Marking and/or leveling device

A technology for leveling and marking, which is used in measuring devices, active optical measuring devices, measuring instruments, etc., and can solve the problems of high structure, cumbersome and high cost of pendulum system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

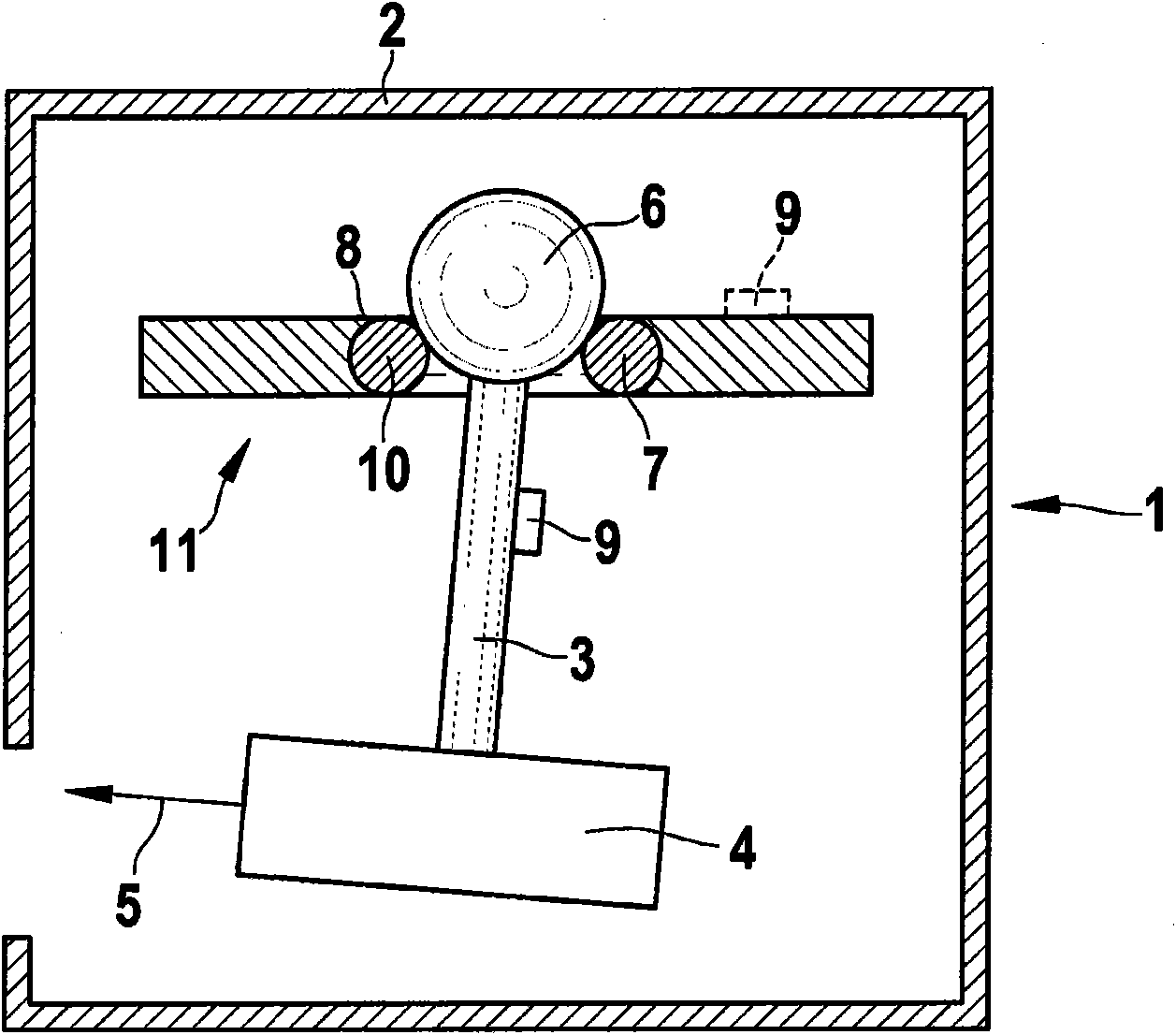

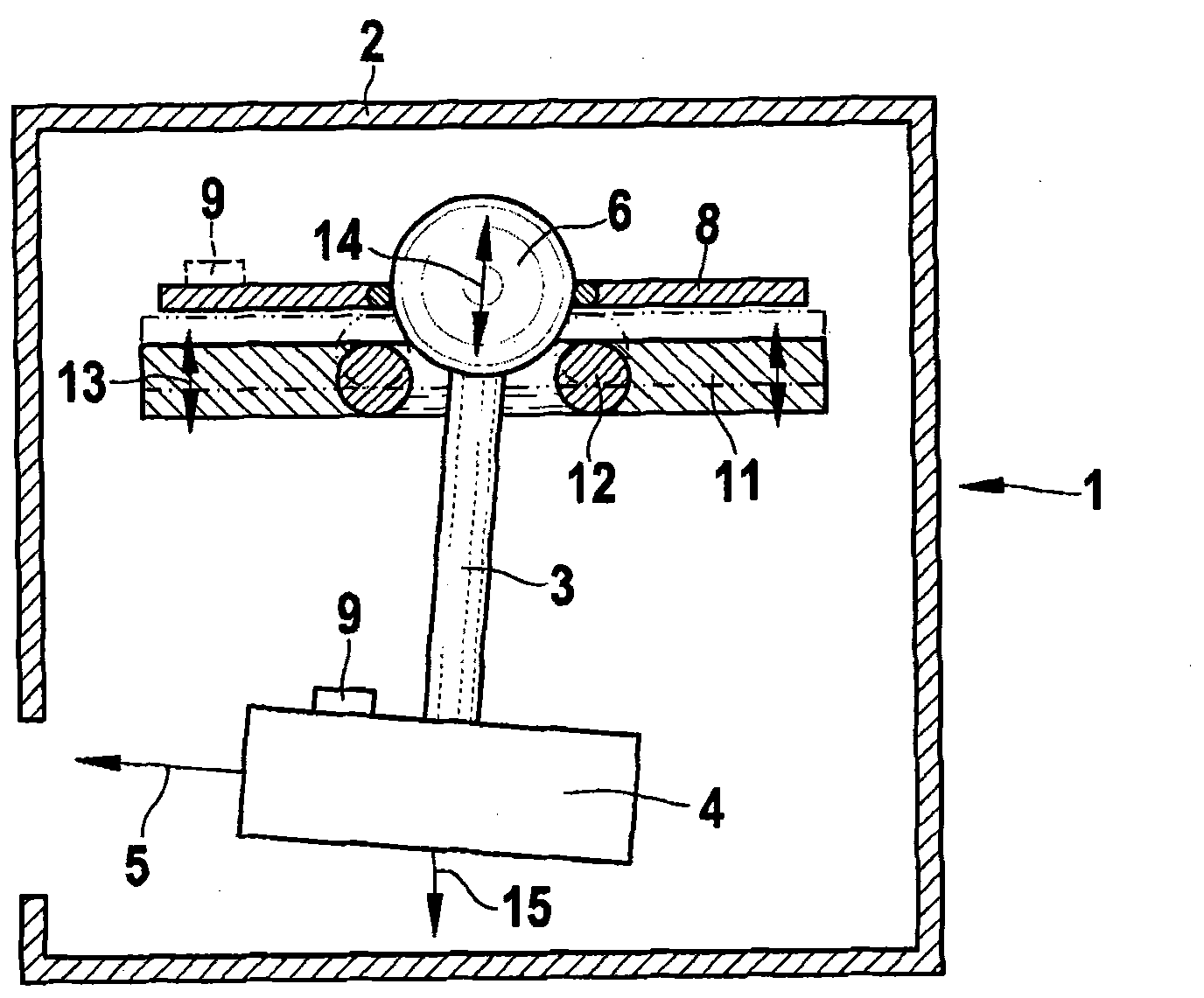

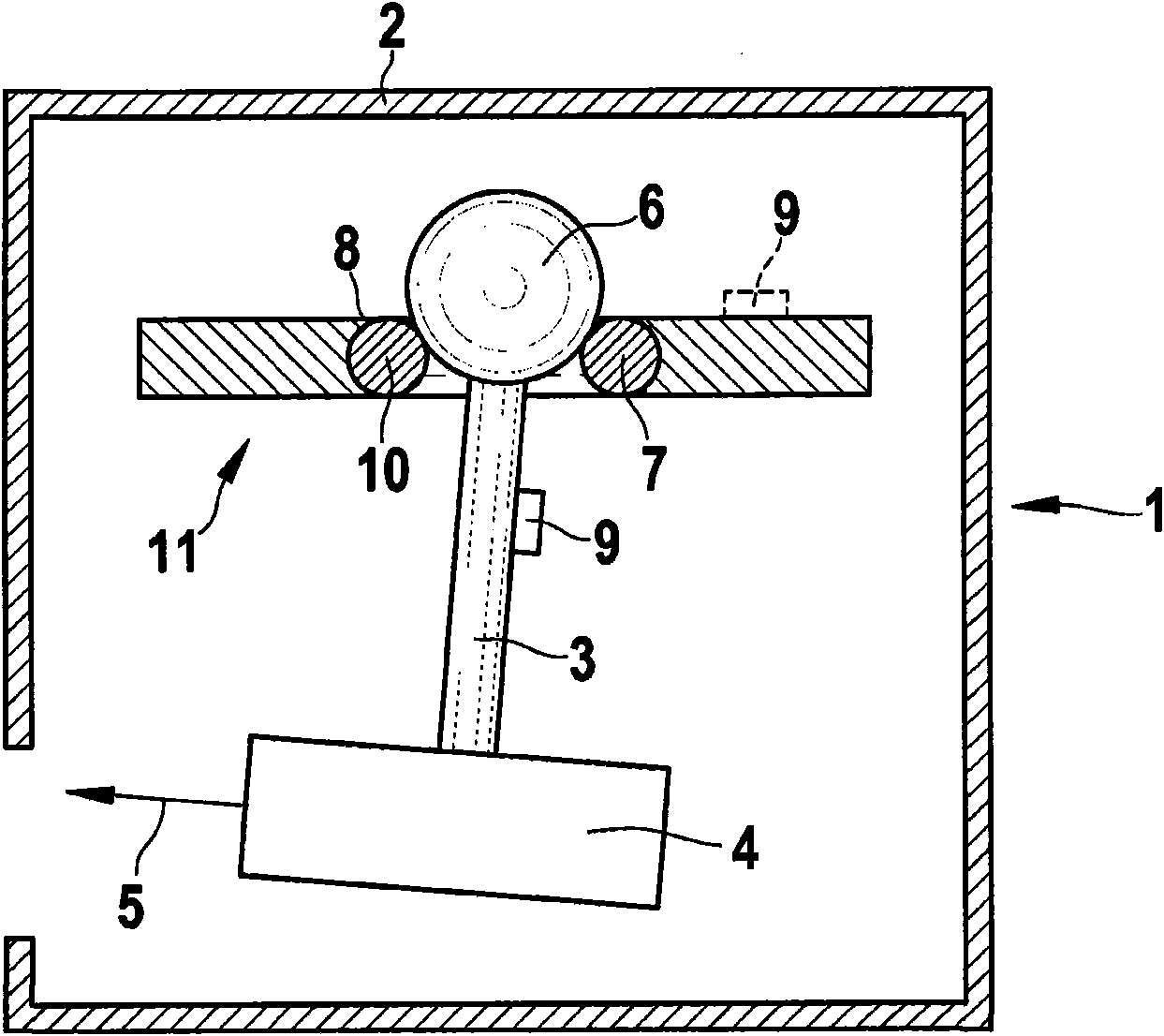

[0018] In the figures, identical structural elements and structural elements having the same function are identified with the same reference numerals.

[0019] exist figure 1 The marking and / or leveling device 1 is shown schematically in FIG. The marking and / or leveling device comprises a housing 2 and a pendulum 3 , which is mounted pivotably relative to the housing 2 in all spatial directions relative to the housing 2 . The pendulum 3 is designed as a rigid linkage element and carries, on its lower end in the plane of the drawing, a light source 4 designed as a laser diode for generating a point-shaped or linear laser beam 5 along the cross-section. , with which a point-shaped or linear horizontal laser line can be projected onto the projection plane.

[0020] At the upper end facing the light source 4 in the plane of the drawing, the rigid pendulum 3 has a ball head 6 which, together with the annular bearing receptacle 7 , forms a self-aligning bearing 8 . The bearing re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com