Diaphragm booster pump with constant-pressure structure

A diaphragm pressurization and constant pressure technology, which is applied to pumps with flexible working elements, pumps, liquid variable capacity machines, etc., can solve the problems of increasing water pressure, reducing water flow, increasing water flow, etc., and achieves easy installation and application , Saving the valve seat of the pressure limiting valve and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

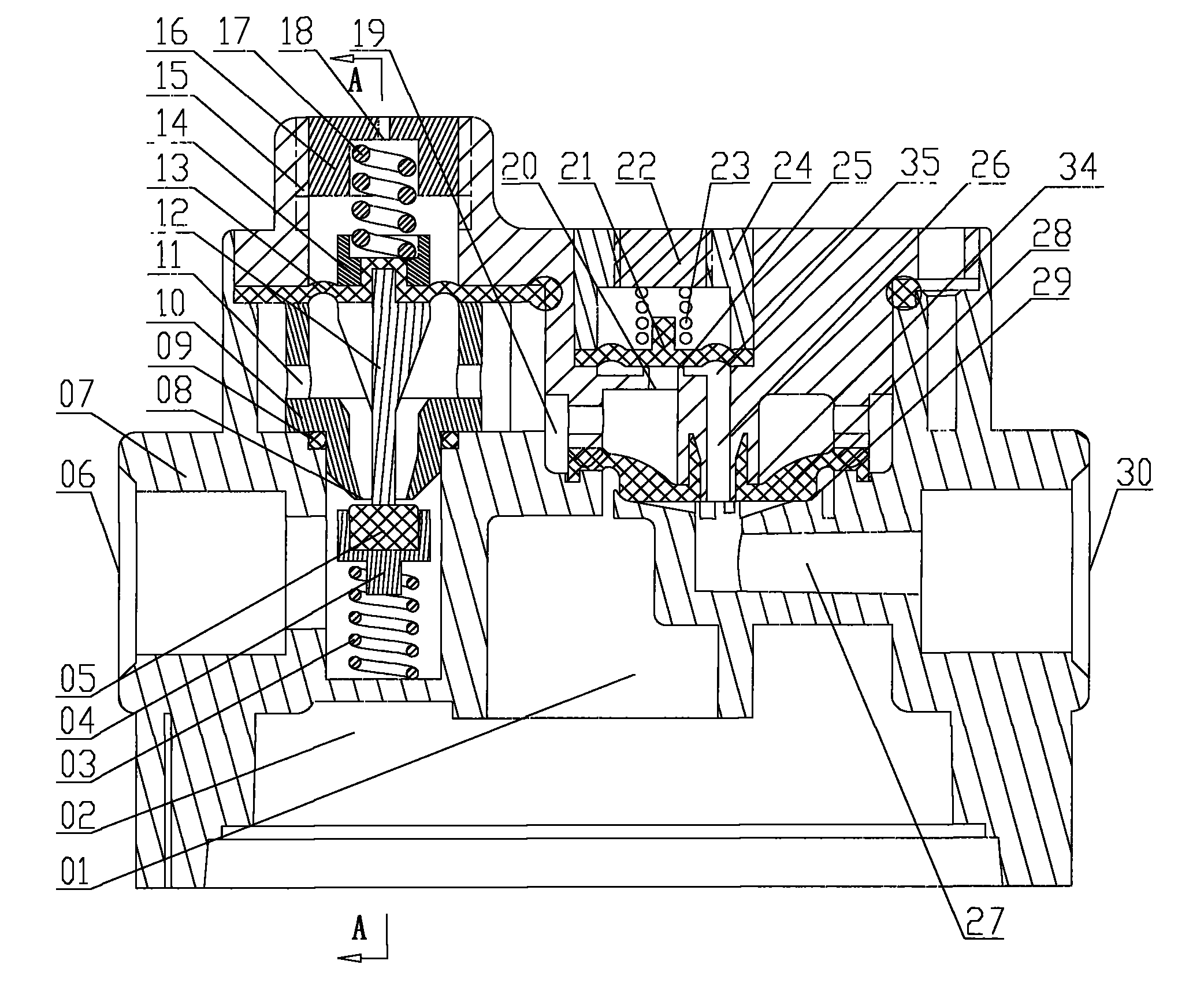

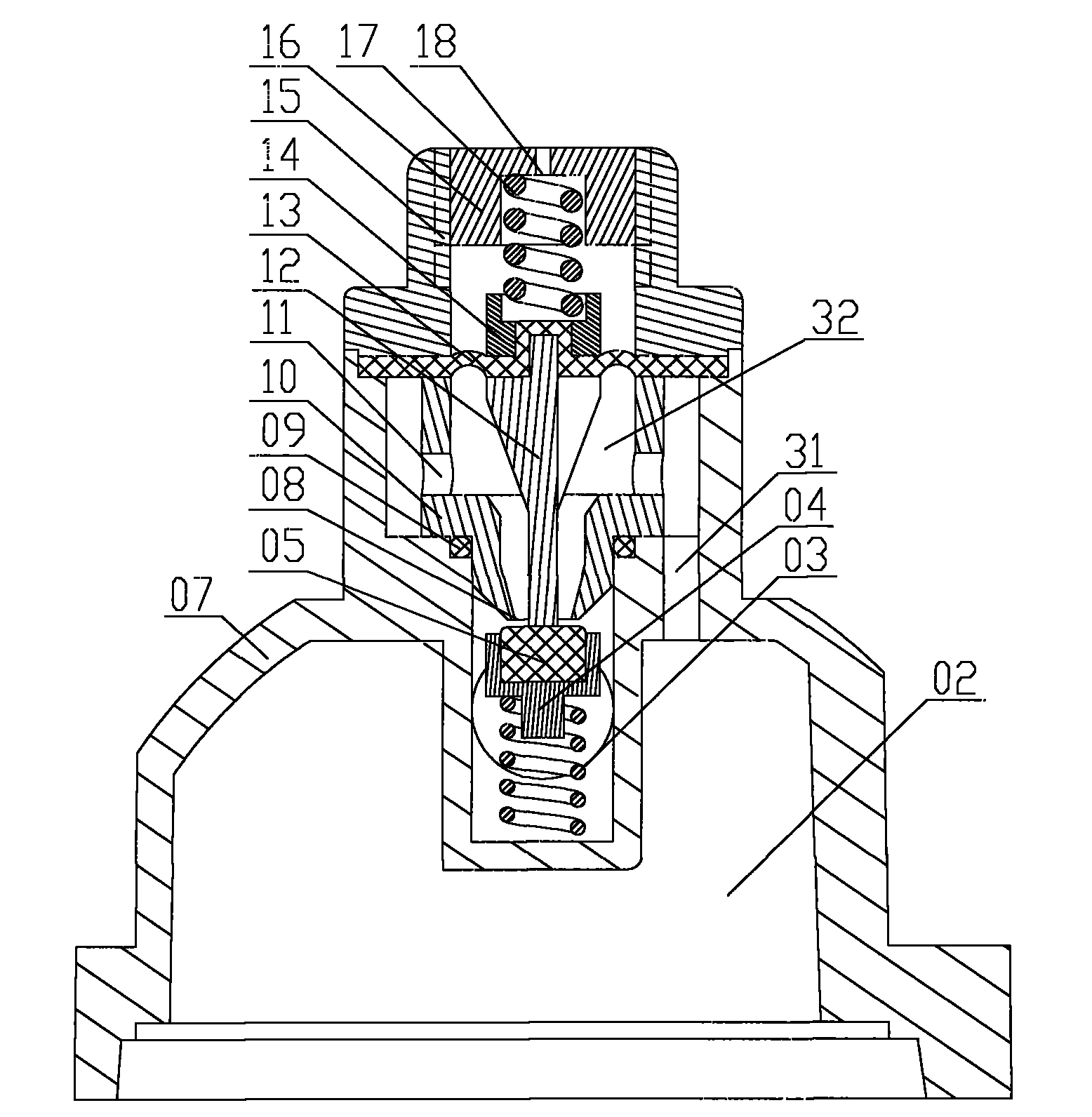

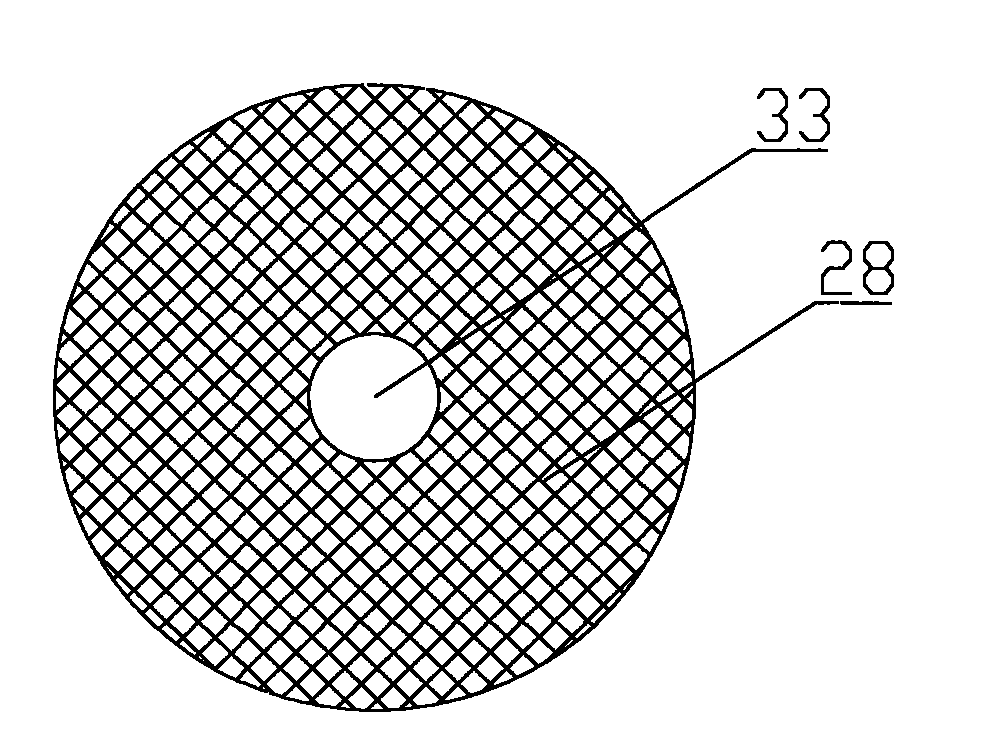

[0018] refer to figure 1 , figure 2 , image 3As shown, the diaphragm booster pump with a constant pressure structure of the present invention includes a pump head body 07 with a high-pressure chamber 01 and a low-pressure chamber 02 inside. Connected, there is a pressure limiting component on the channel connecting the source water inlet 06 and the low pressure chamber 02, and the pressure limiting component includes a water compression ring arranged on the flow field where the source water inlet 06 is connected to the low pressure chamber 02 10. The hollow body of the water-passing compression ring 10 constitutes a pressure-limiting chamber 32, and there is a pressure-limiting sealing water port 08 provided on the body of the water-passing compression ring 10 between the lower end of the pressure-limiting chamber 32 and the source water inlet 06. The water tight pressure ring 10 and the pump head body 07 are sealed by the source water sealing ring 09. After sealing, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com