Prestressed tube tensioning mold

A prestressed tube and tensioning technology, applied in the direction of molds, etc., can solve the problems of high damage rate of screw and clamping screw fittings, high labor intensity for mold assembly and disassembly, and low utilization rate of molds, so as to reduce labor intensity and time. The effect of ensuring effective travel and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

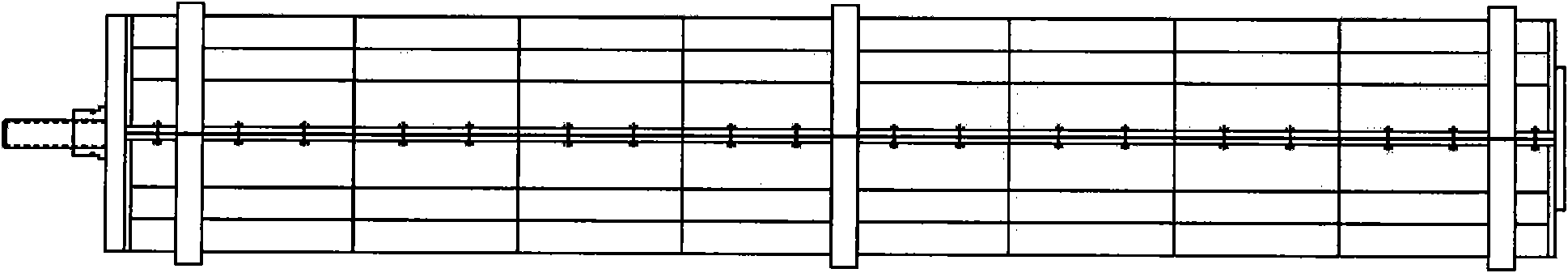

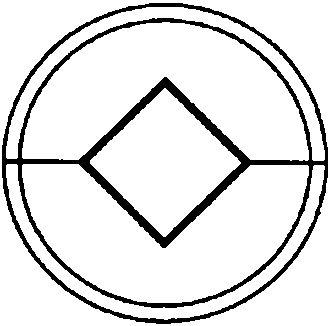

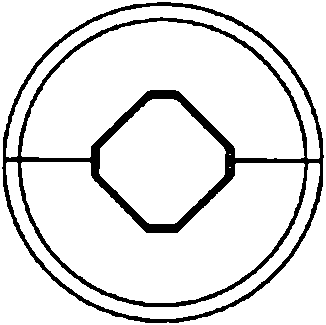

[0029] see Figure 1-Figure 2

[0030] The mold includes an upper mold and a lower mold, and the upper mold and the lower mold are fastened to each other, and an inner mold is also arranged inside the mold formed by the upper and lower molds. The material of the mold can be metal material, high molecular polymer material, metal and polymer composite, etc.; its material has the characteristics of high strength, good high temperature stability, and alkali corrosion resistance; it can break the singleness of centrifugal concrete mold material Limitations, reduce production costs, improve mold technical parameters, eliminate local deformation caused by mold assembly, etc. A variety of concrete products refer to the shape of the longitudinal cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com