Self-boosting type 9-gear double-intermediate-shaft full synchromesh transmission

A technology of double countershafts and synchronizers, which is applied to the transmission device, gear transmission device, transmission device control, etc., can solve the problems of automatic power boosting of automobile gear shifters, and achieve various power take-off forms, large torque reserve coefficients, and crawling The effect of strong slope ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

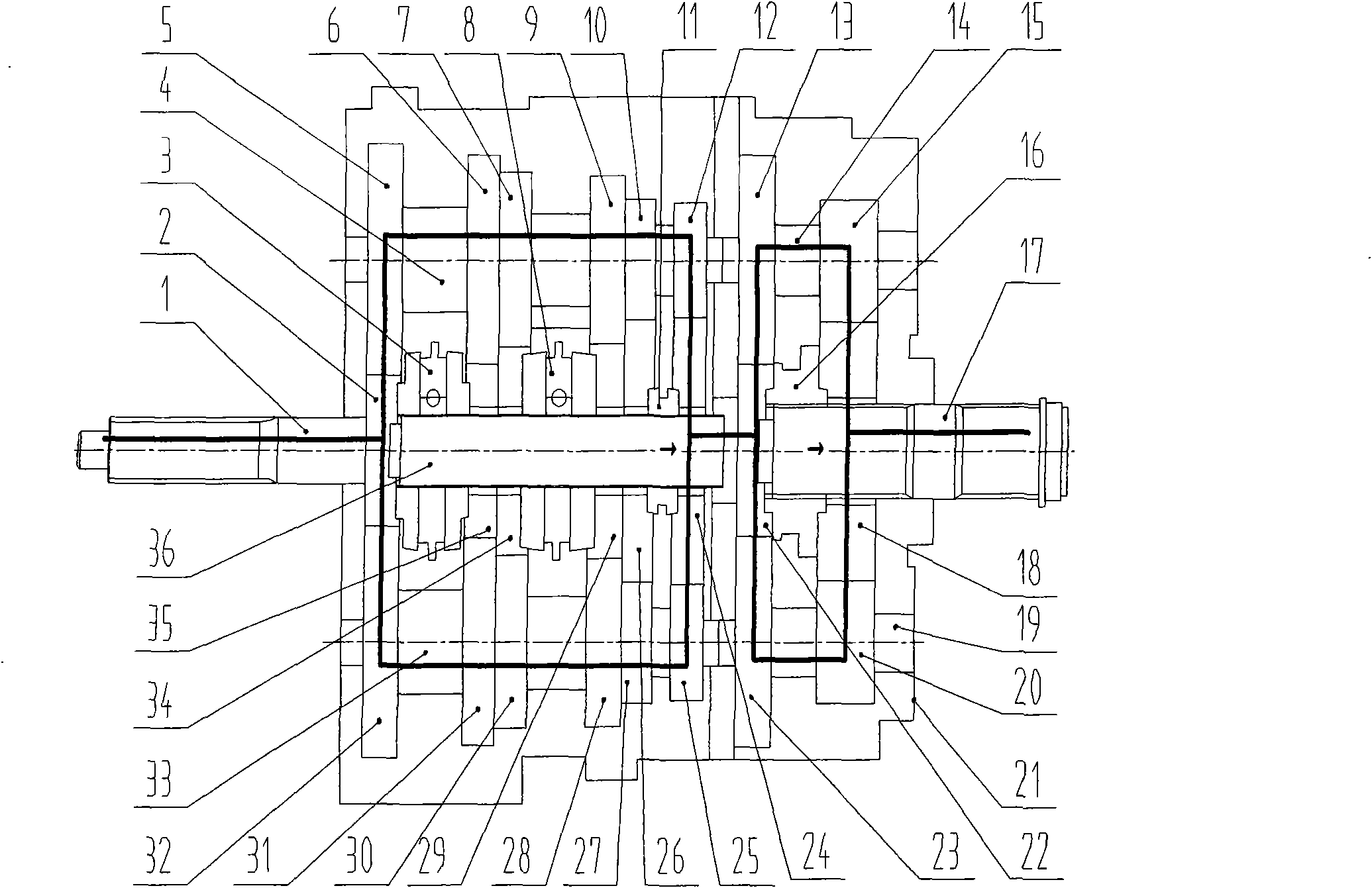

