Crimping terminal of collector belt

A terminal and card cover technology, which is applied in the direction of connection, contact parts, clamping/spring connection, etc., can solve the problems of large size, trouble, and tools for connecting the bus belt, and achieve reliable wiring, safe work, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

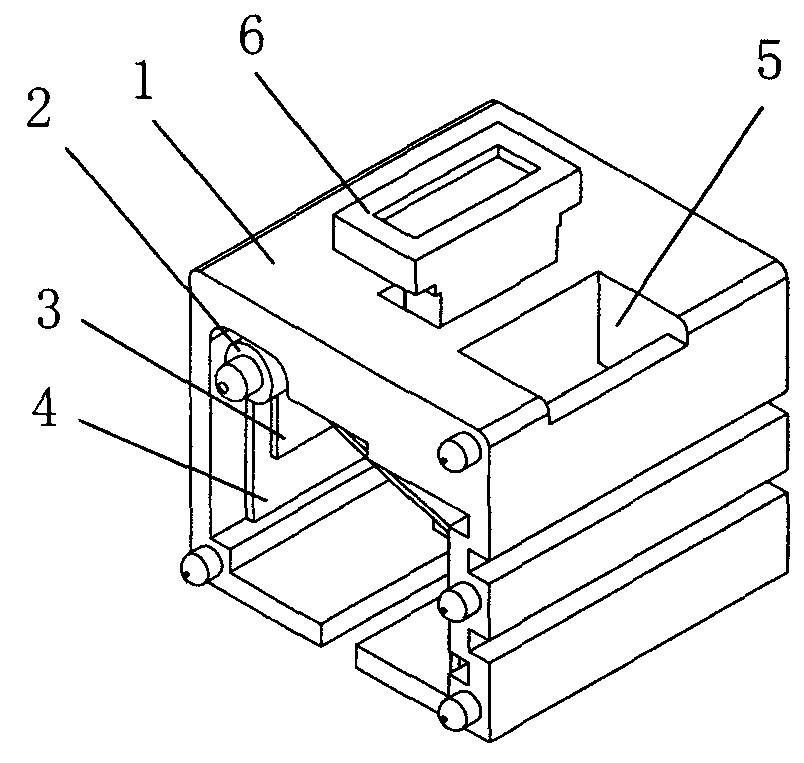

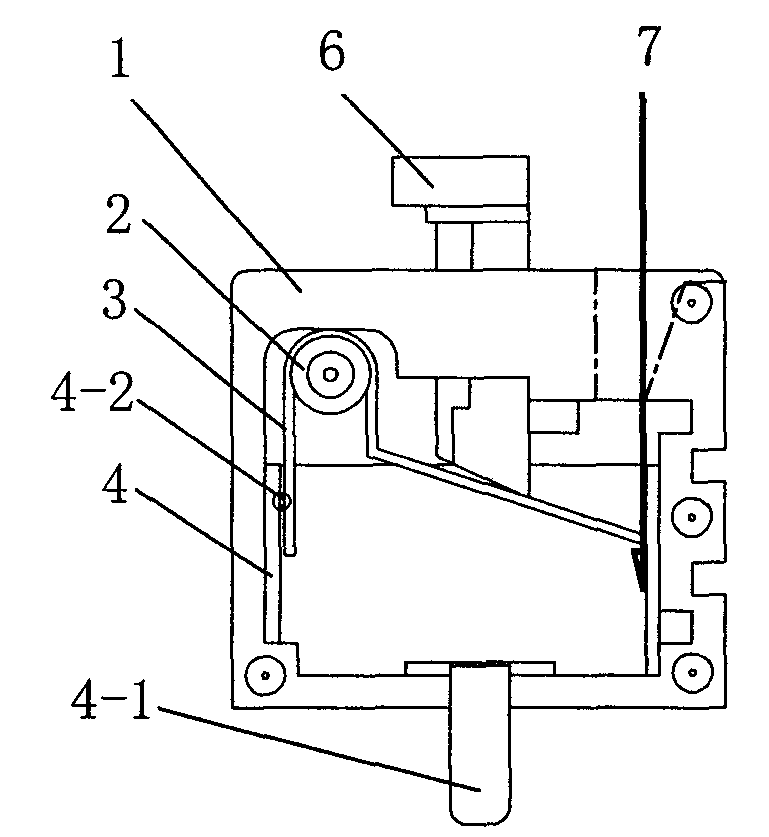

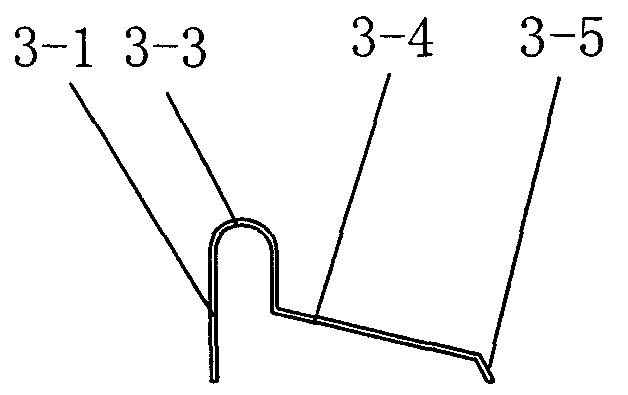

[0017] The busbar crimping terminal of this embodiment is as figure 1 , figure 2 As shown, a cavity is formed inside the insulating card cover 1 with an opening on one side, and the terminal body is formed after the end cover covers the opening. The conductive card holder 4 and the clamp spring 3 are arranged in the insulating card cover 1 . Conductive deck 4 such as Figures 6 to 8 As shown, the conductive metal is bent into a "gate" shape, with a first surface 4-3, a second surface 4-4 opposite to the first surface, and a connecting surface 4-5 connecting the first surface and the second surface . Positioning bumps 4-2 are formed on the first surface 4-3. When installed, the conductive card base 4 is clamped on the inner wall of the insulating card cover 1, and extends from the bottom of the insulating card cover 1 to an extended end 4-1 for connecting with the printed board. Circlip 3 such as Figures 3 to 5 As shown, it is composed of a vertical surface 3-1 and an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com