Optical fiber clamp

An optical fiber and fixture technology, which is applied in the field of optical fiber fixtures with low stress and low micro-bending loss, can solve the problems of inconvenient operation and large volume of the optical fiber fixture, and achieve the effects of uniform cross-sectional distribution, small stress, and small micro-bending loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

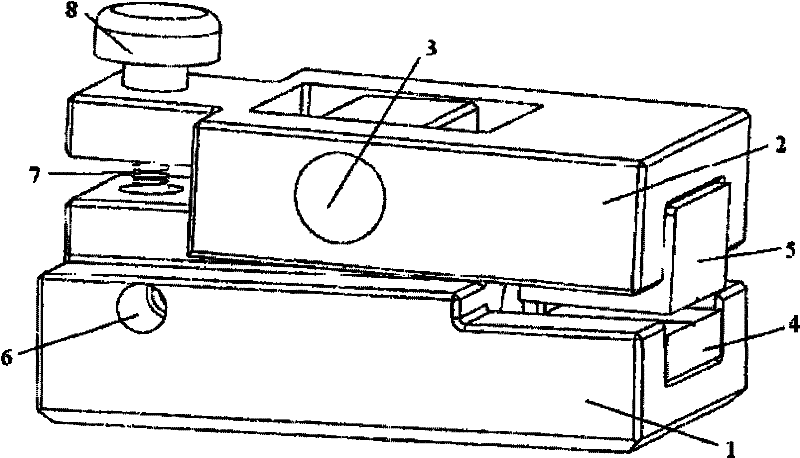

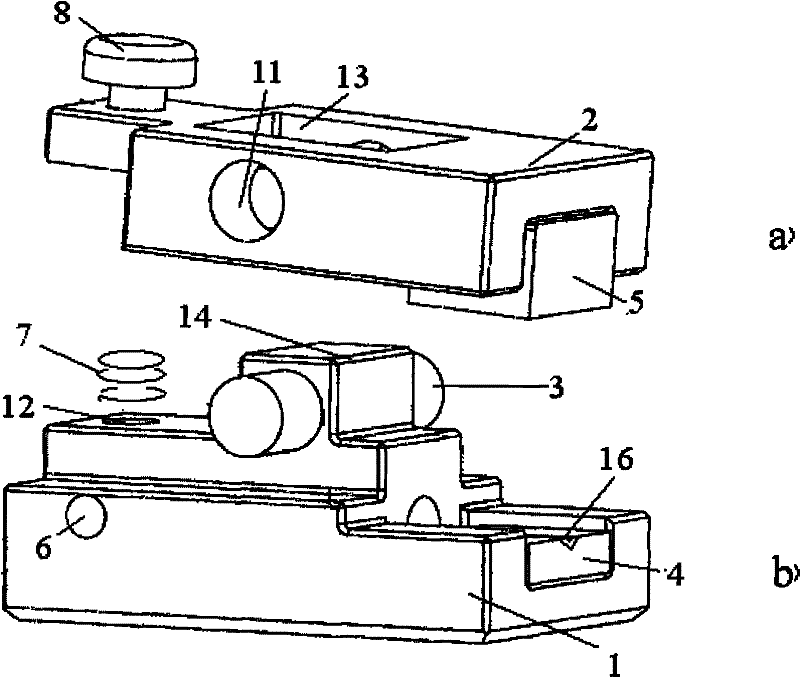

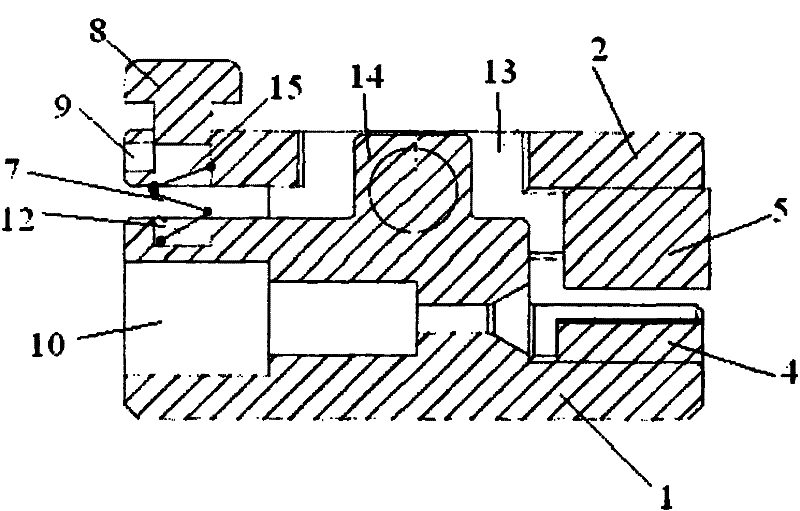

[0010] Referring to the accompanying drawings, the optical fiber clamp of the present invention includes: a base 1 and a top cover 2, the base 1 has a square convex body 14, the top cover 2 has a square through hole 13 for the square convex body 14 on the base to be inserted, the square convex body The body 14 is equipped with a horizontal bar 3, and the two ends of the horizontal bar 3 extend into the through holes 11 on both sides of the square through hole 13. The base and the top cover are swingable with the horizontal bar 3 as a lever support, and the rear end of the base 1 has an opening. Upward groove, there is a first rubber gasket 4 in the groove, the rear end of the top cover 2 has a downward groove, there is a second rubber gasket 5 in the groove, and there is a fiber optic FC head on the base 1. The stepped axial hole 10 is inserted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com