Universal window wall

A technology of window wall and staggered opening, applied in the field of ever-changing window walls, can solve the problems of thin building glass, difficult fire and disease rescue in the installation of anti-theft barriers, poor anti-theft performance, etc., to increase the anti-load strength and prevent accidental sheet damage. and the risk of ageing of the adhesive, the effect of improving airtightness and watertightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to describe the present invention in more detail, and are not intended to limit the present invention.

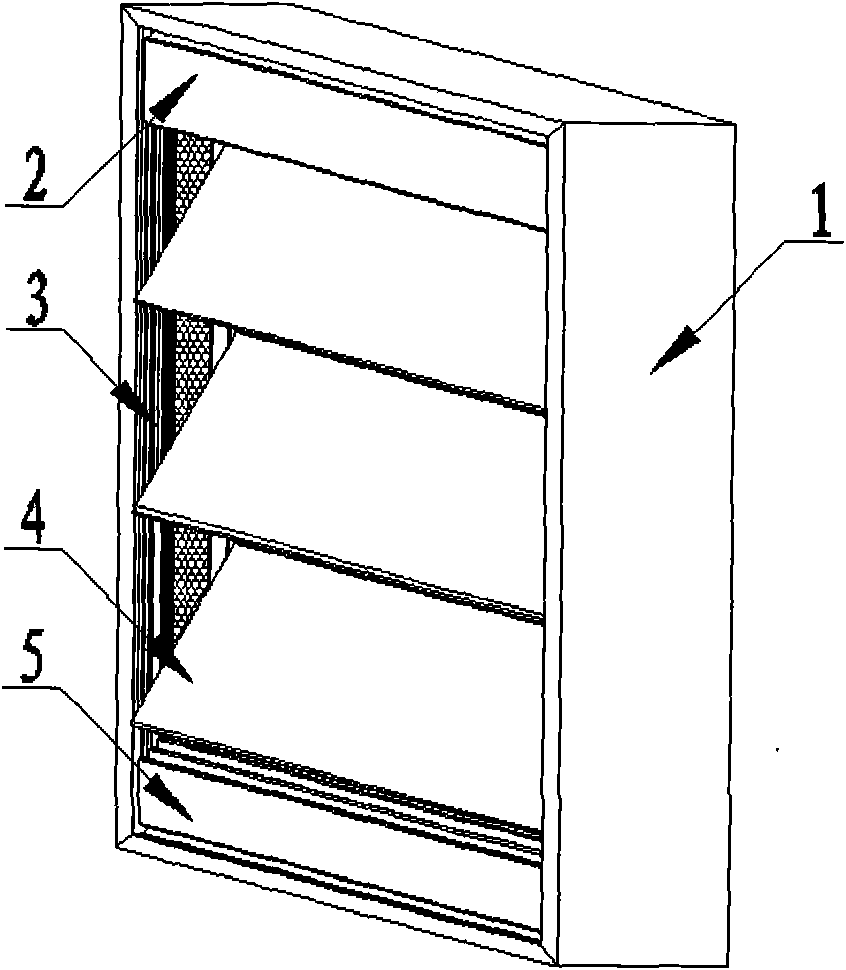

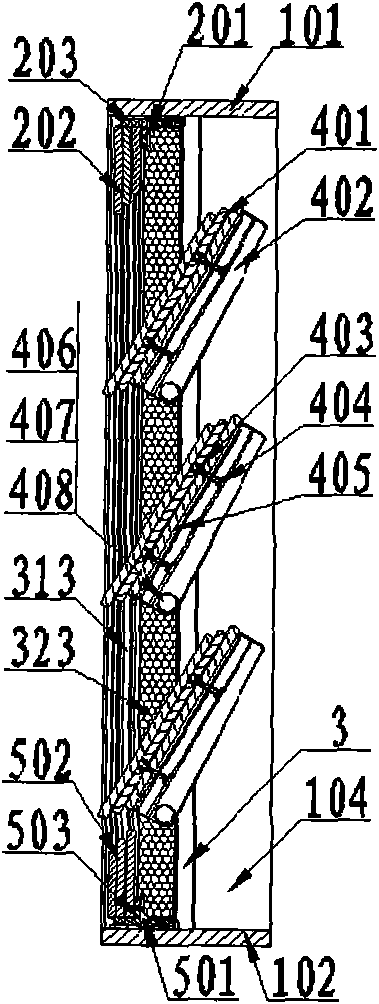

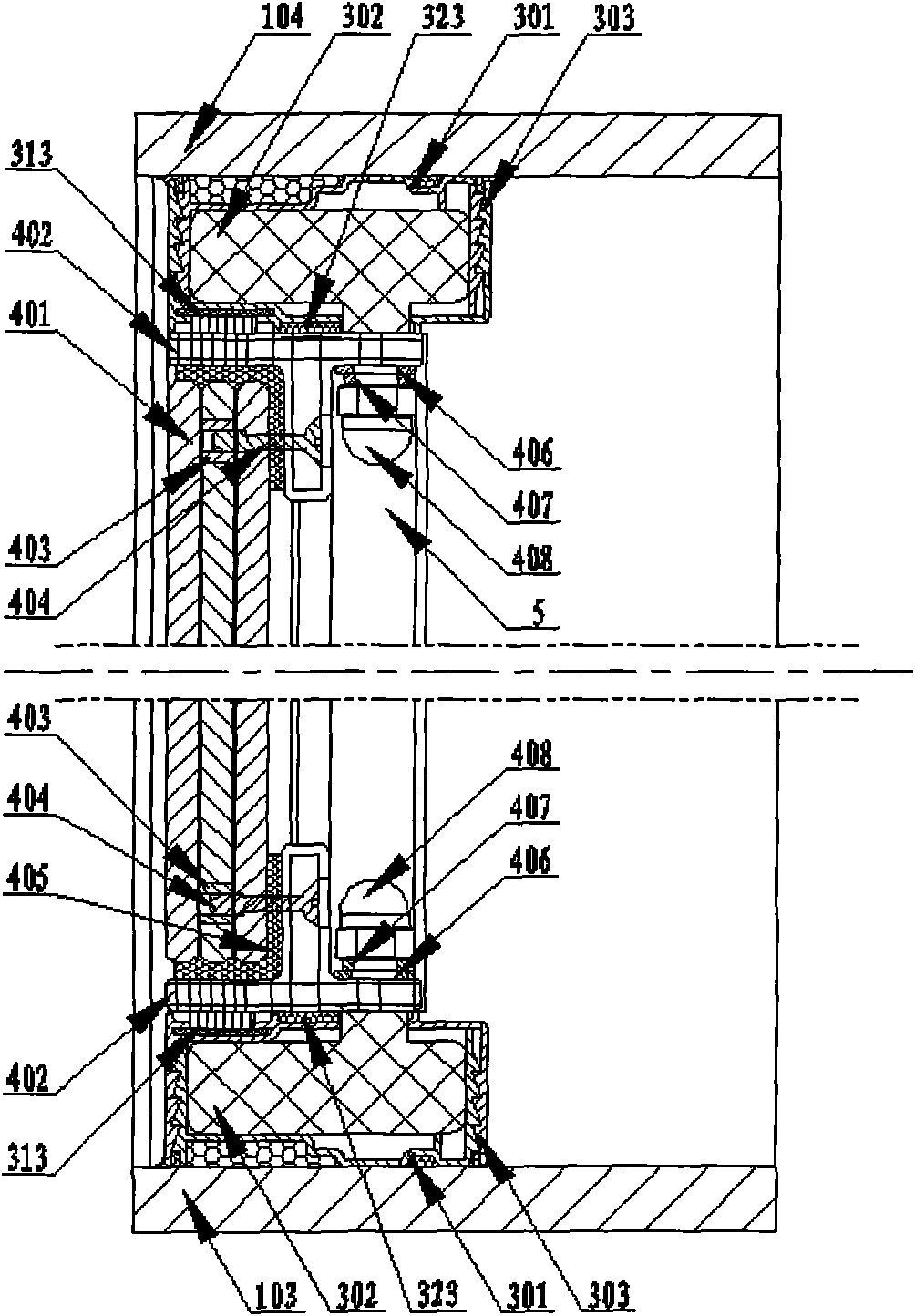

[0025] The universal window wall described in this embodiment is composed of a frame 1 , an upper rail 2 at the wrong opening, a linkage column 3 , a sheet 4 at the wrong opening and a lower rail 5 at the wrong opening.

[0026] The frame 1 is composed of an upper frame 101, a lower frame 102, a left frame 103 and a right frame 104 to form a rectangular basic structure, and the joints between the frames are fixedly connected to form the frame 1. The material of the frame is solid metal material or non-metallic solid material. Such as: stone, glass, metal, wood, plastic, tile, cement. Existing building walls can also be used as the frame of the frame 1 . In addition to the above rectangular basic structure, it can also be similar t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap