Container double side loading and unloading truck

A technology for loading and unloading trucks and containers, which is applied in the direction of vehicles with swing arms, etc. It can solve the problems that containers cannot meet the requirements of road transportation without exceeding the limit, cannot carry out vehicle-to-vehicle loading and unloading operations, and cannot meet the requirements of unfolding outriggers, etc., to achieve flexible turning, Good operation stability, convenient loading and unloading alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific examples.

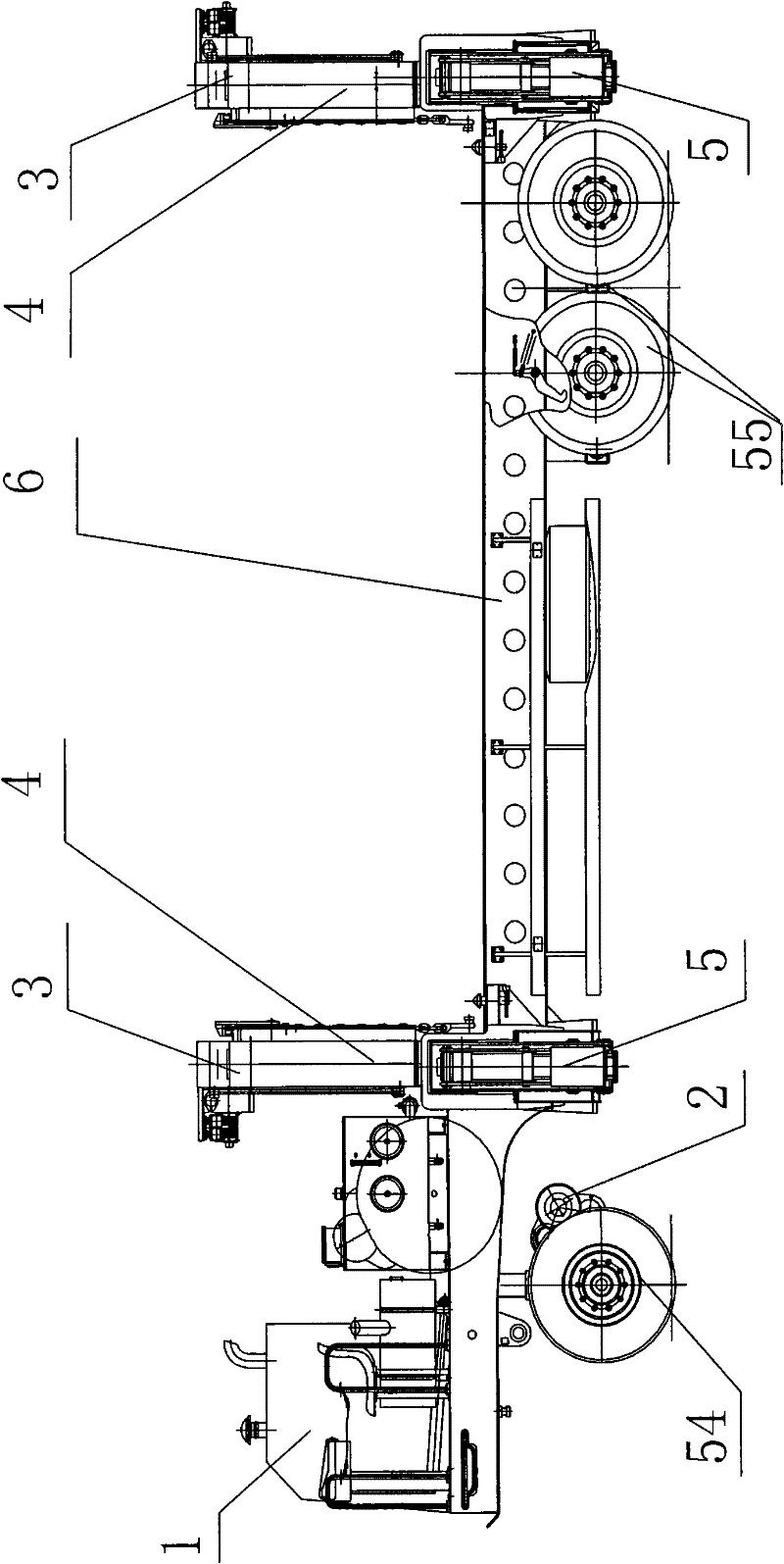

[0028] The overall schematic diagram of the container double-side loading and unloading truck of the present invention is as follows: figure 1 As shown, it includes an engine 1, a hoisting system 3 with the same structure installed at both ends of the vehicle frame 6, a self-propelled system 2, a rear axle and a rear suspension system 55, and the hoisting system 3 is composed of a boom device 4 and a leg device 5. .