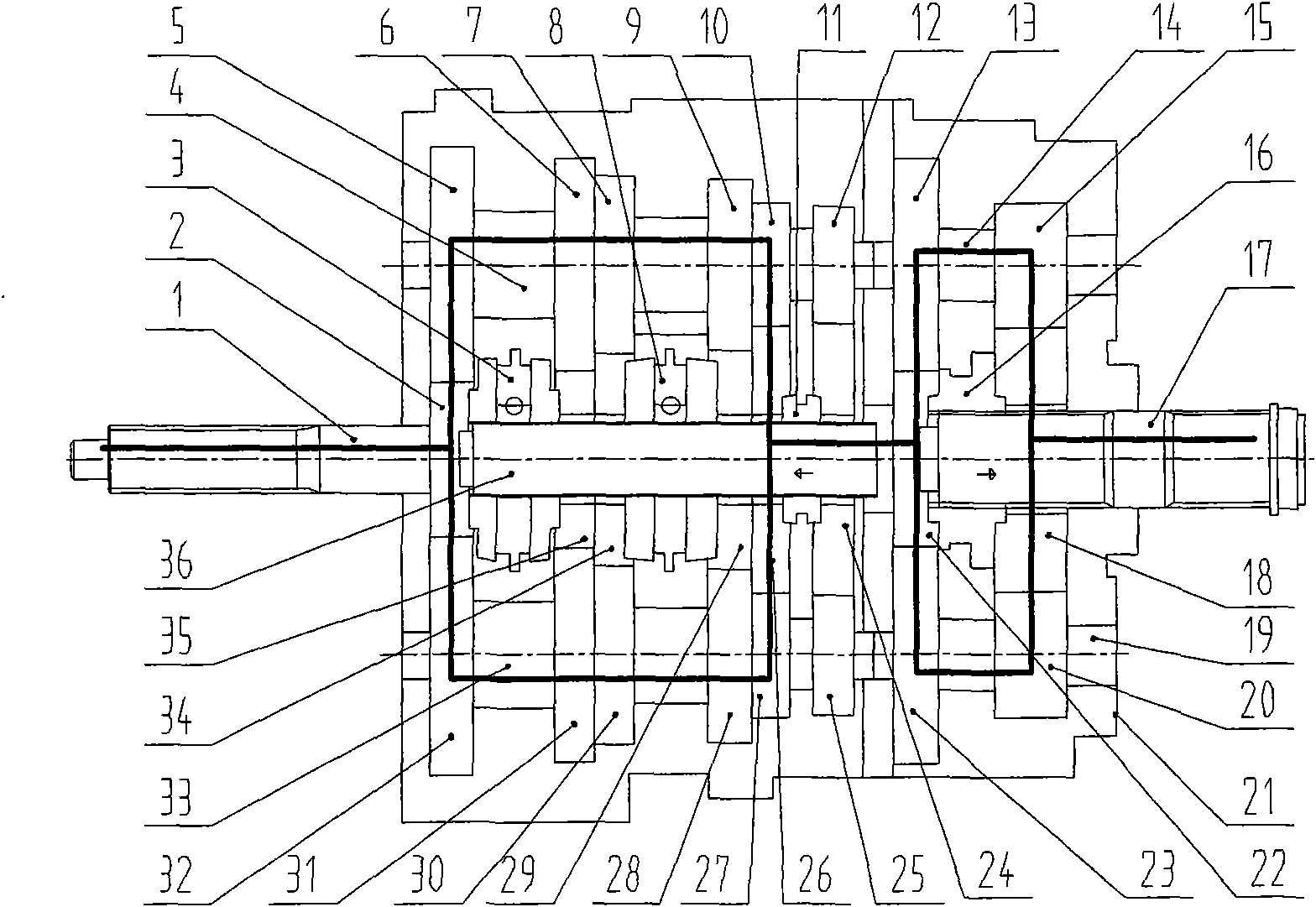

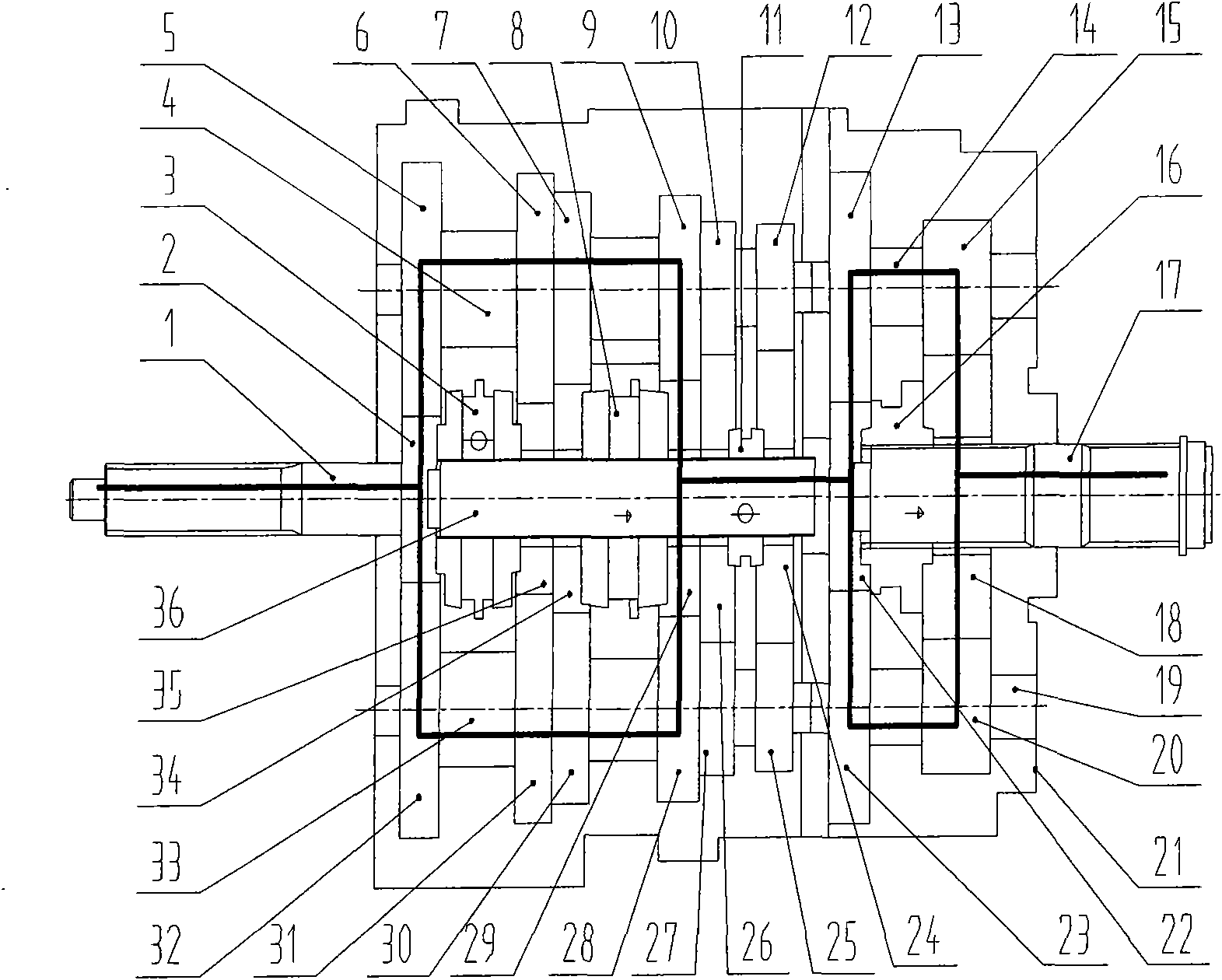

[0008] Take the RTS-11909A series transmission as an example: the RTS-11909A series transmission consists of a front five-speed main transmission and a two-speed auxiliary transmission. reverse gear. See the main structure diagram. In the main transmission, shaft 1 (input shaft) and shaft 1 gear 2 are connected by splines, and shaft 1 gear 2 can float in the radial direction. The gears on the intermediate shaft A are all matched with the intermediate shaft with a certain amount of interference and connected with crescent keys or long keys except that reverse gears 11, 22 and low gears 9, 25 are integrated with the intermediate shaft A. The gears 31, 30, 24 on the shaft B (main shaft) are supported on the shaft B by their inner diameters, and are in a floating state with the shaft B in the radial direction. They are positioned axially by means of a long hexagon key and a splined washer mounted on shaft B, and do not require adjusting shims. In the auxiliary transmission, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com