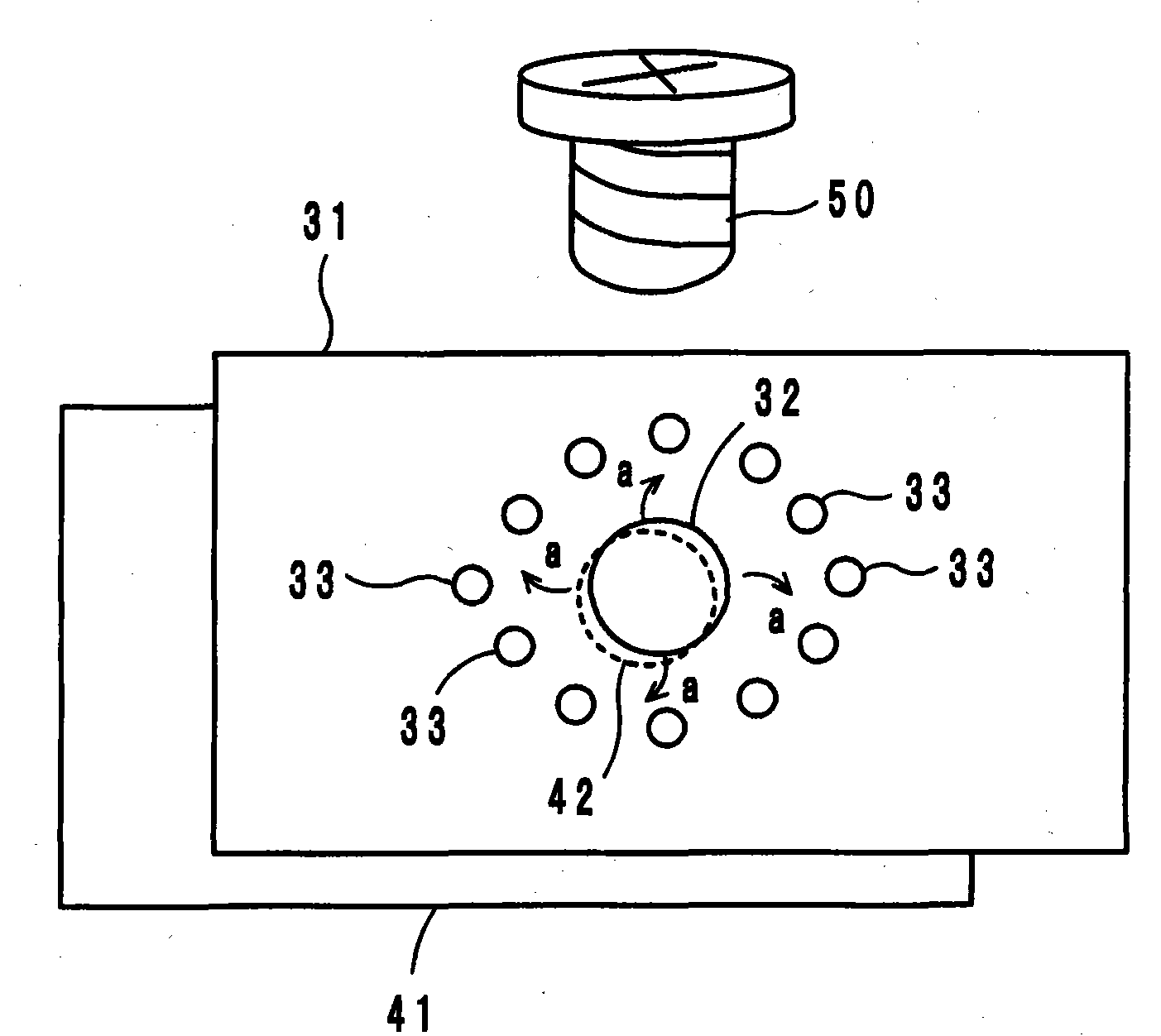

[0032] Specifically, as image 3 As shown, a first pre-hole 32 with a diameter smaller than that of the screw part 50 is formed on the first sheet metal part 31, and a plurality of first pre-holes 32 with a diameter smaller than the first pre-hole 32 are formed around the first pre-hole 32. Small...

no. 2 example

[0036] (Second embodiment, refer to Figure 5 and Figure 6 )

[0037] The combination structure of the second embodiment, such as Figure 5As shown, a second pre-hole 42 having a diameter smaller than that of the screw part 50 is also formed on the second sheet metal part 41 , and a second small hole 43 is formed at a position opposite to the above-mentioned first small hole 33 . The bonding process carried out by the screw part 50 is as Figure 4 As shown, in this second embodiment, since the punching mark of the second small hole 43 is not coated with an insulating resin film, the first and second sheet metal parts 31, 41 are combined. The electrical conduction between the two in the state becomes better.

[0038] In addition, the diameter of the second pre-hole 42 formed on the second sheet metal part 41 is also formed to be smaller than the screw part 50, so when the screw part 50 is used for fastening, the second pre-hole 42 is also formed. deformation force. Under...

no. 3 example

[0041] (for the third embodiment, refer to Figure 9 )

[0042] The combined structure of the third embodiment, such as Figure 9 As shown, knurling is applied to the area 44 facing the first small hole 33 on the bonding surface of the second sheet metal part 41 . Knurling processing is a known processing method in which a knurling tool is mounted on a lathe or the like and rotated to form a desired notch on the surface of an object.

[0043] In the third embodiment, the first small hole 33 is crushed to form a protrusion that is in frictional contact with the knurl forming area 44, so that the first and second sheet metal parts 31, 41 are combined in a good conduction state. .

[0044] (other embodiments)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com