Dig-pull type cassava harvester

A harvester and cassava technology, applied in the direction of digging harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of poor rigidity and stability, no further reports in practice, etc., and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

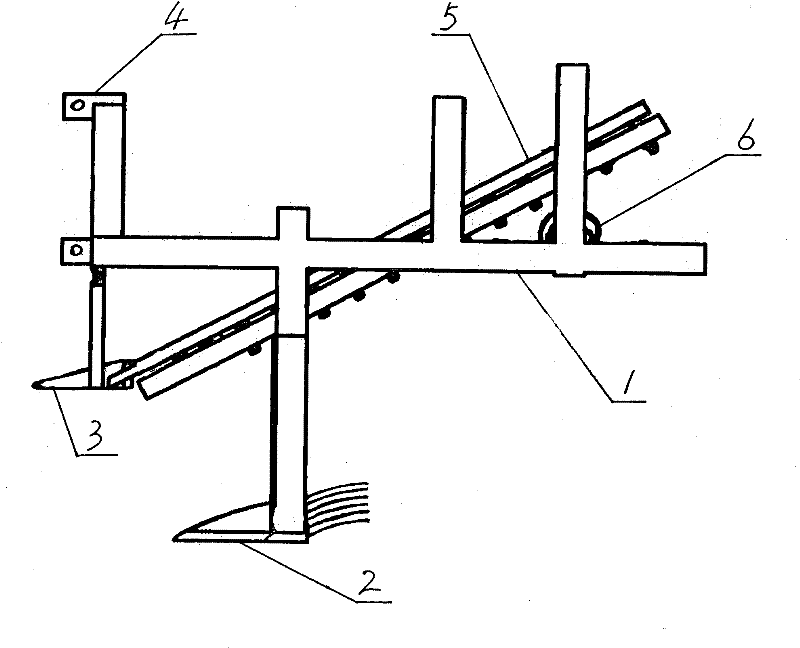

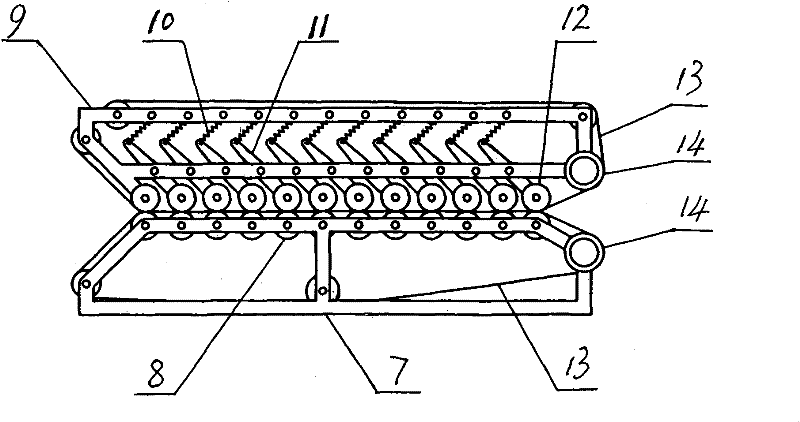

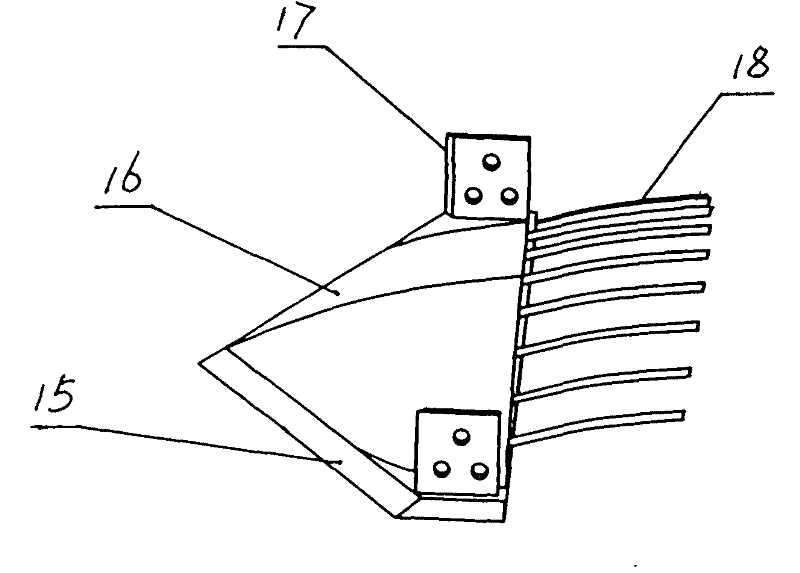

[0026] exist figure 1 In the shown structure, the present invention comprises a frame 1, a suspension device 4 is provided in front of the frame, an excavating shovel 2 is fixedly connected below the frame, and a clamping and conveying device with a low front end and a high rear end is set on the frame 5. The clamping and conveying device 5 is connected with the power source of the tractor through the transmission device, guide blocks 3 are arranged on both sides of the front end of the clamping and conveying device, and a disc cutting knife and The potato cutting device 6 that motor is formed. When harvesting cassava, first cut off the cassava stalk above 30cm on the ground and remove debris, hang the frame 1 on the tractor, and be driven by the tractor to move forward. The digging shovel 2 on the frame cuts in from below the potato block, Dig loosely, raise the tuber root at the same time, then guide the cassava stalk to the clamping and conveying device 5 by the guide bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com