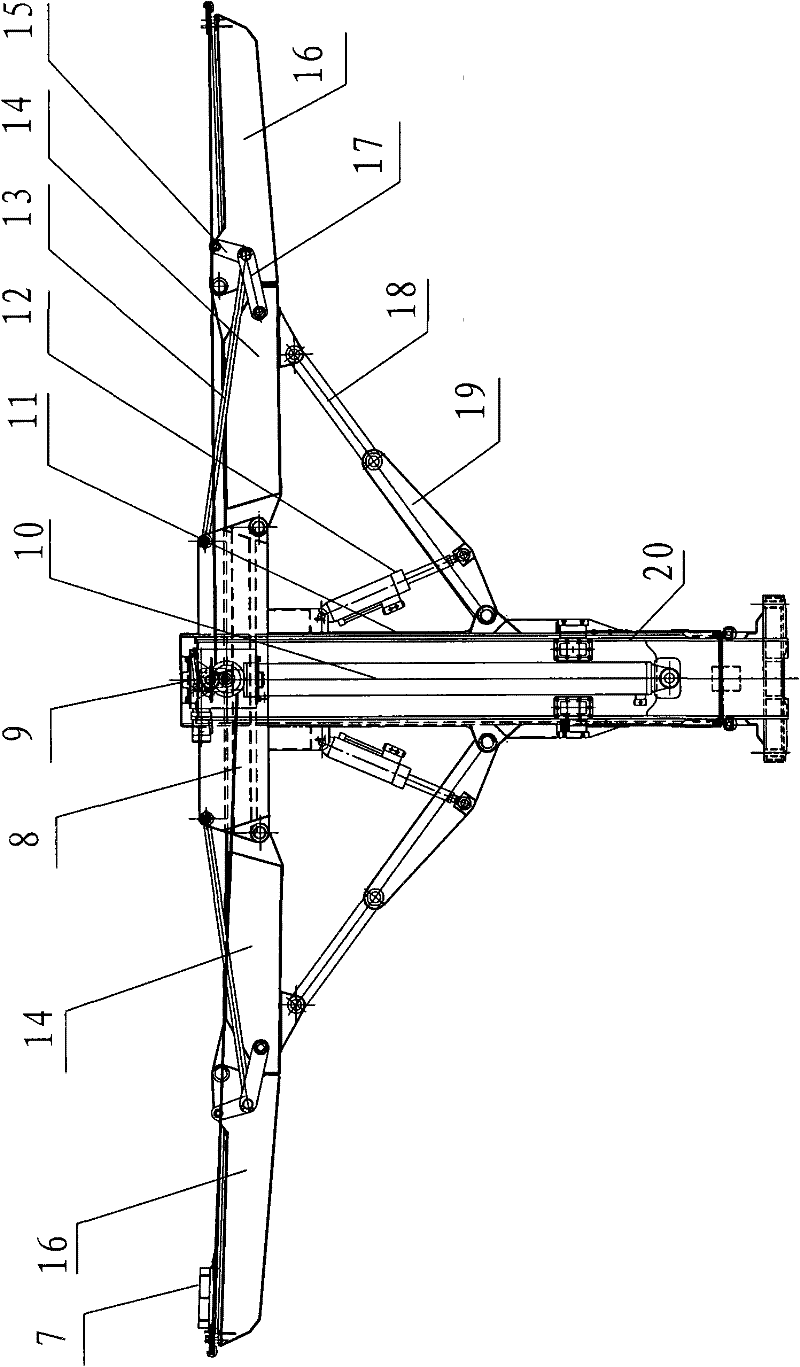

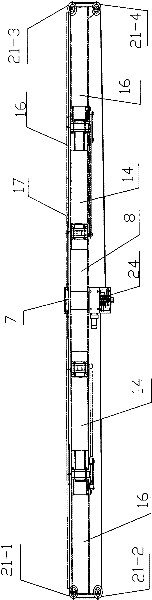

[0029] The schematic diagram of the boom device is as figure 2 with image 3 As shown, it includes a guide post 20 and a T-shaped lifting arm. The vertical part 11 of the T-shaped lifting arm is sleeved on the outside of the guide column 20 and is slidably connected with the guiding column 20, so that the vertical part of the T-shaped lifting arm slides along the guiding column, and the T-shaped lifting arm is connected with the lifting drive mechanism 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com