Suspension type medium-low speed permanent magnet suspension train motion control system and control method

A technology of maglev train and control system, applied in control system, vector control system, linear motor control and other directions, can solve the problems of fuzzy PID control unable to achieve the expected effect, system lag, etc. The effect of high efficiency and modularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

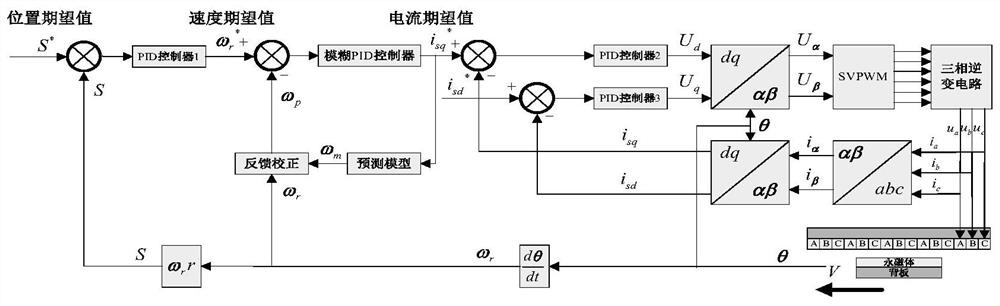

Method used

Image

Examples

Embodiment 1

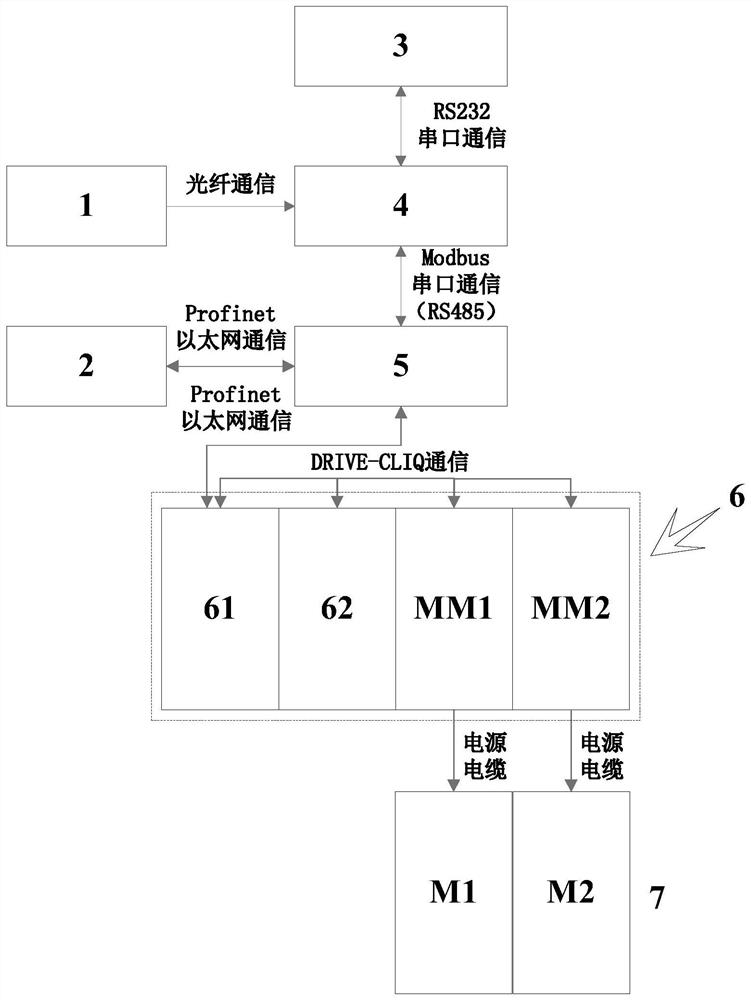

[0040] A motion control system for suspended medium and low-speed permanent maglev trains, such as figure 1 As shown, including host computer module, control unit module, motion control module and cross loop system 1;

[0041] Described upper computer module comprises KPT700 model touch screen 2 and IPC-610 main control computer 3; Described control unit module comprises control module 4 and PLC controller 5, and control module 4 adopts STM32F407 microcontroller, and PLC controller 5 selects Siemens S7 for use -1200 PLC; the motion control module includes a book-type S120 frequency converter 6, a permanent magnet linear synchronous motor 7 with a long stator without an iron core (two permanent magnet linear synchronous motors M1 and M2 are included in this embodiment);

[0042] The cross loop system 1 is communicatively connected to the control module 4 through an optical fiber interface, and is used to transmit the current position and speed information of the train to the co...

Embodiment 2

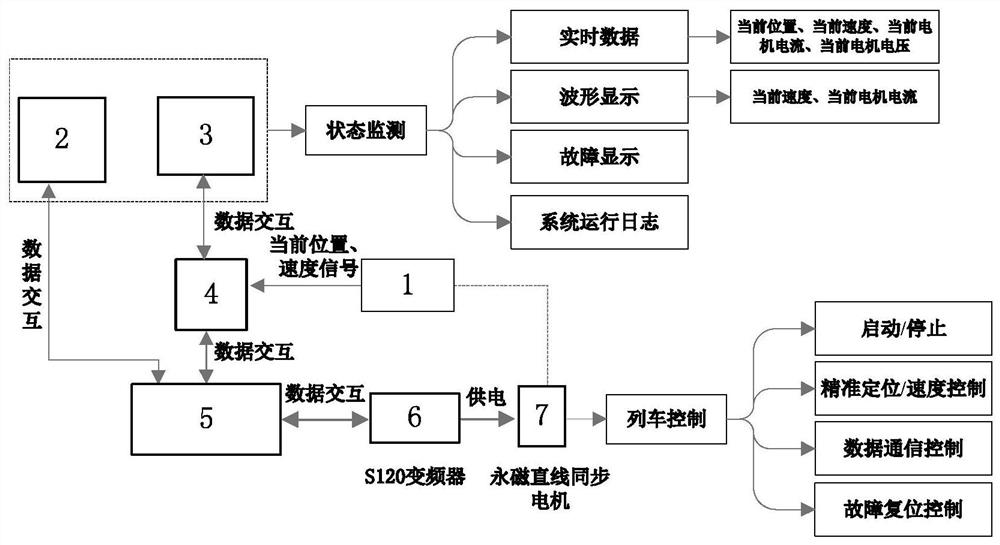

[0058] This embodiment provides a method for controlling a permanent maglev train using the control system described in Embodiment 1. In this embodiment, the permanent maglev train runs on the suspended permanent maglev test line between site one and site two, and the length of the suspended permanent maglev test line is X meters. Among them, QW78 means MM1 control word; QW102 means MM2 control word; QW80 means MM1 speed given; QW104 means MM2 speed given.

[0059] Such as Figure 5 As shown, the specific process is as follows:

[0060] 7) Once the permanent maglev train is parked at the station and ready to depart, the main control computer sends out dispatch command information, which includes target speed, target parking position and train start signal.

[0061] 8) The PLC controller receives the starting command information, controls the contactor KM1 and KM2 contacts to pull and sends a message control word to the S120 inverter: QW78=16#47F (motor start), target speed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com