Hole sowing roller device

A drum and hole sowing technology, which is applied to the parts of the seeder and the machine for interval quantitative sowing, can solve the problems of cumbersomeness, inconvenient adjustment of the seed box, and complicated structure of the seed box, and achieve the goal of reducing the void rate and strengthening the strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

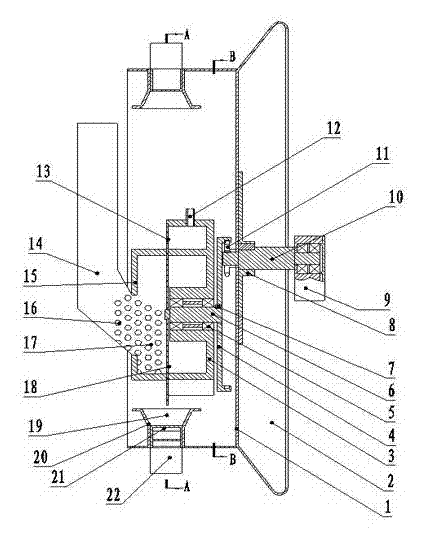

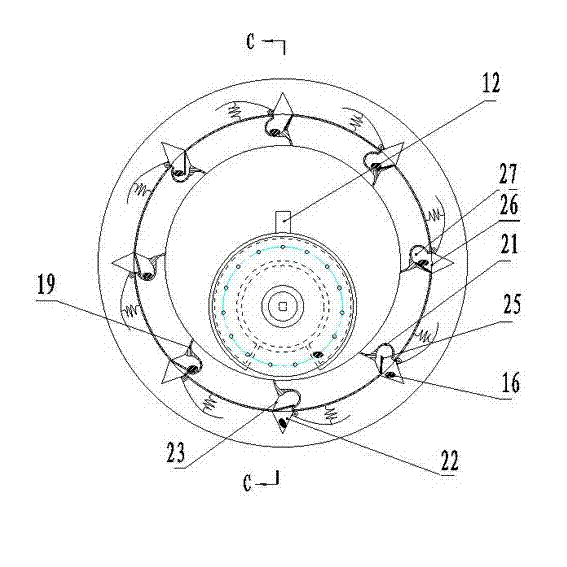

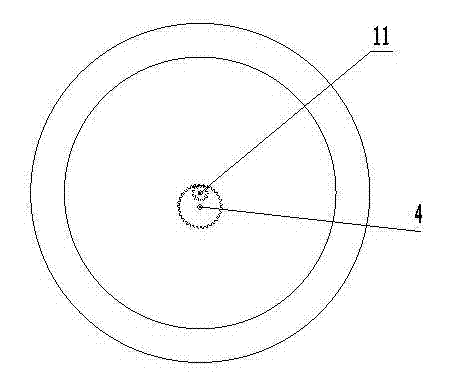

[0014] Such as Figure 1-6 Schematic, the labels in the figure: 1-hole sowing roller, 2-press film wheel, 3-air suction seed divider, 4-driven internal gear, 5-seeder bearing, 6-air suction seed divider main shaft , 7-key, 8-reinforcing disc, 9-traction frame, 10-pit sowing roller main shaft, 11-driving gear, 12-suction pipe, 13-suction hole, 14-seed box, 15-filling seat, 16 -seeds, 17-filling chamber, 18-suction plate, 19-baffle, 20-groove seed delivery channel, 21-seed bin, 22-duck beak, 23-seed hole, 24-hinge shaft, 25 - dodge door, 26 - seed outlet, 27 - storage room.

[0015] The present invention mainly includes a hole sowing drum 1, a duck mouth 22, a film pressing wheel 2, an air suction type seed divider 3, an air suction pipe 12, and a seed box 14. The main shaft 10 is connected with the main shaft 6 of the air-suction type seed divider through gears. It is characterized in that a trough-shaped seed delivery channel 20 is arranged on the inner side of the outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com