Outlet structure of power line for driving motor of electric vehicle

A technology for driving motors and electric vehicles. It is applied in the direction of electric vehicles, motors, and electric components. It can solve the problems of reduced heat dissipation performance, high cost of mold opening, and small size of permanent magnet motors, so as to improve the sealing performance and protection level. Improving the performance of the motor and improving the performance of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this case, the same components are provided with the same reference numerals.

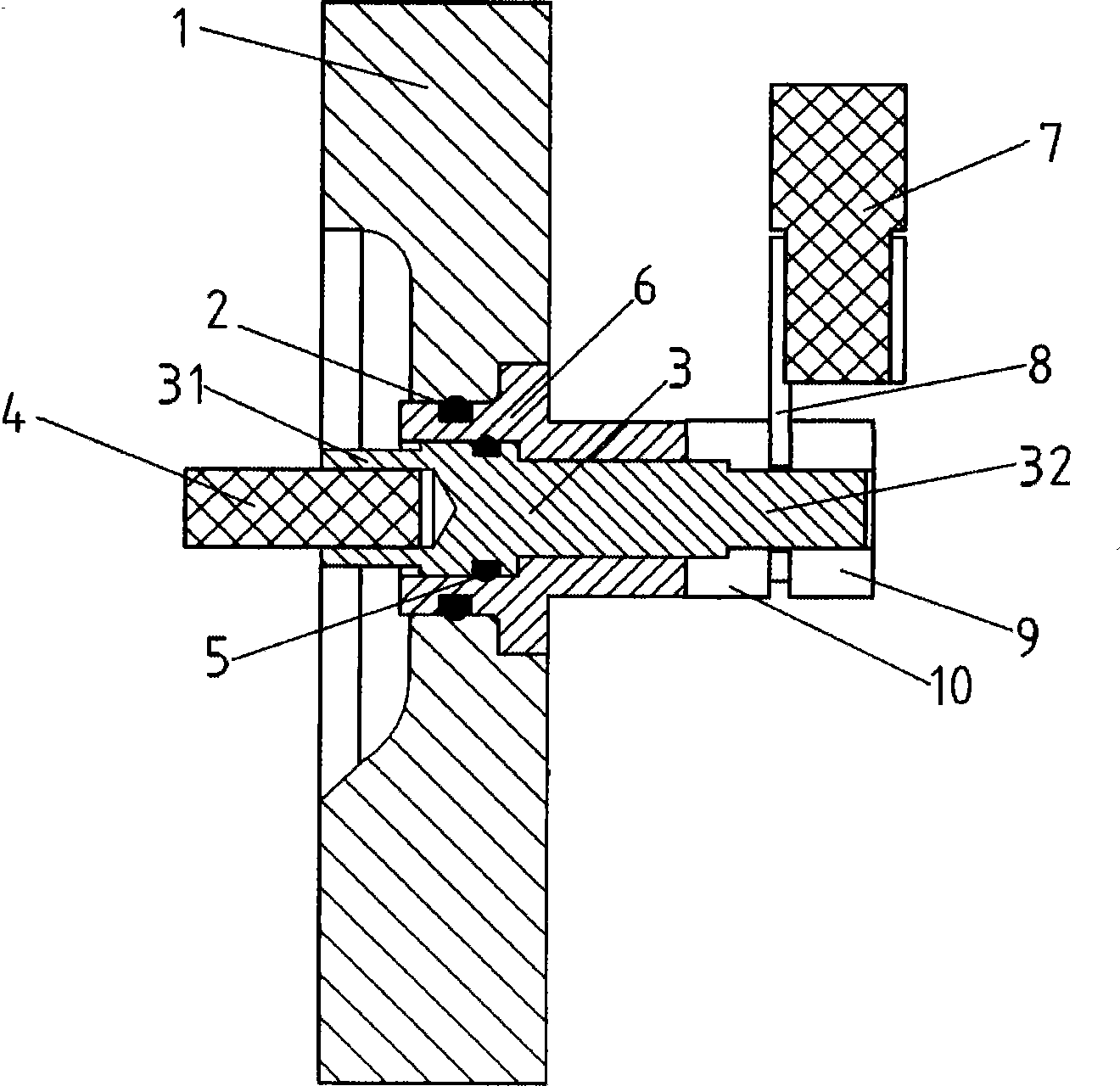

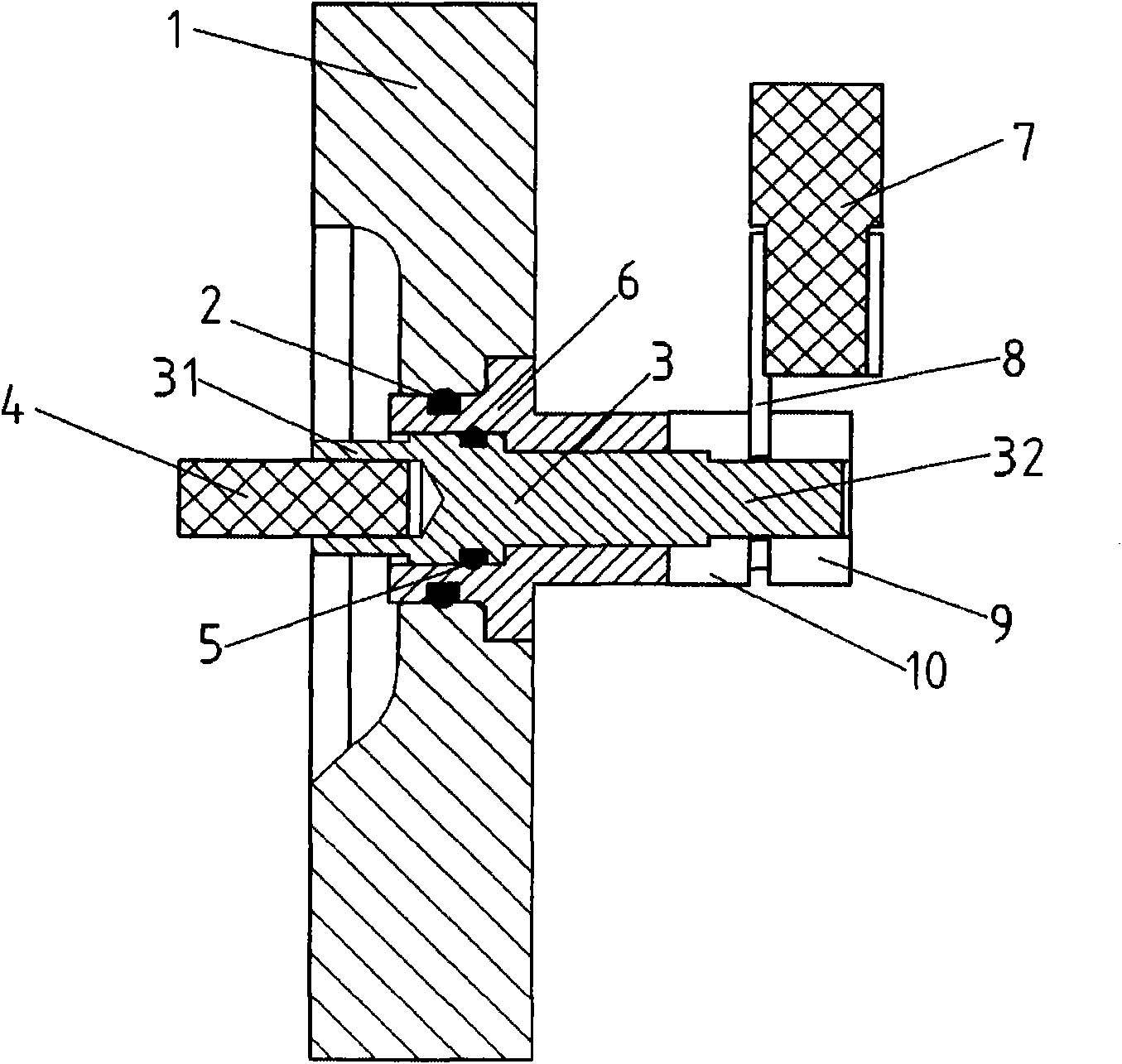

[0027] See figure 1 As shown, the electric vehicle drive motor power line outlet structure of the present invention includes a terminal 3 and an insulating adapter 6, the terminal 3 includes a first end 31 and a second end 32, and the insulating adapter 6 passes through The end cover 1 of the overdrive motor (not shown) is sealed and fixedly connected with the end cover 1, and the terminal post 3 passes through the insulating adapter 6 and is sealed and fixedly connected with the insulating adapter 6. The first end portion 31 is located inside the driving motor and is electrically conductively connected to the lead wire 4 of the driving motor, and the second end portion 32 is located outside the driving motor and is electrically conductively connected to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com